Mold making is a critical step in manufacturing, influencing production speed, cost, and overall product quality. But how long does it take to make a mold? The answer depends on mold complexity, material, manufacturing process, and customization requirements.

In this article, we will break down mold-making lead times from different perspectives and introduce Chongqing Jin Te Rui Machine Co., Ltd., a trusted manufacturer specializing in rapid prototyping and mass manufacturing services, including CNC machining, die casting, 3D printing, rapid tooling, injection molding, and sheet metal prototyping.

Factors Affecting Mold Making Lead Time

The time required for mold making varies widely based on several key factors:

| Factor | Impact on Lead Time |

| Mold Complexity | More intricate designs require longer machining and testing. |

| Mold Size & Material | Large and hard metal molds take more time to produce. |

| Manufacturing Method | CNC machining, EDM, and 3D printing have different speeds. |

| Customization Level | Highly customized molds need additional design and testing. |

| Tooling & Finishing | Post-processing like polishing and heat treatment adds time. |

| Production Volume | High-volume molds may require additional optimization. |

Typical Lead Times for Different Mold MakingTypes

| Mold Type | Lead Time |

| Prototype Mold (Soft Tooling, 3D Printed) | 1 – 2 weeks |

| Simple Aluminum Mold | 2 – 4 weeks |

| Injection Molding Tool (Single Cavity) | 4 – 6 weeks |

| Complex Multi-Cavity Mold | 6 – 12 weeks |

| Die Casting Mold (Zinc/Aluminum) | 6 – 10 weeks |

| Large Automotive Mold | 10 – 16+ weeks |

Each mold type requires different materials and production processes, affecting overall manufacturing speed.

Step-by-Step Mold-Making Process & Time Breakdown

| Stage | Process | Estimated Time |

| 1. Design & Engineering | CAD modeling, DFM analysis | 1 – 2 weeks |

| 2. Material Selection | Choosing steel, aluminum, etc. | 1 – 3 days |

| 3. CNC Machining & EDM | Creating core and cavity | 2 – 6 weeks |

| 4. Heat Treatment | Hardening for durability | 1 – 2 weeks |

| 5. Polishing & Finishing | Surface treatment & texturing | 1 – 2 weeks |

| 6. Assembly & Testing | Mold trial & adjustments | 1 – 3 weeks |

Total lead time depends on complexity, size, and manufacturing conditions.

How to Reduce Mold Lead Time?

For businesses looking to speed up mold production, consider these strategies:

Optimize Design for Manufacturability (DFM)

✔ Simplify part geometry to reduce machining time.

✔ Minimize undercuts and sharp corners to avoid complex tooling.

Choose the Right Mold Material

✔ Aluminum molds are faster to machine than steel molds.

✔ Soft tooling (urethane or plastic) is ideal for prototyping.

Leverage Advanced Manufacturing Technologies

✔ 3D printing speeds up prototype mold production.

✔ High-speed CNC machining reduces lead time.

✔ Electrical Discharge Machining (EDM) improves precision for complex parts.

Partner with a Reliable Manufacturer

Working with an experienced mold maker ensures faster turnaround without quality compromises.

Final Thoughts: How Long Does Mold Making Take?

Mold lead time varies based on design complexity, material, and manufacturing process. Prototype molds can be ready in 1–2 weeks, while high-precision production molds may take 6–12 weeks or more.

Product design and development in both 2D and 3D formats

JTR Machine’s product design services are mainly aimed at optimization. While we can also deal with all technical aspects of creating prototypes and parts. After 10 years of engagement in the industry, we’ve added new technologies in the whole process of product design and production, meeting the requirements of our customers and reducing the cost.

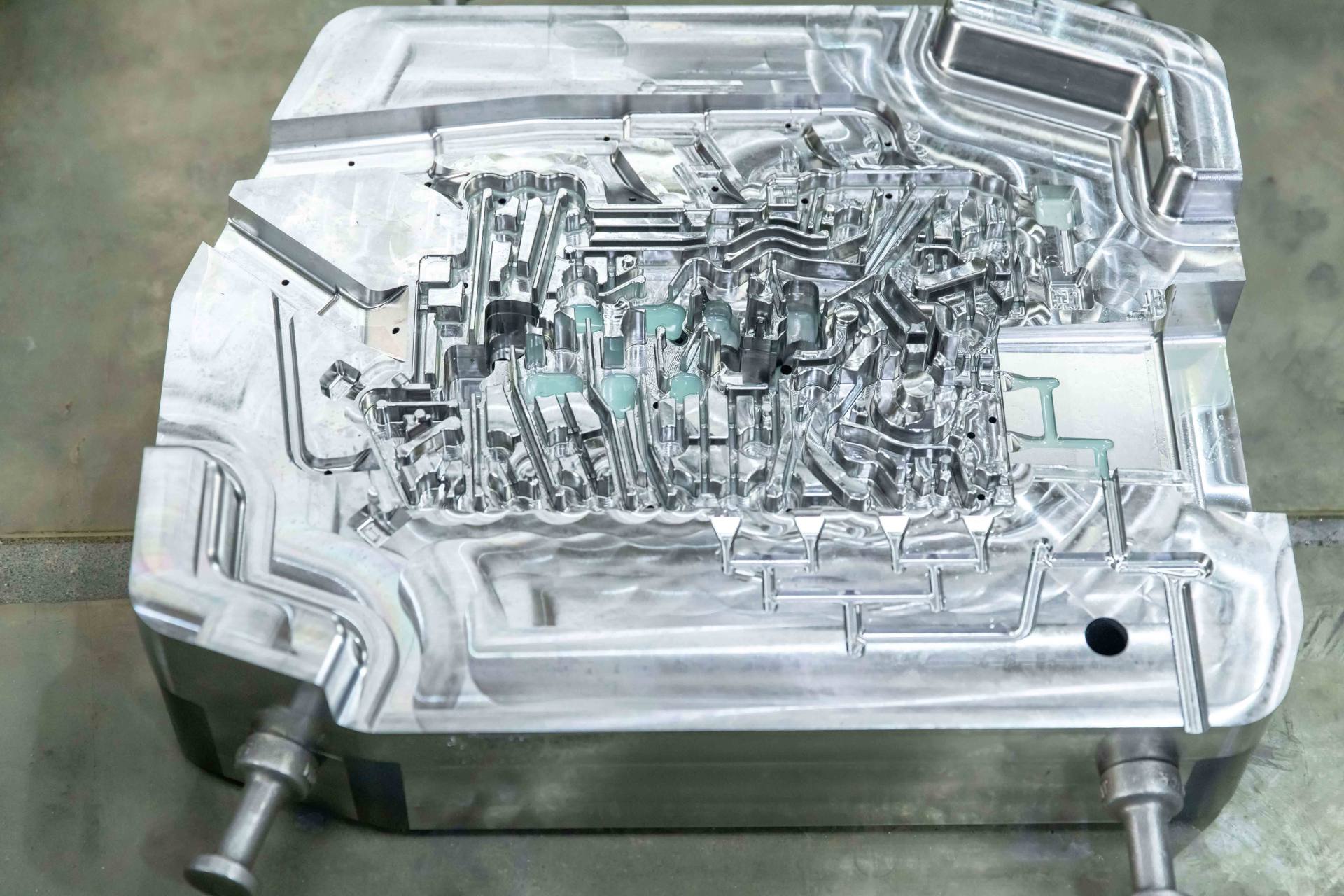

Mold making/Prototyping/Tooling

As a high-quality mold manufacturer in western China, JTR Machine’s mold-making partners can quickly make die-casting molds, injection molds, gravity casting molds, etc. Whether you need a prototype mold for short-term production or a mold for millions of batches, we can provide them with high quality and in a short lead time.