3D printing is additive manufacturing. Based on digital model files, 3D objects are constructed by layer-by-layer printing using bondable materials such as powdered metal or plastic. It has clear advantages such as product diversification and material saving. There are many types of 3D printing, of which SLA and SLS are two of the more common types. This article will analyze the difference between these two 3D printing from multiple perspectives.

First of all, what is the difference between the concept of SLA and SLS 3D printing?

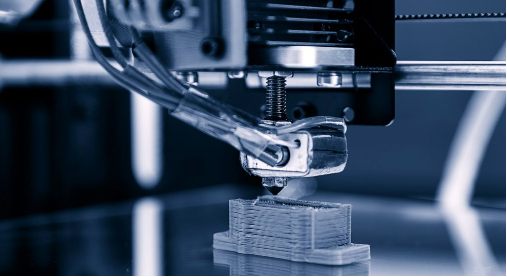

SLA 3D printing focuses the ultraviolet laser with a specific wavelength and intensity on the surface of liquid photosensitive resin material so that it is solidified from point to line and from line to surface to complete the printing operation of one layer. And then the lifting platform moves one layer in the vertical direction height and then solidifies another level. In this way, layers are superimposed to form a three-dimensional entity.

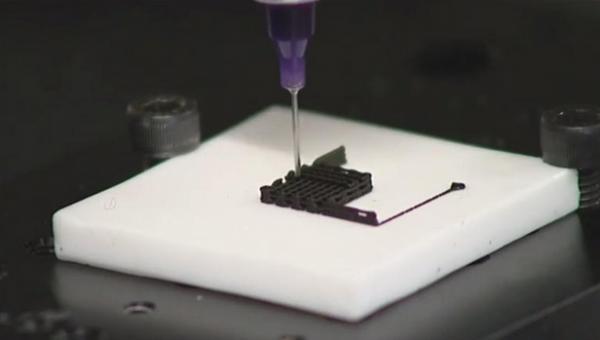

SLS 3D printing is powder sintering at high temperatures with the help of the infrared laser. The laser beam is controlled to scan the powder layer of the cross-sectional profile of the layer so that the temperature of the powder is raised to the melting point for sintering and bonding with the formed part below. When a section of a layer is sintered, the table is moved by the thickness of one layer, and the process is repeated until the entire 3D model is completed.

What is the difference between SLA and SLS printing materials?

SLA 3D printed material: liquid photopolymer

Materials for SLS 3D printing: Nylon powder, acrylic polymer powder, and a mixture of ceramics or metals and binders are used.

What is the difference between the resolution of SLA and SLS printing?

SLS and SLA printers use completely different wavelengths, with SLA printing using ultraviolet light and SLS printing using infrared light. The areas of concentrated irradiation of ultraviolet light and infrared light are different, and the light area of ultraviolet light is much smaller than that of infrared light. Therefore, SLA printers usually have higher resolutions.

What is the difference between SLA and SLS printed products?

The finished product of SLA 3D printing:

- The surface is relatively smooth and does not need to be polished after printing.

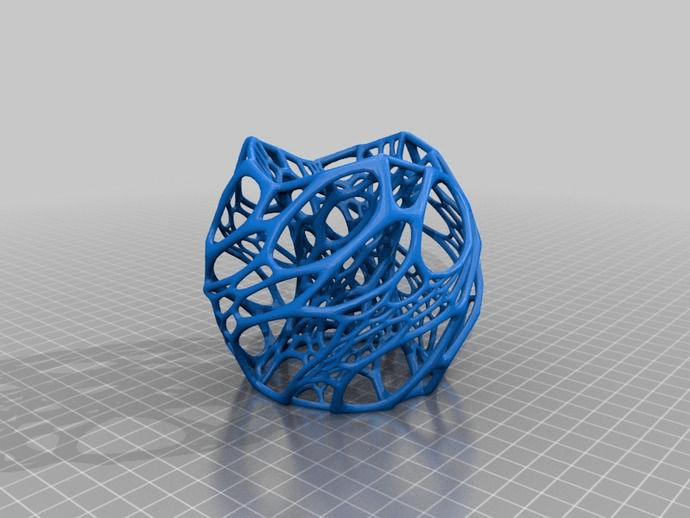

- Capable of making finer, intricately detailed parts.

- Molded parts need to be post-cured.

The finished product of SLS 3D printing:

- The surface is relatively loose and rough.

- Higher shrinkage, suitable for large industrial prototypes with mechanical and functional features.

- With good mechanical properties, the thermoplastic materials used in SLS are relatively easy to process and can be easily milled, drilled, and tapped.

- The unsintered powder can be reused, and the utilization rate of the material is high.

- The bond strength of SLS is better than that of SLA because the material surface of SLS has many voids to facilitate the penetration of adhesive.

What is the difference between SLA and SLS printing support structures?

For almost all 3D printing technologies, if the printed object does not have obvious support points, it needs to have a support structure.

SLS printing does not require support structures because the unsintered powder acts as a support material during the printing process.

However, SLA printers require a support structure.

The above introduces the difference between SLA 3D printing and SLS 3D printing. In addition to these two printing methods, there are FDM, MJF, and so on. In the follow-up content, we will continue to introduce the connection and difference between them.

Summarize

JTR is an excellent manufacturer of 3D printing products in China, we can provide excellent 3D printing services, including FDM, SLS, SLA, Carbon DLS, DMLS, MJF, and PolyJet 3D printing. If you have drawings and need 3D printing services, please contact us! We will provide you with the best price and product.