Casting is a fundamental manufacturing process used to create complex metal parts by pouring molten metal into a mold. Sand casting and die casting are two of the most common methods, each with distinct advantages, applications, and cost implications.

In this article, we will explore the key differences between sand casting and die casting from various perspectives and introduce Chongqing Jin Te Rui Machine Co., Ltd., a leading manufacturer specializing in high-quality rapid prototyping and mass manufacturing services.

Key Differences Between Sand Casting and Die Casting

| Aspect | Sand Casting | Die Casting |

| Mold Material | Sand-based, temporary mold | Metal-based, permanent mold |

| Production Speed | Slower, more manual process | High-speed, automated process |

| Surface Finish | Rougher texture, requires post-processing | Smooth, precise, minimal finishing needed |

| Complexity & Detail | Suitable for large, simple parts | Ideal for small, intricate parts |

| Cost Efficiency | Lower initial cost, higher per-unit cost | Higher initial cost, lower per-unit cost in mass production |

| Material Compatibility | Works with ferrous and non-ferrous metals | Best for non-ferrous metals (aluminum, zinc, magnesium) |

| Durability of Mold | Single-use (needs new mold for each casting) | Reusable, long-lasting metal mold |

| Size & Weight | Can produce large, heavy parts | Best for small to medium-sized components |

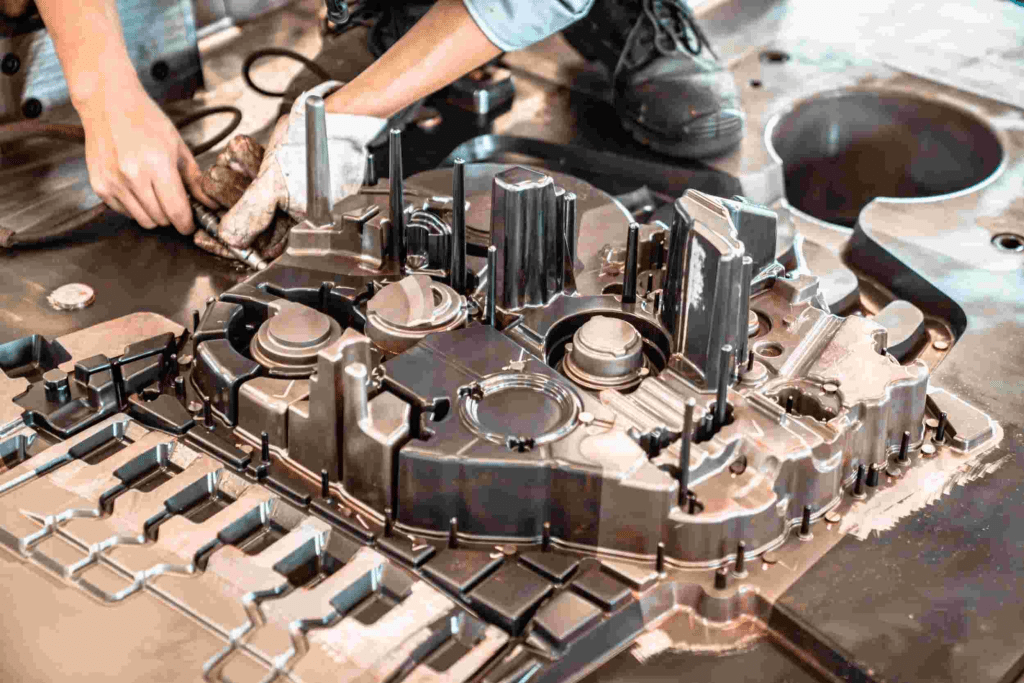

What Is Sand Casting?

✅ Process Overview

- A pattern (replica of the final part) is created.

- The pattern is placed inside a sand mold, which is packed tightly.

- Molten metal is poured into the mold cavity.

- After solidification, the sand mold is broken apart to retrieve the cast part.

Advantages of Sand Casting

✔ Low initial cost – Ideal for small production runs.

✔ Handles large parts – Can create components weighing several tons.

✔ Versatile material use – Suitable for iron, steel, aluminum, bronze, and brass.

Limitations of Sand Casting

❌ Lower precision – More post-processing is required for a smooth surface.

❌ Slower production time – Each casting requires a new mold.

Common Applications of Sand Casting

- Engine blocks

- Large machine parts

- Industrial equipment

- Heavy construction components

What Is Die Casting?

✅ Process Overview

- A permanent metal mold (die) is created.

- Molten metal is injected into the die under high pressure.

- The metal solidifies rapidly, and the part is ejected from the mold.

- Minimal finishing is required before final use.

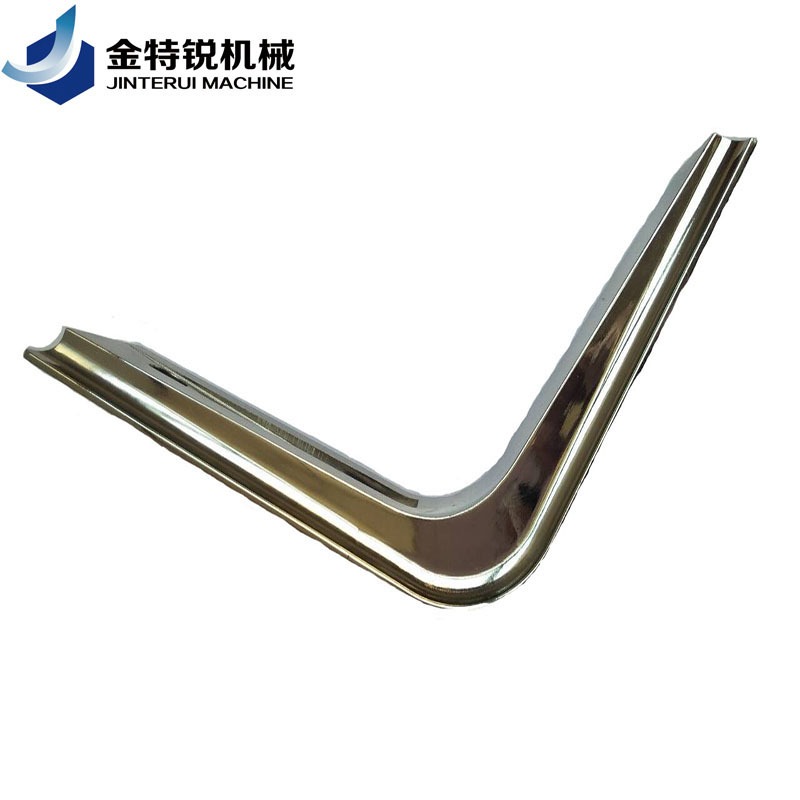

Advantages of Die Casting

✔ High precision – Produces parts with excellent detail and tight tolerances.

✔ Fast production speed – Ideal for high-volume manufacturing.

✔ Smooth surface finish – Reduces the need for post-processing.

Limitations of Die Casting

❌ Higher initial cost – Metal molds are expensive to manufacture.

❌ Limited material choices – Best for non-ferrous metals like aluminum, zinc, and magnesium.

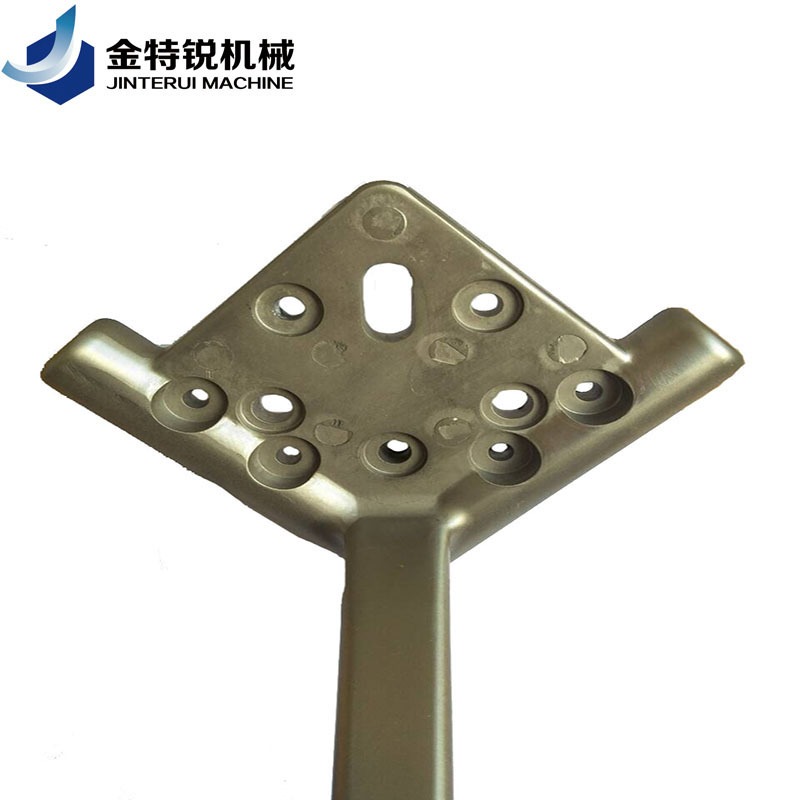

Common Applications of Die Casting

- Automotive parts (gear housings, engine components)

- Consumer electronics (phone frames, laptop casings)

- Aerospace components

- Precision industrial equipment

Cost Comparison: Which Casting Method Is More Economical?

| Cost Factor | Sand Casting | Die Casting |

| Mold Cost | Low | High |

| Per-Unit Cost | Higher | Lower (in mass production) |

| Labor Intensity | More manual | More automated |

| Production Time | Longer | Shorter (rapid cooling & solidification) |

| Material Wastage | More waste | Less waste |

Best Choice Based on Production Scale

✔ For small-batch production → Sand Casting is more cost-effective.

✔ For mass production → Die Casting is the preferred choice due to its efficiency and precision.

Why Choose Chongqing Jin Te Rui Machine Co., Ltd.?

If you need high-quality sand casting or die casting services, Chongqing Jin Te Rui Machine Co., Ltd. is the go-to expert for:

✅ Rapid prototyping & mass manufacturing – Fast turnaround for prototypes and large-scale production.

✅ Advanced die casting technology – Producing precise, durable components for various industries.

✅ Diverse manufacturing services – CNC machining, 3D printing, injection molding, sheet metal prototyping, and more.

✅ Custom product development – From design to production, offering tailored solutions.

Chongqing Jin Te Rui Machine Co., Ltd. specializes in aluminum extrusion, plastic molding, and metal fabrication, ensuring top-tier quality and cost efficiency for your business needs.

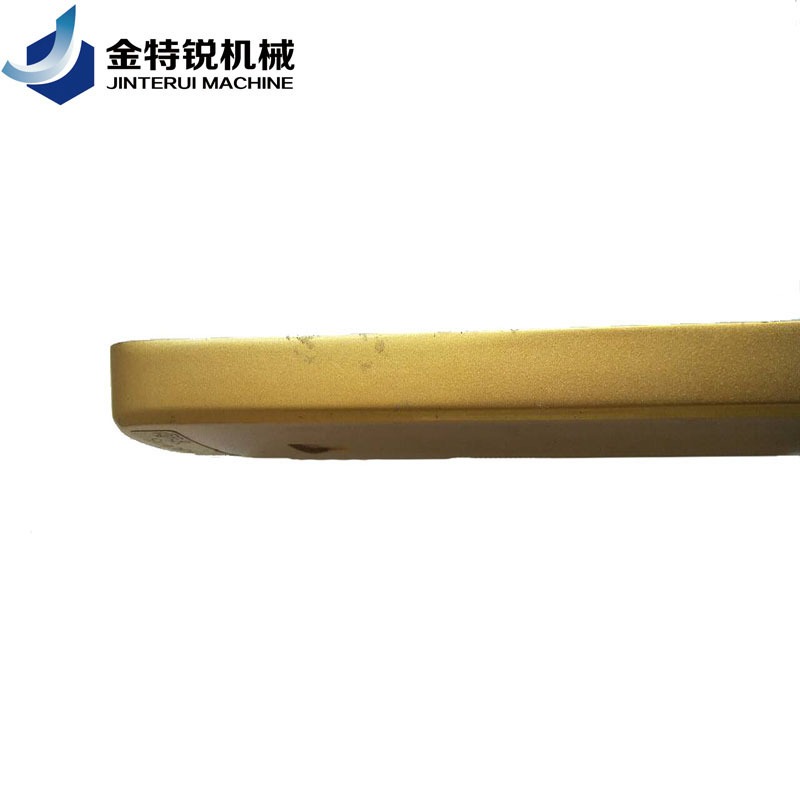

Zamak stainless steel die casting parts

Customized Zamak die casting parts

Custom polished Zamak die casting parts

Die casting aluminum parts

Die casting and CNC machining motor parts

CNC milling and die casting car parts

Conclusion: Which Casting Method Is Right for You?

The choice between sand casting and die casting depends on your budget, production volume, and material requirements.

Choose Sand Casting if

✔ You need large, low-volume parts.

✔ You work with ferrous metals (iron, steel).

✔ You want lower mold costs and can accommodate a longer production time.

Choose Die Casting if

✔ You need high-precision, mass-produced parts.

✔ You work with non-ferrous metals (aluminum, zinc, magnesium).

✔ You require fast production and minimal post-processing.

Need professional casting services? Contact Chongqing Jin Te Rui Machine Co., Ltd. today for top-notch prototyping and manufacturing solutions!