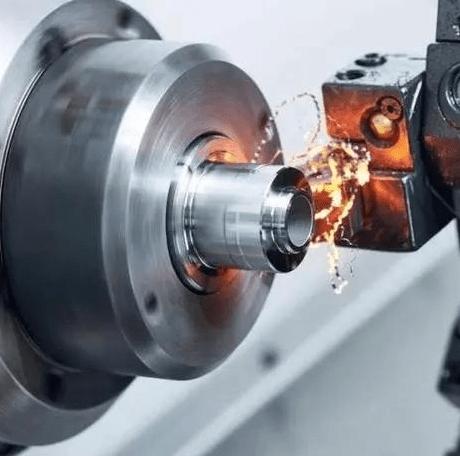

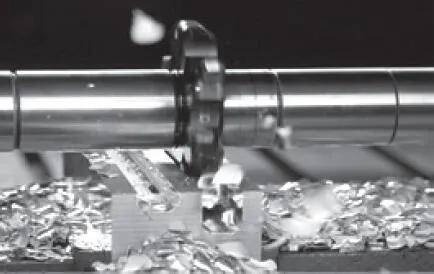

Have you ever wondered how the many parts around us, from the doorknob in your hand to the gears in your car, are made? CNC turning, a precise and automated machining process, is used to shape a wide range of components in many industries. This article delves into the world of CNC turning, looking at the different types of parts it can produce, the various industries it serves, and the reasons for its widespread use.

What Parts Could be CNC Turning?(3 Aspects)

1. Part Geometry

- Symmetrical: This category emphasizes the overall shape of the part. CNC turning is ideal for producing parts with rotational symmetry, which means they appear the same when rotated around a central axis. Examples include shafts, bushings, and gears.

- Cylindrical or Round: This category describes the part’s cross-sectional shape. CNC turning is particularly good at producing parts with cylindrical or round cross-sections because the cutting tool travels in a circular path around the workpiece. Examples include bearings, knobs, and flanges.

- Complexity: This category considers the part’s intricate features and details. CNC turning can produce simple cylindrical parts, but it excels at creating more complex geometries with internal cavities, threads, undercuts, and varying angles.

2. Material and Production Characteristics

- Can Be Produced from Bar or Tube Stock: This category highlights the starting material used in CNC turning. The process usually starts with a solid bar or tube of material, which is then machined to the desired shape. This makes it appropriate for parts with generally round cross-sections.

- Materials: This category encompasses the various materials that can be used in CNC turning. It contains metals such as steel, aluminum, and brass, as well as plastics and wood. The material used is determined by the specific strength, weight, and functionality requirements of the part.

3. Production Considerations

- Production Volume: This category assesses the suitability of CNC turning for various production volumes. CNC turning is useful for both small batches (prototypes) and large-scale manufacturing because of its precision, repeatability, and ability to reduce material waste.

In essence, these categories provide a comprehensive framework for understanding the types of parts that can be efficiently produced using CNC turning. CNC turning is a versatile and valuable manufacturing process for a variety of applications due to its combination of part geometry, material compatibility, and production considerations.

CNC Turning Parts in Various Industries

CNC Turning Parts in Various Industries

| Industry | Example Parts | Description |

| Automotive | Engine components (pistons, valves, camshafts) Transmission parts (gears, shafts) Suspension components (tie rods, ball joints) | CNC turning is crucial for high-precision, symmetrical parts that can handle stress and heat. |

| Aerospace | Landing gear components (struts, shafts) Engine parts (turbine blades, housings) Hydraulic components (pistons, cylinders) | Strict tolerances and weight reduction are key in aerospace. CNC turning delivers precise, lightweight parts. |

| Medical Devices | Surgical instruments (scalpel handles, forceps) Prosthetic components (joint implants) Dental implants | Biocompatible materials and smooth finishes are vital. CNC turning ensures accuracy and sterility. |

| Consumer Electronics | Knobs and dials for electronics Heat sinks for cooling Housings for small devices | CNC turning creates parts with a balance of aesthetics, functionality, and affordability. |

| Oil & Gas | Drill bits and cutting tools Valve components (stems, seats) Pump shafts and gears | Durability and resistance to harsh environments are essential. CNC turning provides strong, reliable parts. |

| Firearms | Barrels and receivers Trigger components (pins, sears) Scopes and sights (adjusting mechanisms) | Strict safety regulations necessitate precise parts. CNC turning ensures consistent dimensions and functionality. |

| Furniture Hardware | Door knobs and handles Furniture legs and supports Decorative elements | CNC turning offers a balance of aesthetics, strength, and cost-effectiveness for furniture parts. |

Note: This table gives a general overview. CNC turning produces a much broader range of parts within each industry.

What Are the Main Types of Parts That CNC Turning Can Create?

1. Shafts and Axles

- Function: These are cylindrical rods that transfer rotational power or support rotating components. They frequently include machined features such as shoulders, grooves, and keyways for connecting gears, bearings, and other components.

- Applications: Shafts are used in a variety of applications, ranging from simple doorknobs to complex machinery. Examples include crankshafts in engines, axles in automobiles and bicycles, and stirring rods in mixers.

2. Bushings and Bearings

- Function: These components reduce the friction between moving parts. Bushings are simple sleeves, whereas bearings use rolling elements (balls or rollers) to reduce friction. Both can be made using CNC turning.

- Applications: Bushings and bearings are essential for machinery with moving parts. Examples include hinge bushings and bearings in gearboxes and electric motors.

3. Knobs and Handles

- Function: These are manual controls for various equipment and tools. They can range from simple gripping knobs to more complex handles with levers or integrated buttons.

- Applications: Knobs and handles are used in a wide range of applications, including furniture and appliances, industrial machinery, and medical devices.

4. Gears and Sprockets

- Function: These toothed wheels work together to transfer power and change the rotational speed or direction. Gears are usually enclosed, whereas sprockets have exposed teeth that connect with chains.

- Applications: Gears and sprockets are essential components in power transmission systems. Examples include transmission gears, bicycle sprockets, and engine timing gears.

5. Pins and Dowel Pins

- Function: These are cylindrical rods used to position and align other parts. They can be straight or tapered, and are frequently press-fitted into pre-drilled holes.

- Applications: Pins and dowel pins are required for the precise assembly of components. Alignment pins in furniture, dowel pins for wood joining, and roll pins for shaft securing are some examples.

6. Fasteners: Nuts, Bolts, and Screws

- Function: These threaded components are used to securely connect parts. CNC turning produces the precise threads and head shapes required for various fasteners.

- Applications: Fasteners are essential components of any mechanical assembly. They are used in a variety of applications, including furniture, appliances, bridges, and buildings.

7. Flanges and Couplings

- Function: These parts join pipes, tubes, or shafts together. Flanges are typically flat plates with bolt holes, whereas couplings can be clamped or welded into place.

- Applications: Flanges and couplings are used in numerous applications to create fluid and power transmission systems. Examples include pipe flanges in plumbing systems, shaft couplings in machinery, and hose couplings used to connect hoses.

8. Rings and Seals

- Function: These components ensure a tight fit between mating surfaces, preventing leaks. Rings can be simple or complex in order to form a good seal.

- Applications: Rings and seals prevent leaks in fluid systems. Examples include piston rings in engines, O-rings for valve sealing, and gaskets for creating a tight seal between engine components.

Conclusion

CNC turning, with its ability to produce high-precision, symmetrical parts from a wide range of materials, is a cornerstone of modern manufacturing. CNC turning has a wide range of applications, from intricate components in medical devices to robust parts in heavy machinery. As technology advances, the capabilities of CNC turning are likely to expand even further, shaping the future of numerous industries. Understanding the different types of parts it can make and their applications in various industries provides valuable insight into the power and versatility of this remarkable manufacturing process. JTR as a professional company will give you the first-class CNC turning service.