If you want to CNC machining titanium, people often need more time to think about how to machine titanium alloys will be easier. Because it has always been challenging to process titanium alloys by wire cutting, wire cutting is the best processing method. So why is it challenging to process titanium alloys by wire cutting?

To solve this problem, we must first understand some common metal properties of titanium alloys.

What is titanium alloy?

Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide has an impurity content of no more than 0.1%, but it has low strength and high plasticity. The properties of 99.5% industrial pure titanium are density ρ=4.5g/cm3, melting point 1725℃, thermal conductivity λ=15.24W/(m. K), tensile strength σb=539MPa, elongation δ=25%, section Shrinkage rate ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195.

What are the properties of titanium alloys?

- High specific strength

The density of titanium alloy is generally about 4.51g/cm3, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel, and some high-strength titanium alloys exceed the strength of many alloy structural sheets of steel. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts with high unit strength, good rigidity, and light weight can be produced. Titanium alloys are used in aircraft engine components, skeletons, skins, fasteners, and landing gear, as well as some aerospace components.

- High thermal strength

The operating temperature is several hundred degrees higher than that of aluminum alloys, and the required strength can still be maintained at moderate temperatures. It can work for a long time at a temperature of 450 to 500 °C, while the specific strength of aluminum alloys decreases significantly at 150 °C. The working temperature of titanium alloy can reach 500 ℃, and the working temperature of aluminum alloy is below 200 ℃.

- Good corrosion resistance

Titanium alloy works in a humid atmosphere and seawater medium, and its corrosion resistance is much better than stainless steel; it has particularly strong resistance to pitting corrosion, acid corrosion, and stress corrosion; Goods, nitric acid, sulfuric acid, etc. have excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

- Good low-temperature performance

Titanium alloys can still maintain their mechanical properties at low and ultra-low temperatures. At extremely low temperatures, titanium alloys with extremely low interstitial elements, such as TA7, can still maintain certain plasticity at -253 °C. Therefore, titanium alloy is also an important low-temperature structural material.

- High chemical activity

Titanium has high chemical activity and produces strong chemical reactions with O, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than 0.2%, a hard TiC will be formed in the titanium alloy; when the temperature is high, a hard surface layer of TiN will also be formed when it interacts with N; when the temperature is above 600 ℃, titanium absorbs oxygen to form a hardened layer with high hardness; Increased hydrogen content will also form an embrittlement layer. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1 to 0.15 mm, and the degree of hardening is 20% to 30%. The chemical affinity of titanium is also large, and it is easy to adhere to the friction surface.

- Small thermal conductivity

The thermal conductivity of titanium λ=15.24W/(m. K) is about 1/4 of nickel, 1/5 of iron, 1/14 of aluminum, and the thermal conductivity of various titanium alloys is about 1/4 of that of titanium. down 50%. The elastic modulus of titanium alloy is about 1/2 of steel, so its rigidity is poor and easy to deform, so it is not suitable to make slender rods and thin-walled parts.

Summarize

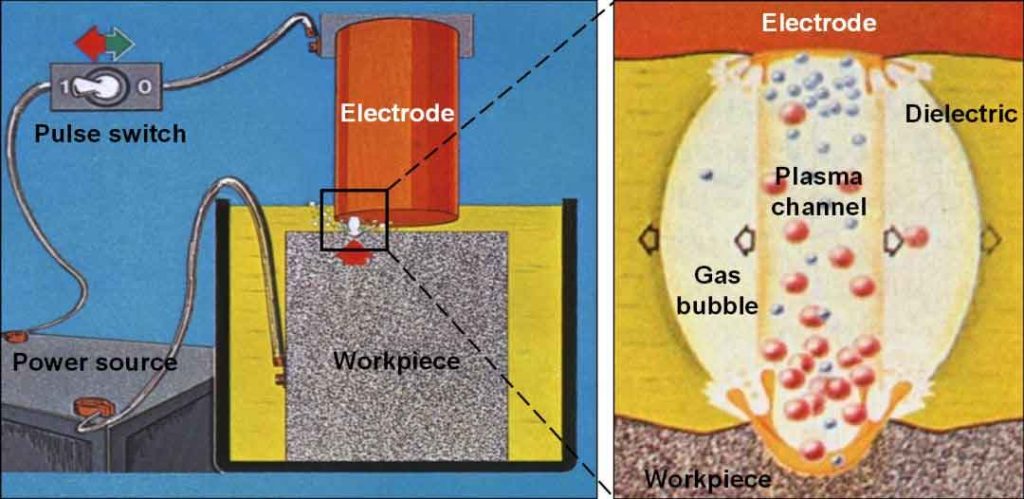

Therefore, according to the above metal properties of titanium alloys, we can know that titanium is a metal with high strength, high hardness, high heat resistance, and low thermal conductivity. Then the wire cutting process is through the phenomenon of electrical corrosion, the high-frequency discharge between the molybdenum wire and the workpiece, and the instantaneous high temperature melts the metal for cutting.

Titanium metal is very stable in the air at room temperature. Only when it is heated at a high temperature for some time will it change its color, and the most important thing is to turn blue. This is mainly because when metal titanium is heated in the air, it will oxidize with oxygen to form a dense oxide film.

This layer of the oxide film can not only protect the surface of titanium metal, but also the fundamental source of titanium color change. The reaction equation of titanium oxidation is Ti+O2==TiO2, and the reaction condition is high-temperature heating (ie, the heat-affected layer on both sides of the wire cutting slit). When the heating temperature is low, the oxide film on the titanium surface is almost transparent, which is difficult for people to perceive with the naked eye, but when the temperature rises, the oxide film in the pot will gradually thicken and interfere with light. Different colors appear in human eyes. Therefore, the thickness of the oxide film determines what color the titanium surface will turn into.