No matter metal or plastic the parts will be, it is necessary to adopt a functional prototype or appearance prototype, and it can be quickly completed by CNC, then make progress of the entire product. And this has made the important position of Aluminum CNC Machining in consumer elections development.

The Irreplaceable Position of CNC Electronics in Consumer Electronics Development

As a typical technology-driven industry, the consumer electronics industry has taken several innovations of industry formation, they come with emerging consumer electronics industry demands. And almost half of the consumer electronics product development cycle was put in the design and the production of enclosure parts, and it is an essential connection between the production and manufacturing of consumer electronics products, its advanced manufacturing technology gets to become one important support for the manufactures of CNC products. With the development of technology, CNC electronics has gained more and more fame.

The innovation of Aluminum CNC Electronics

In recent years, brand-new structural products for new models to speed up the replacement of consumer electronics products are being developed by terminal manufacturers, and one aim of them is the use of aluminum alloy enclosure. Why does it take this long time to take aluminum alloy as a housing electronics product? There are 3 reasons listed to explain this:

- The CNC machining of aluminum housing parts is more complex than other plastic structural parts, what’s more, the cost of material and the processing would be much higher. If aluminum was adopted in structural parts, the price of the whole project would be directed to a higher level. This is the most serious reason why aluminum CNC electronics didn’t get widely used in the housing field early.

2) Although consumers have a diversities of the need of the appearance and color for consumer electronics, it is difficult to color the aluminum housing parts, or to widen the particularity of the physical properties. So the barriers of color diversification and color durability also caused the problems of Aluminum housing parts adoption.

3) It is needed that high radio frequency signal transmission capacity and stability in consumer electronic products, while the shielding characteristics of aluminum enclosure parts are not conducive to the use of consumer electronic products.

Nowadays, science and technology have developed flying fast, the above-mentioned issues have been well-solved. Whether the coloring problem of aluminum housing parts or the problem of radio frequency signal transmission has been handled by hollowing out the backplane and being protected by ceramic materials well.

Application Of CNC On Consumer Electronics From JTR

The case of JTR using CNC to make aluminum consumer electronics enclosure

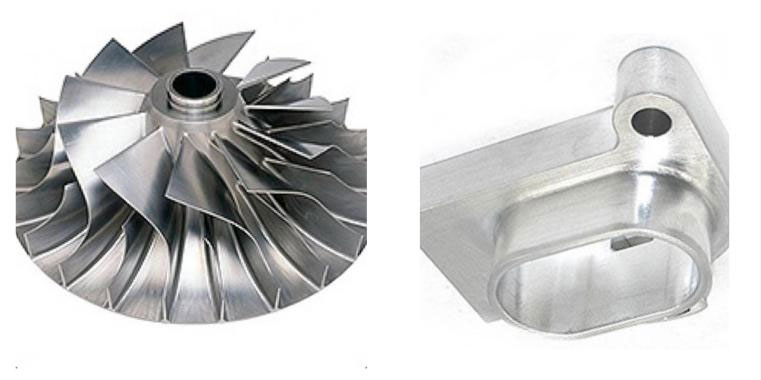

1) The application of CNC in housing parts of consumer electronic products

With the adoption of 6-series aluminum, multi-color anodize, and CNC milling processing, aluminum CNC electronics satisfies the requirements of customers for a diversity of consumer electronics products as well as the need for higher compression resistance. As well as anodizing, we are also able to carry out post-treatment of spray paint on aluminum products, which are in a better level in effect and texture to plastic appearance parts.

2) In addition to housing parts, CNC is also widely used in heat sinks of consumer electronic products

When it mentions heating dissipation, all people would think of copper, while copper is at a much more expensive price and heavier than aluminum to carry, so aluminum becomes more commonly applied in heat dissipation. JTR has helped many customers to accomplish various radiator processing through CNC, and we also gained more experience to become more professional in CNC.

The Advantages Of Aluminum Consumer Electronic Enclosures

The successful application of aluminum shell parts in consumer electronic products has promoted the development of the entire industrial chain of aluminum products, and the numerical control processing technology of consumer electronic products has become increasingly mature. The process and scale of sandblasting and anodizing have also improved significantly. The renewal of consumer demand has also facilitated the derivation of high finishes. Consumer electronic products use aluminum shell parts, with significantly improved compression resistance, bending resistance, heat dissipation effect, scratch resistance and other properties, more fashionable appearance, better texture. That’s why aluminum enclosures have become increasingly popular in recent consumer electronics innovations.

JTR has extensive experience in CNC machining of aluminum housing parts for consumer electronics. As an ISO 9001 certified CNC aluminum plant, JTR’s quality control will be carried out in strict accordance with ISO 9001 quality control system. In addition, we have a technical sales team to provide barrier-free technical communication. If you have similar projects that need our support, you can contact us. We believe that our quality and service will give you a great experience.