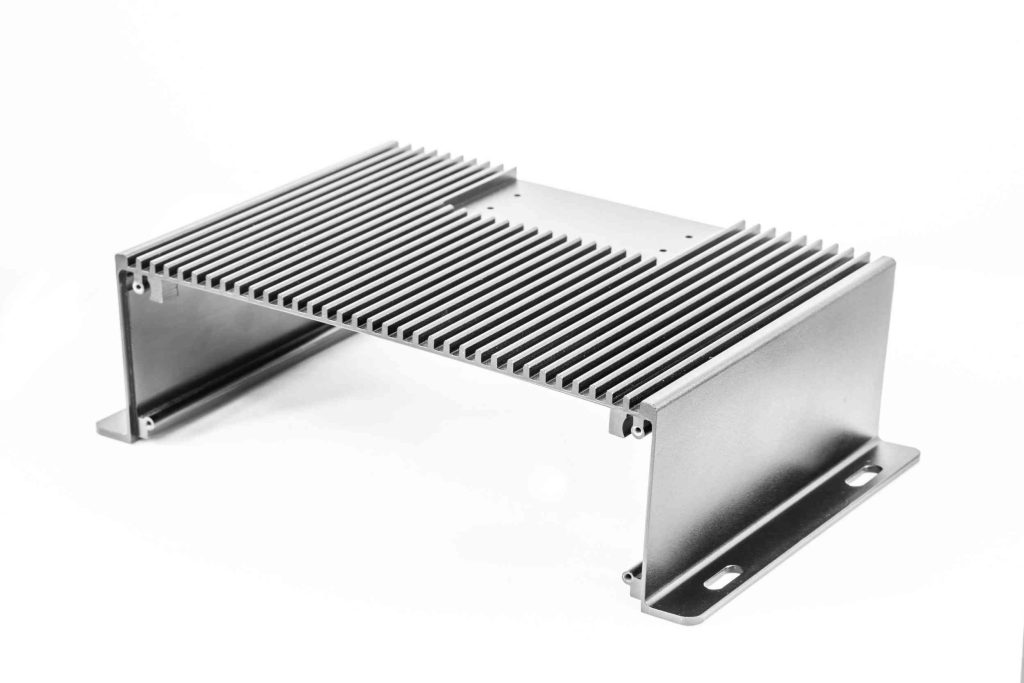

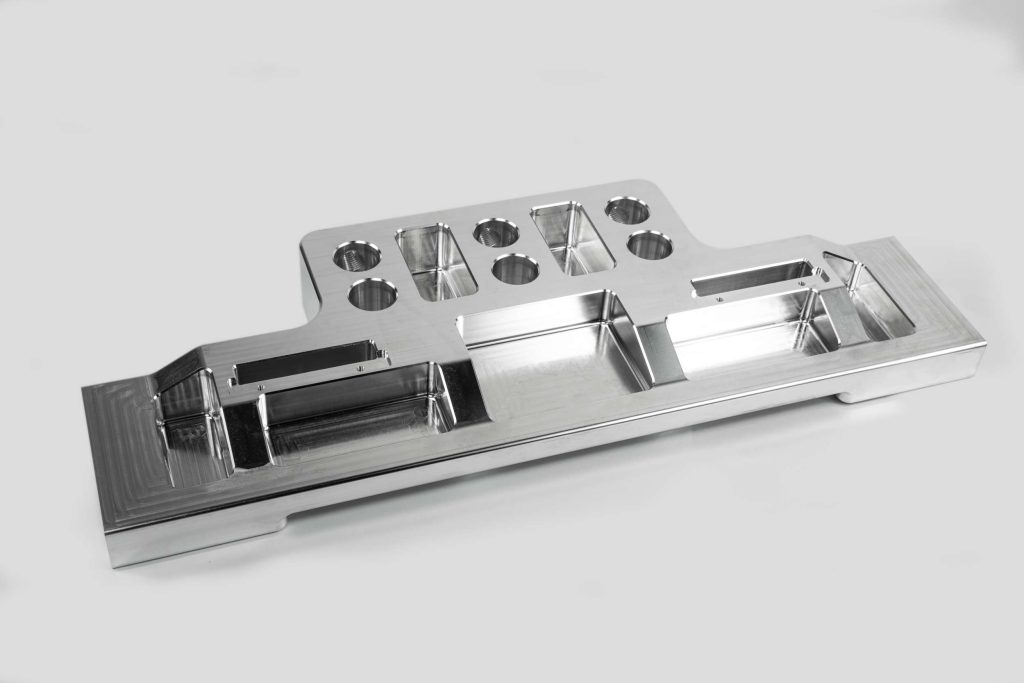

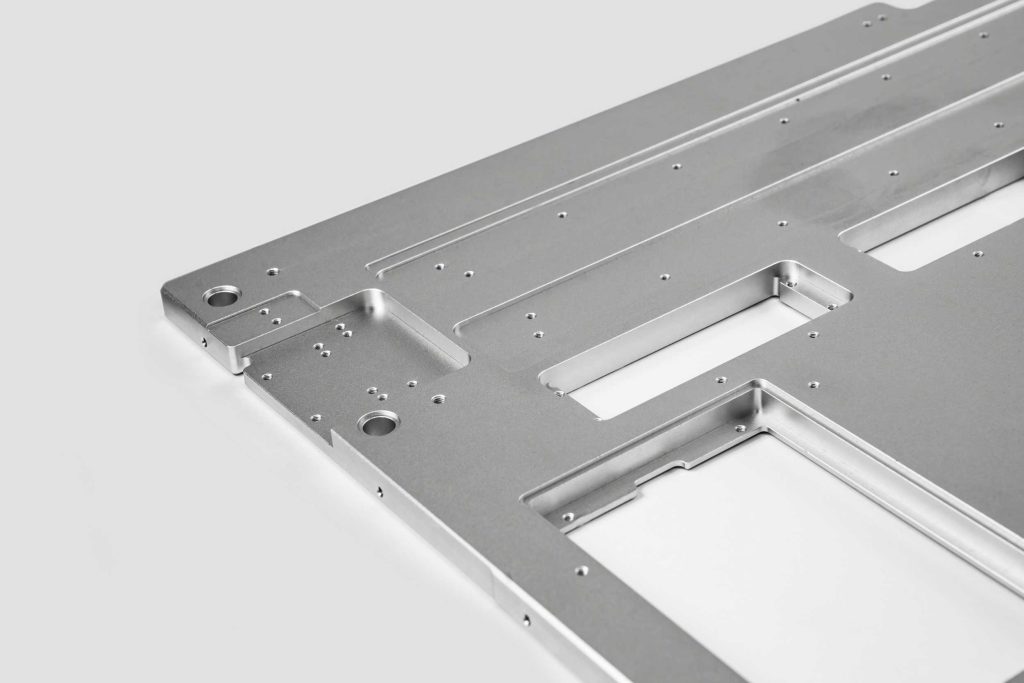

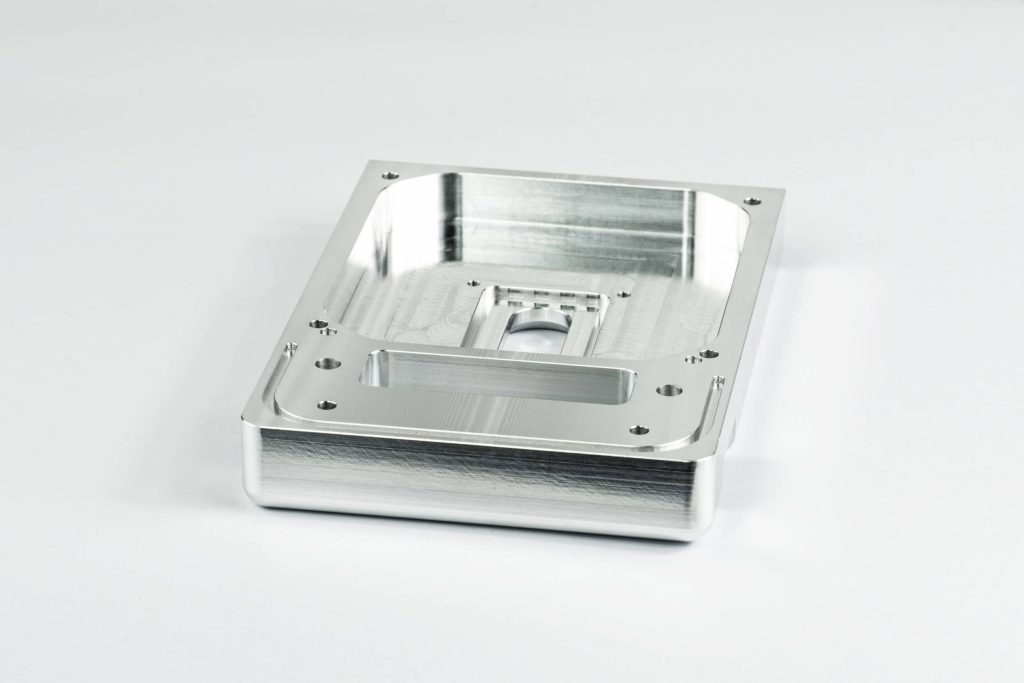

CNC Machining Aluminum Parts

Aluminum alloy precision parts and products are popular because of their lightweight and exquisite appearance, and they are more and more widely used in industry and daily necessities. Especially in recent years, with the development of science and technology and the progress of society, people’s demand for product diversity has become stronger and stronger. Therefore, the better the processing technology of aluminum alloy products, the more popular it will be, the greater the market demand and the higher the profit. CNC machining is one of the best machining methods for aluminum alloy shell products.

Strength of Aluminum in CNC Machining

1. Wide Applications

2. low in density and high in strength

3. Various Quality Aluminum Materials

4. Good electrical conductivity

5. Cost-effective production

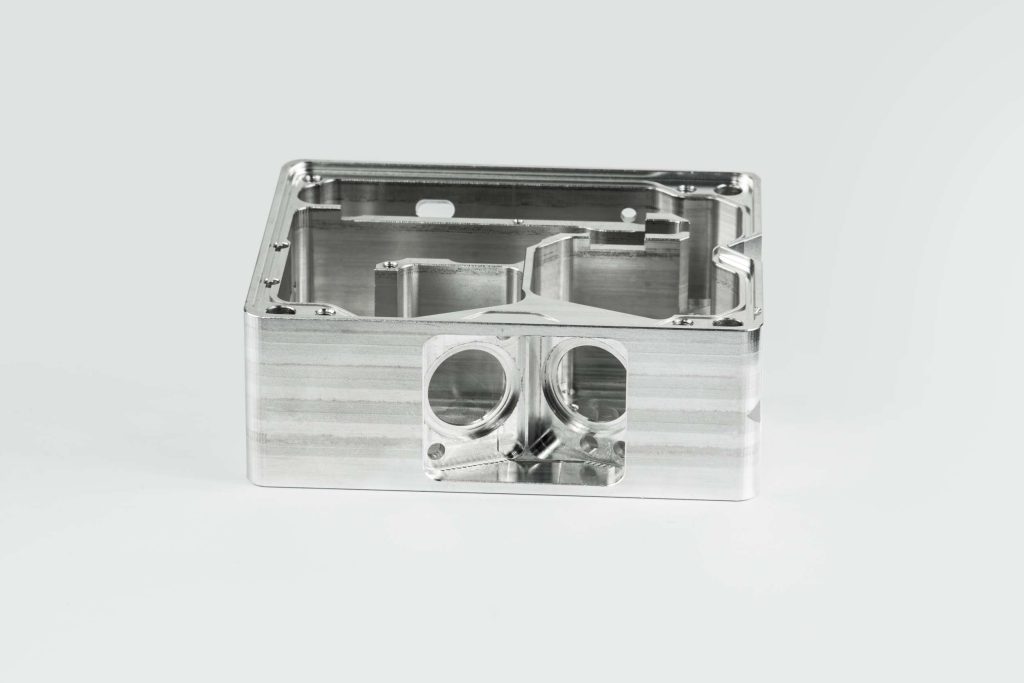

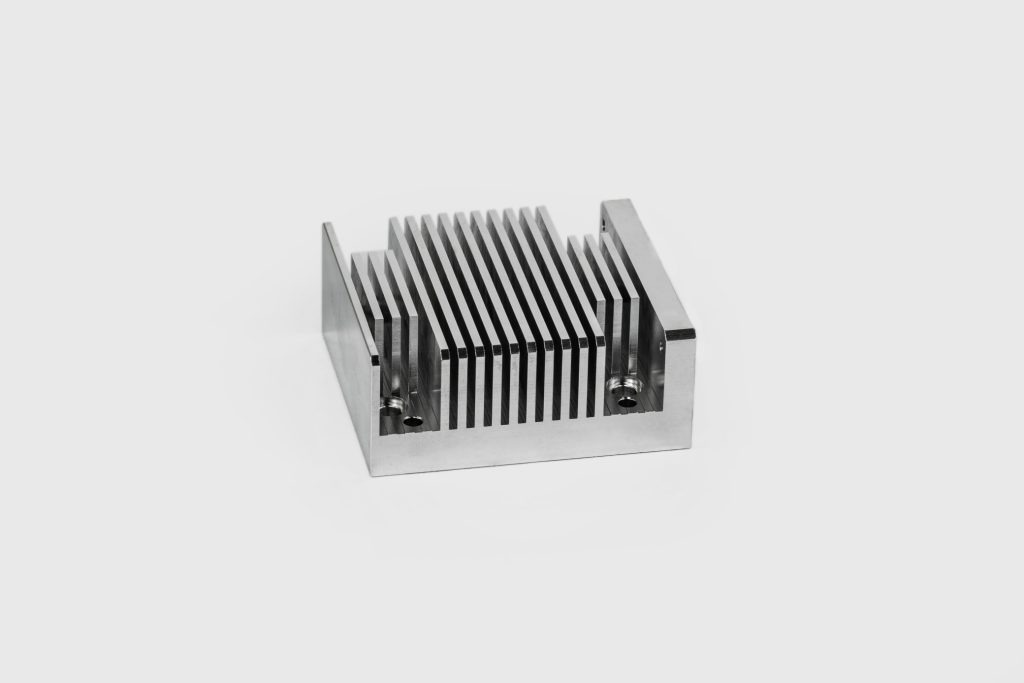

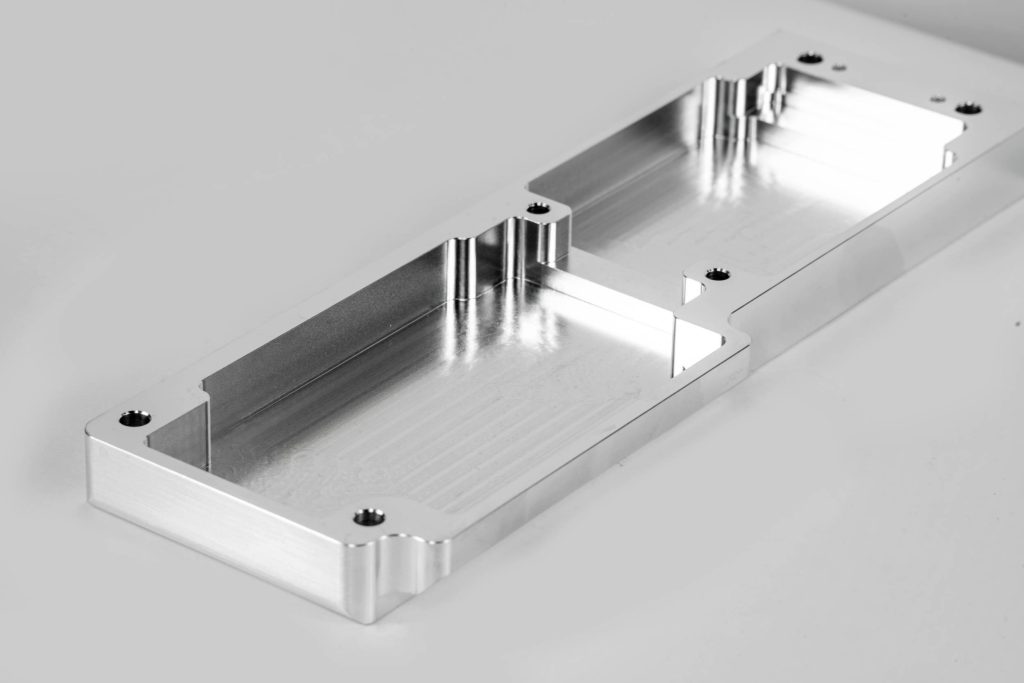

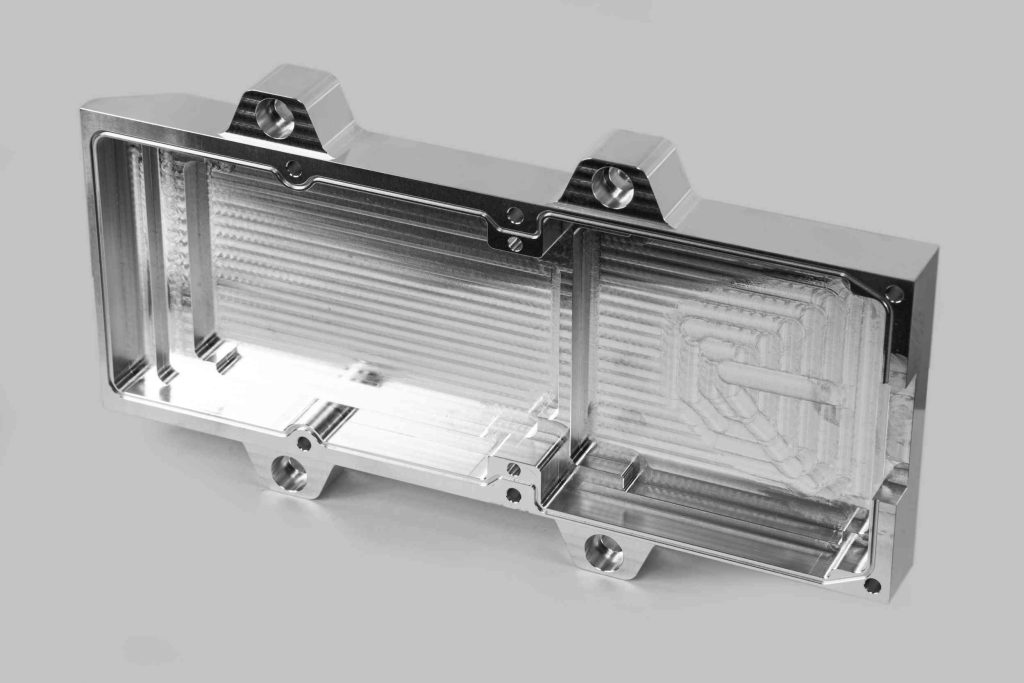

JTR CNC Machining Aluminum Parts

JTR’s CNC Machining Aluminum Capability

| Processes | Lead Time | Tolerance | Price | Applications | Alloys | Finishing Options |

| CNC Mill CNC Lathe | As fast as 3 days | Withdrawing: as low as +/- 0.005 mm No draw: ISO 2768 medium | Fees are determined by product | Lightweight and economical for prototyping to production | 6061, 7075, 7050, 2024, 5052, 6063, MIC6 | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

CNC Machining Materials for Aluminum Parts

Aluminum 2024

2024 aluminum alloy is an aluminum alloy with copper as the main alloying element. It is used in applications requiring a high strength-to-weight ratio as well as good fatigue resistance. Although 2024 aluminum is not as strong as 7075 aluminum, it is often used when a high strength-to-weight ratio is required. It is heat treatable and non-magnetic.

| Density (ρ) | Electrical Conductivity | Young’s Modulus (E) | Elongation (ε) at break | |

| 2.78 g/cm3 (0.1 lb/in3) | 30% | 73 GPa (10.6 Msi) | 10–25% |

Aluminum 6061

The standard alloy used for our machining services is Aluminum 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable.

| Tensile Strength, Yield (MPa) | Young’s Modulus (E) | Density (ρ) | Specific Heat Capacity (c) | Elongation (ε) at break |

| 124–290 MPa (18.0–42.1 ksi) | 68 GPa (9,900 ksi) | 2.70 g/cm3 | 897 J/(kg·K) | 12–25% |

Aluminum 6063

AA 6063 is an aluminum alloy, with magnesium and silicon as the alloying elements. 6063 aluminum is more resistant to corrosion and molding than 6061 aluminum. It is not suitable for high-strength applications but can be used for exterior railings and decorative trim. The benefit of CNC machined 6.63 aluminum is that it is heat treatable and non-magnetic.

| Density (ρ) | Young’s modulus (E) | Tensile Strength (σt) | Elongation (ε) at break | Specific Heat Capacity (c) |

| 2.69 g/cm3 | 68.3 GPa (9,910 ksi) | 145–186 MPa (21.0–27.0 ksi) | 18–33% | 900 J/kg*K |

Aluminum 5052

5052 aluminum is the easiest aluminum to weld and is extremely resistant to salt spray and salt water. It is easy to form, heat treatable, and non-magnetic. The exceptional corrosion resistance of 5052 alloys against seawater and salt spray makes it a primary candidate for the failure-sensitive large marine structures, like tanks of liquefied natural gas tankers.

Typical applications of 5052 aluminum alloy include marine, aircraft, architecture, general sheet metal work, heat exchangers, fuel lines and tanks, flooring panels, streetlights, appliances, rivets, and wire.

| Density (ρ) | Volume Resistivity (ρ) | Young’s Modulus (E) | Elongation (ε) at break | Tensile Strength, Yield (MPa) |

| 2.68 g/cm3 | 49.3-49.9 nOhm*m | 69.3 GPa | 7-27% | 195–290 MPa (28.3–42.1 ksi) |

Aluminum 7075

7075 aluminum is often a hard, high-strength alternative to 6061 aluminum. It is often used for parts in high-stress applications, and 7075 aluminum is also corrosion-resistant, non-magnetic, and heat-treatable.

| Density (ρ) | Young’s modulus (E) | Tensile Strength (σt) | Elongation (ε) at break | Maximum Yield Strength |

| 2.81 g/cc (0.102 lb/cu in) | 71.7 GPa (10,400 ksi) | 572 MPa (83.0 ksi) | 11% | 280 MPa (41 ksi) |

Post Processing of CNC Machined Aluminum Parts

Untreated aluminum usually has a matte silver/grey finish, depending on the roughness of the surface.

Many consumer products made of aluminum need to be anodized, such as laptop computers. Anodizing allows the introduction of various color options and adds a consistent sheen throughout the part.

Aluminum can also be media blasted, sanded, and hand-polished to achieve a variety of surface finishes.

CNC Machining Service With Aluminum – Aluminum Machined Parts in China

In order to meet people’s needs for the diversity and high quality of aluminum alloy shell products, processing skills must be summarized in the processing process. Based on years of CNC machining experience, JTR summarized the machining skills that should be paid attention to in the machining of aluminum alloy shells. JTR is a very professional CNC machining company in China. We provide very exquisite CNC machining aluminum services. The machining machines are equipped with three-axis, four-axis, and five-axis machining centers, drilling and tapping centers, CNC lathes, and more than 10 ordinary machine tools such as lathes, milling machines, drilling machines, and grinders.

Advantages of Our Machining Services

1, Have decades of CNC machining experience, that grounded us to give you perfect solutions to any issues.

2. Have a full inspection and routing inspection during CNC milling aluminum parts production.

3. Has a strong and professional technical team and efficient management operating system and is equipped with advanced manufacturing equipment, ensure you can get the best aluminum parts of CNC machining service.

FAQ