As a professional mechanical engineer, you may have heard of CNC machining, CNC milling, CNC turning. So has anyone asked you what NC is? What is the relationship between CNC machining and NC? What’s the difference between them? This article will answer the difference between CNC and NC from the simple and easy-to-understand text.

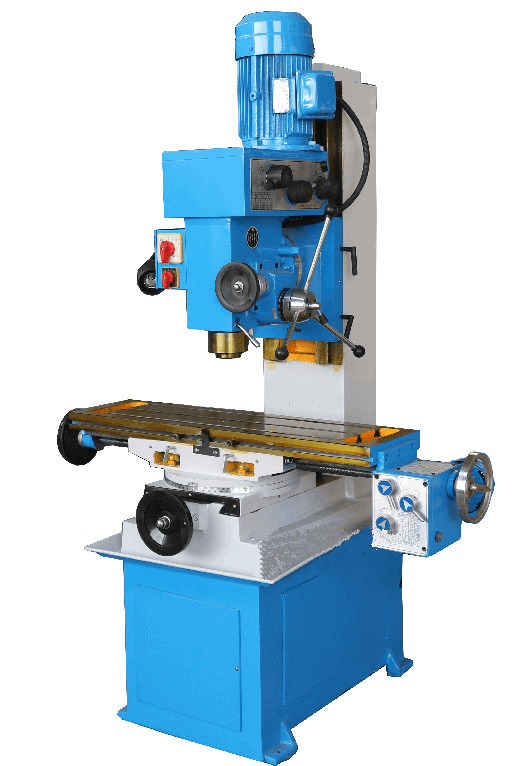

What is NC?

NC (Numerical Control) refers to the use of discrete digital information to control the operation of machinery and other devices, which can only be programmed by the operator.

What is CNC?

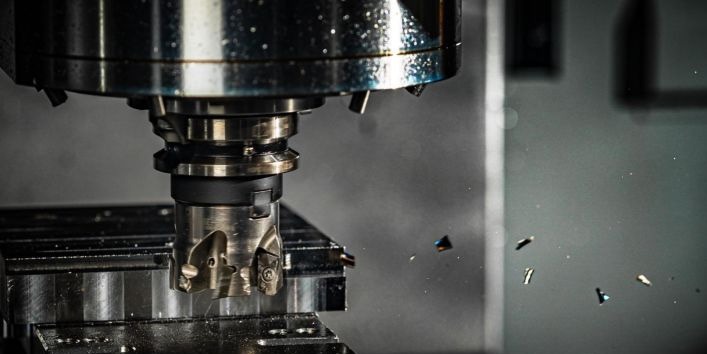

Since its invention, CNC has been widely used in product manufacturing, model manufacturing, and other fields. Although new technologies such as additive manufacturing have emerged now, CNC machining, as the most mature technology, the most efficient and the most stable processing method for product quality, has always been the mainstream processing method in the processing and manufacturing industry. First, you need to know what CNC technology is.

The development of CNC technology has been quite rapid in recent years, which has greatly improved the productivity of mold processing. Among them, the CPU with faster operation speed is the core of the development of CNC technology. The improvement of the CPU is not only the improvement of operation speed, but the speed itself also involves the improvement of CNC technology in other aspects. It is precise because CNC technology has undergone such great changes in recent years. It is worth reviewing the current application of CNC technology in mold manufacturing.

Block processing time, and the performance of CNC has improved significantly due to the increased processing speed of CPU and the adoption of high-speed CPU by CNC manufacturers into highly integrated CNC systems. A more responsive system achieves more than just a higher program processing speed. In fact, a system that can process part programs at a relatively high speed may also operate as a low-speed system because even a fully functional CNC system has potential problems that can become limiting the bottleneck of processing speed.

Today, most mold shops realize that high-speed machining requires more than just shorter program processing times. In many ways, the situation is similar to driving a racing car. Does the fastest car always win the race? Even an occasional spectator of a car race knows that many factors other than speed affect the outcome of a race.

First of all, the driver’s knowledge of the track is important: he must know where there are sharp turns to decelerate appropriately to get through the corners safely and efficiently. In the process of machining molds with a high feed rate, the tracking technology to be machined in the CNC can obtain information about the appearance of sharp curves in advance, and this function plays the same role.

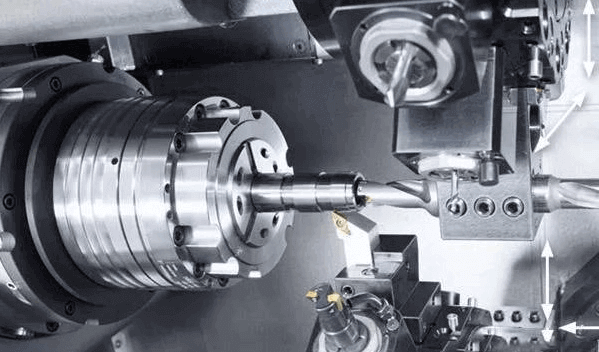

Likewise, the driver’s responsiveness to other driver actions and uncertainties is similar to the amount of servo feedback in a CNC. Servo feedback in CNC mainly includes position feedback, speed feedback, and current feedback.

When a driver is driving around the track, the continuity of the action and whether he can brake and accelerate proficiently have a very important impact on the driver’s on-the-spot performance. Likewise, the CNC system’s bell-shaped acceleration/deceleration and track-to-be-processed monitoring functions use slow acceleration/deceleration instead of sudden shifting to ensure smooth acceleration of the machine.

Beyond that, there are other similarities between racing cars and CNC systems. The power of the racing engine is similar to the CNC drive and motor, the weight of the racing car can be compared with the weight of the moving components in the machine tool, and the stiffness and strength of the racing car are similar to the strength and rigidity of the machine tool. The CNC’s ability to correct certain path errors is very similar to the driver’s ability to keep the car in the lane.

Another parallel with the current CNC is that the cars that are not the fastest tend to require well-rounded drivers. In the past, only high-end CNC could ensure high machining accuracy while cutting at high speed. Today, it is also possible to do the job satisfactorily with the capabilities that are available in low- and mid-range CNCs. While a high-end CNC has the best performance currently available, there is also the possibility that you are using a low-end CNC with the same machining characteristics as a mid-to-high-end CNC in its class. In the past, the factor that limited the maximum feed rate for mold processing was the CNC, but today it is the mechanical structure of the machine tool. Even better, CNCs won’t improve performance when the machine is already at its performance limit.

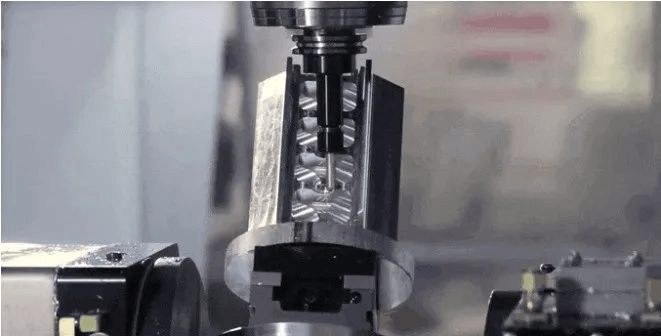

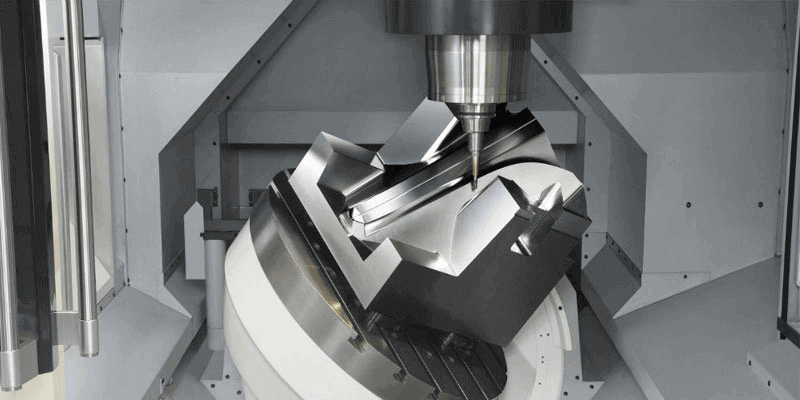

The best CNC machining method – 5 axis CNC

5 axis CNC machining is becoming more and more widely used in the manufacture of complex molds. Using 5-axis machining reduces the number of tooling or/and machine tools required to machine apart, minimizing the amount of equipment required for the machining process and reducing overall machining time. The ever-increasing capabilities of CNC have allowed CNC manufacturers to offer more 5-axis features.

Functions that used to be only available in high-end CNC are now also used in mid-range products. For those manufacturers who have never used 5 axis CNC machining technology, the application of these features makes 5-axis machining easier. Using the current CNC technology for 5-axis machining enables 5-axis machining to have the following advantages:

- Reduce the need for special tools;

- Allows setting the tool offset after completing the part program;

- Support the design of common programs so that the post-processed programs can be used interchangeably between different machine tools;

- Improve the quality of finishing;

- It can be used for machine tools of different constructions, so it is not necessary to specify in the program whether the spindle or the workpiece is rotating about the center point because the parameters of the CNC will solve this.

We can use the example of compensation of spherical milling cutters to illustrate why 5 axes are particularly suitable for mold machining. To accurately compensate the offset of the spherical milling cutter when the part and the tool rotate around the central axis, the CNC must be able to dynamically adjust the compensation amount of the tool in the three directions of X, Y, and Z. Ensuring the continuity of the cutting contact of the tool is conducive to improving the quality of finishing.

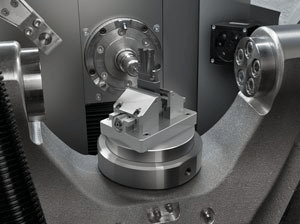

In addition, 5-axis CNC is used for features related to rotating the tool around the spindle, features related to rotating the part around the spindle, and features that allow the operator to manually change the tool vector.

The original tool length offset in the Z-axis direction is divided into 3 components in the X, Y, and Z directions, when the rotation axis is the center axis of the tool. And the tool diameter offset in the original X and Y-axis directions is also divided into three components in the X, Y, and Z-axis directions. In cutting engineering, the tool can be fed in the direction of the axis of rotation, so all these offsets must be dynamically updated to accommodate the changing orientation of the tool.

Another feature of CNC called “tool center point programming” allows the programmer to define the tool’s path and center point speed. The CNC ensures that the tool moves according to the program through commands in the direction of the rotary axis and the linear axis. This feature makes the center point of the tool no longer change with the change of the tool, which also means that in the five-axis machining, the tool offset can be directly input as in the three-axis machining, and the change of the tool length can be explained by post-programming again. This kinematic behavior of the shaft by rotating the spindle simplifies the post-processing of the programming of the tool.

Using the same function, the workpiece can be rotated around the central axis, and the machine tool can also obtain rotary motion. The newly developed CNC can match the motion of the part by dynamically adjusting the fixed offset and rotational axes. The CNC system also plays an important role when the operator uses the manual method to realize the slow feed of the machine tool. The newly developed CNC system also allows the axis to be jogged in the direction of the tool vector and, without changing the position of the tool nose, to change the direction of the tool nose vector (see illustration above).

These features make it easy for operators to use the 3+2 programming method currently widely used in the mold industry when using a five-axis machine tool. However, with the gradual development and acceptance of new 5-axis machining capabilities, true 5-axis tooling machines may become more common.

Do NC and CNC mean the same thing?

From the above, we know that NC uses discrete digital information to control the operation of machinery and other devices through engineering programming. CNC refers to the entire process of engineering programming to produce parts through CNC machines.

With the development of industrial globalization, manufacturers in many different countries can provide non-local CNC machining services. For example, JTR is a professional manufacturer of CNC machining services and CNC customized machining services. Manufacture the grinding tools and parts that customers all over the world want in China. And the low price has always had many long-term cooperative customers. Please contact us if you also want the most professional CNC machining services. Our engineers will provide you with the most suitable technical solution for you.