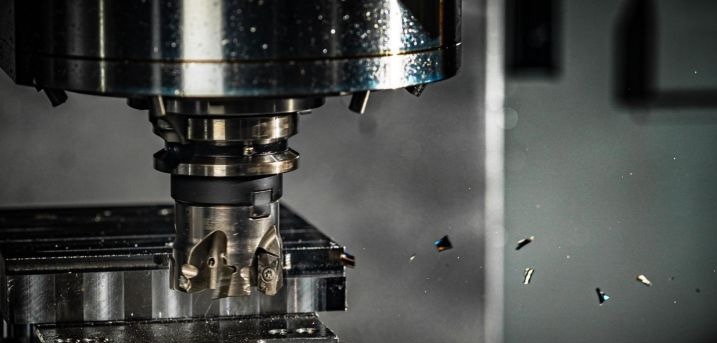

A CNC machine tool is an automatic machine tool equipped with a program control system. CNC machine tools can realize precise, complex, and small batch processing of parts, and are an efficient and flexible automatic machine tool.

There are many types of CNC machine tools, and CNC machine tools can be classified in different ways. These include the way in which the motion is controlled, the type of servo system, the process and use, the function of the numerical control device, and so on.

Classification by Way of Controlling Movement

CNC machine tools can be divided into 3 types: point control, linear control, and contour control according to the way of controlling movement.

1. Point-controlled CNC machine tools

The CNC system only controls the exact position of the tool from one point to another but does not control the motion trajectory. The motion between the coordinate axes is irrelevant, and the workpiece is not processed during the movement. That is to say, only the coordinate position of the tool relative to the positioning point of the workpiece is controlled in the machining plane, and the trajectory of the positioning movement is not required.

This type of control system is mainly used for CNC drilling machines, CNC coordinate boring machines, CNC punching machines, measuring machines, etc.

2. Linear control CNC machine tools

In addition to controlling the exact position between the points, the numerical control system must also ensure that the moving trajectory between the two points is a straight line, and also control the moving speed, also known as point position straight-line control.

Linear control CNC machine tools can control the appropriate feed movement of the tool or workpiece, and perform linear movement and processing in the direction parallel to the coordinate axis. Or control the two coordinate axes to move at the same speed, and perform machining along a 45° oblique line.

This type of control system is mainly used for CNC lathes, CNC boring and milling machines, CNC grinding machines, etc.

3. Contour control CNC machine

The characteristic of contour control is to control the displacement and velocity of two or more moving coordinates simultaneously and continuously. It is not only necessary to control the coordinates of the start and end points of the moving parts of the machine tool, but also to control the speed, direction, and displacement of each point in the entire machining process. For machining complex parts. There are few independent point control and linear control machine tools, and most of them are contour control CNC machine tools. Contour control CNC machine tools can realize linkage processing, as well as point and linear control.

Such CNC machine tools mainly include CNC lathes, CNC milling machines, CNC wire cutting machine tools, and machining centers.

Classification by Servo System Type

CNC machine tools can be divided into open-loop, closed-loop, and semi-closed-loop systems according to the type of servo system. When the servo system controls the movement of the machine tool implement, although the command request value of the numerical control device is accepted, the actual displacement is not necessarily equal to the command request value, that is, there is a certain error.

The main differences between open-loop, closed-loop, and semi-closed-loop systems are the different motors used, whether to perform the measurement of the execution components and error compensation, and the size of the error compensation range.

1. Open loop control

This type of machine tool does not have a position detection feedback device, and usually uses a stepping motor as the actuator. The input data is processed by the numerical control system, and a pulse command is issued to make the stepper motor rotate through a step angle, and then converted into a linear movement of the worktable through a mechanical transmission mechanism. The moving speed and displacement of the moving parts are determined by the input pulse frequency and the number of pulses.

The open-loop system does not carry out the measurement and error compensation of the execution components and has a simple structure, convenient maintenance, relatively low precision, and low cost. It is generally used on small and medium-sized CNC machine tools that do not require high precision.

2. Semi-closed loop control CNC machine tool

A detection element (such as an inductive synchronizer or a photoelectric encoder) is installed at the end of the motor or the end of the lead screw, and the displacement of the moving part is indirectly detected by detecting its rotation angle, and then fed back to the numerical control system. Since most of the mechanical transmission links are not included in the system’s closed-loop loop, relatively stable control characteristics can be obtained. The semi-closed loop system is between the two and only compensates for part of the error, so theoretically its machining accuracy is not as good as the full closed loop system. But debugging is more convenient, so it is widely used.

3. Closed-loop control

This type of CNC machine tool is equipped with a position detection feedback device. The position detection feedback device adopts a linear displacement detection element, which is directly installed on the moving parts of the machine tool, and the measurement results are directly fed back to the CNC device. Feedback can eliminate transmission errors in the entire mechanical transmission chain from the motor to the moving parts of the machine tool, and finally achieve precise positioning.

The closed-loop system has high precision and high cost and is mainly used in large and precision CNC machine tools with high precision requirements.

Classified by Craft Use

CNC machine tools can be divided into general CNC machine tools and CNC machining centers according to their technological uses.

1. General CNC machine tools

Ordinary CNC machine tools generally refer to automated machine tools that realize digital control in a process in the processing process, such as CNC milling machines, CNC lathes, CNC drilling machines, CNC grinding machines, CNC gear processing machine tools, etc. The degree of automation of ordinary CNC machine tools is not perfect, and the replacement of tools and the clamping of parts need to be done manually.

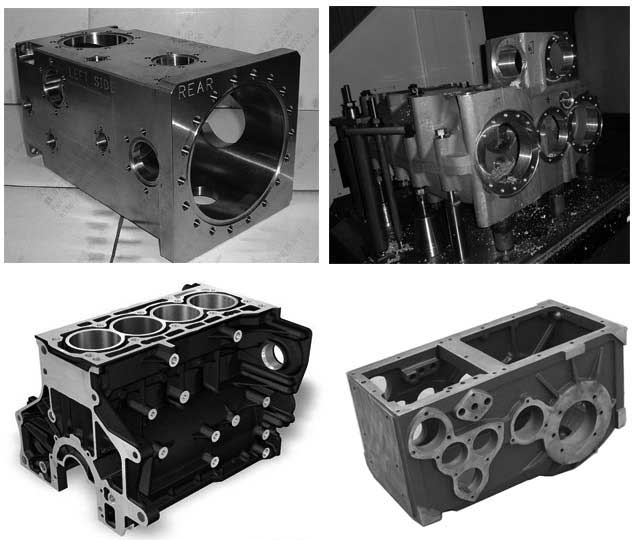

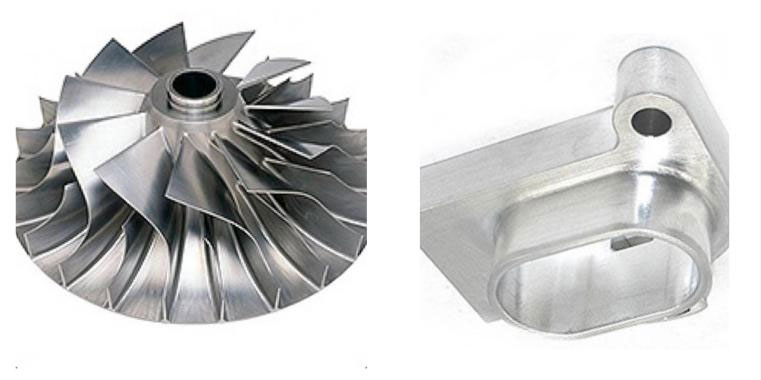

2. CNC machining center

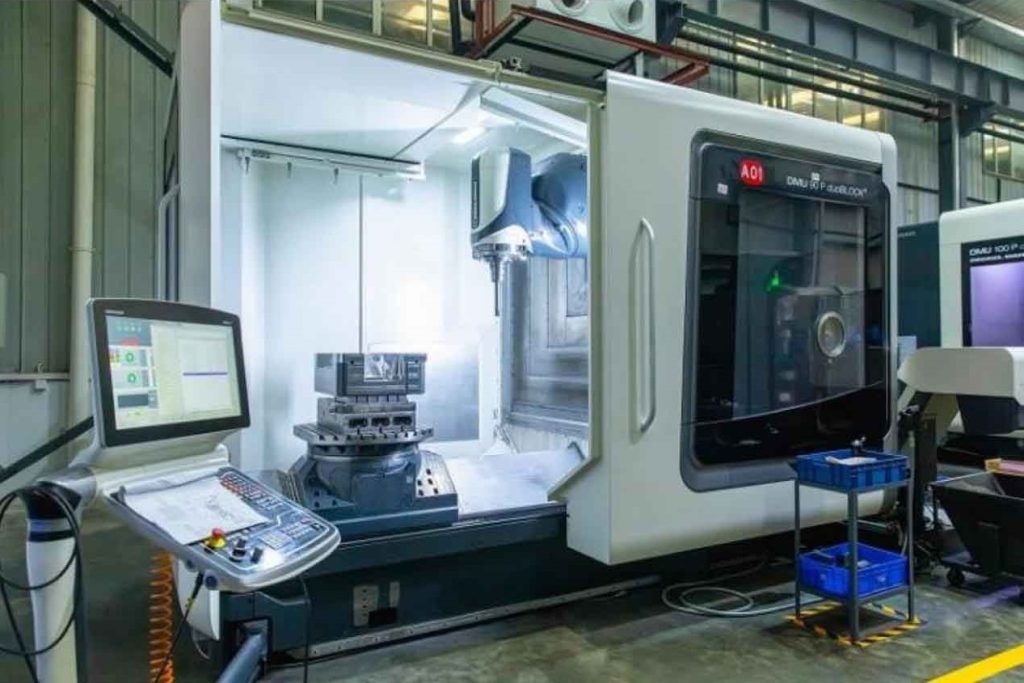

The machining center is a CNC machine tool with a tool magazine and an automatic tool changer. It combines the functions of a CNC milling machine, a CNC boring machine, and a CNC drilling machine. After the parts are clamped once, most of their machining surfaces can be milled.

The most notable feature of the machining center is that it has a tool magazine and a tool-changing manipulator, which can realize multi-process machining.

Classification by Function of the Numerical Control Device

CNC machine tools can be divided into CNC machine tools, simple CNC machine tools, and economical CNC machine tools according to the functions of CNC devices.

The CNC device of CNC machine tool is fully functional and capable of automatic programming, automatic measurement, and automatic fault diagnosis.

Simple CNC machine tools have a single function, only have the basic functions of realizing automation, and adopt an intuitive input method, with a simple structure and low price.

The general-purpose machine tool can be transformed into an economical CNC machine tool by using a single-chip computer and a single-board computer, with reliable performance and easy operation.

Summary

Through the above introduction, we have a basic understanding of the general classification of CNC machine tools. If you want to learn more about CNC machining or make parts related to CNC machining, I hope you can contact JTR at any time. We have the ability and enthusiasm to provide you with quality solutions.