3D printing is additive manufacturing. It first uses computer modeling software to model, uses adhesive materials such as plastic or powdered metal, “partitions” the built 3D model into layer-by-layer sections, and constructs 3D objects by layer-by-layer printing. 3D printing Common 3D printing technologies include SLA 3D printing, FDM 3D printing, SLS 3D printing, etc. We often encounter people asking about the difference between SLA printing and FDM printing. This article will introduce the difference between these two 3D printing methods in detail.

Different Principles Between FDM 3D Printing and SLA 3D Printing

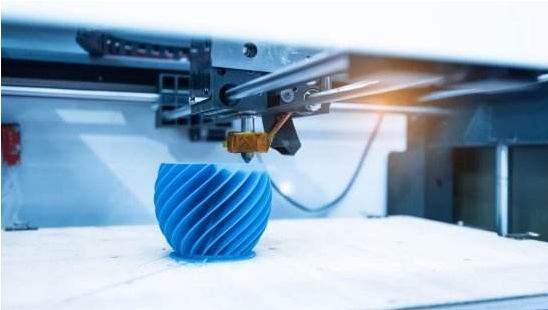

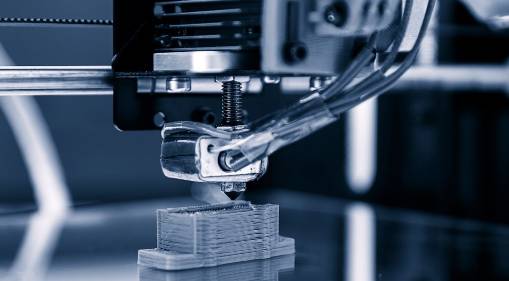

- FDM 3D printing stands for Fused Deposition Modeling, which is a method of processing that does not use lasers.

The principle of FDM is:

Various hot-melt filamentous materials (wax, ABS and nylon, etc.) are heated and melted to form, and the computer controls the nozzle to perform x-y linkage and z-direction movement. The filamentous materials are heated to a temperature just above their melting point in the nozzle and extruded through a nozzle with a tiny nozzle.

- SLA 3D printing is the abbreviation of “Stereo lithography Appearance”, which refers to the stereolithography method.

The principle of SLA is:

Use a laser with a specific wavelength and intensity to focus on the surface of the light-curing material, solidify from point to line, and from line to the surface to complete the printing of one layer, and then move the lifting platform in the vertical direction to the height of one layer, and then cure the next layer. This is repeated layer by layer until the finished product is printed.

Different Accuracy Between SLA 3D Printing and FDM 3D Printing

Printing accuracy of FDM:

FDM is to obtain parts by extruding molten materials layer by layer through a nozzle, and the finished product will have a relatively obvious surface texture, and the precision is not very high.

This is due to the lower adhesion between layers than SLA printing, and the weight of the upper layer may squeeze the layer below, so many printing problems may occur (for example, warping, layer misalignment, layer shifting, lower part shrinkage ). These compromise precision and surface smoothness. In addition, in theory, the smaller the diameter of the nozzle of the FDM model, the higher the accuracy, but the nozzle is small, and it is easy to cause clogging of consumables. So it’s not that the smaller the nozzle, the better.

Printing accuracy of SLA:

SLA produces higher-resolution objects with greater precision. The photosensitive resin material has a smooth surface quality and is easy to post-process, and can be used to produce various precision parts and assemblies with complex structures.

Different Materials Between SLA 3D Printing and FDM 3D Printing

FDM printing materials:

FDM printing materials mainly include PLA, ABS, TPE, TPU, and other plastic filaments. Most FDM printers can handle nylon, PVA, TPU, and several PLA blends (mixed with wood, ceramic, metal, carbon fiber, etc.). Plastic filaments are available in a variety of colors and are relatively inexpensive.

SLA printing materials:

The printing material of SLA is photosensitive resin material. Color choices are also more limited, but more durable or highly specialized materials are available for industrial use.

How to Choose FDM 3D printing or SLA 3d printing?

Choose FDM:

Build low-cost models.

Great for hobbyists and makers.

When precision and surface roughness are not critical.

Choose SLA:

When intricate details and a smooth surface finish are critical.

Used when making casting molds to facilitate mass production.

When the strength and durability of the model are not critical (models made of resin may be damaged by prolonged exposure to sunlight).

JTR can provide a variety of 3D printing services, including SLA, SLS, FDM, etc. If you want to know the difference between these 3D printing, you can check out more articles about JTR. If you have drawings and want to 3D print products directly, please contact JTR, we will be happy to provide you with professional printing services.