In the surface heat treatment process, because the names of carbonitriding and nitrocarburizing are very similar, some people may confuse the two processes. This article will explain what these two processes are, and what are the differences between them?

What is Carbonitriding?

Carbonitriding refers to the chemical heat treatment process in which carburizing is the main process and nitrogen is simultaneously infiltrated. To some extent, it overcomes the shortcomings of high hardness of nitrided layer but shallow nitrided layer, and large hardening depth but low surface hardness of carburized layer.

What Are the Characteristics of Carbonitriding?

1. Characterized by carburizing with a small amount of nitrogen.

2. It can be divided into gas, liquid and solid according to the state of the penetrating medium. Solid and liquid carbonitriding are rarely used.

3. The mechanical properties of gas carbonitriding give consideration to the advantages of carburized layer and nitrided layer.

Compared with the carburized layer, the surface hardness is higher, the wear resistance and corrosion resistance are better, and the fatigue limit of the steel is improved.

Compared with nitriding, the depth of the carbonitriding layer is deep and the surface brittleness is small.

What is the Difference Between Carbonitriding and Carburizing?

- Compared with carburizing, it has a faster infiltration speed.

- The carbonitriding layer has higher hardenability and tempering resistance, better fatigue resistance and wear resistance.

- The treatment temperature is low, which is often used to replace carburizing treatment.

- The production process is simplified, the energy is saved, and the deformation of die parts is reduced.

What is Nitrocarburizing?

Nitrocarburizing is a process in which nitrogen and carbon elements are simultaneously infiltrated on the surface of the workpiece. The process can be carried out in gas, liquid, solid and other media.

What Are the Characteristics of Nitrocarburizing?

1. Nitriding is the main and carburizing is the auxiliary. The performance after carburizing is more ideal than that of single nitriding or carburizing, and it is widely used.

2. The treatment temperature is low (generally 500-600 ℃).

3. The hardness of nitrocarburizing rapid cooling is much higher than that of slow cooling (about 10HRC higher). Therefore, when nitrocarburizing, especially carbon steel must be cooled quickly, such as oil cooling, for this reason.

What is the Difference Between Nitrocarburizing and Nitriding?

1. Carbon and nitrogen promote each other in the process of nitrocarburizing, so the nitrocarburizing speed is much higher than the single nitriding speed.

2. The bright white compound layer after nitrocarburizing does not show brittleness.

What is the Difference Between Carbonitriding and Nitrocarburizing?

1. The amount of carbon and nitrogen infiltrated is different

Carbonitriding: It mainly penetrates into carbon, but also nitrogen.

Nitrocarburizing: It mainly penetrates into nitrogen, but also carbon.

2. Different treatment temperatures

Carbonitriding: the commonly used temperature is 820-880 ℃.

According to the difference of the temperature, there are three kinds of carbonitriding: low temperature (500 ℃~ 600 ℃), medium temperature (700 ℃~ 800 ℃) and high temperature (900 ℃~ 950 ℃).

Nitrocarburizing: Nitrocarburizing temperature is generally 500-600 ℃, and 560-570 ℃ is preferred.

3. In a broad sense, carbonitriding can be divided into carbonitriding and nitrocarburizing.

Nitrocarburizing (soft nitriding) is to infiltrate nitrogen and carbon into the surface of steel parts in the medium containing active carbon and nitrogen atoms. And it is a low temperature carbonitriding process mainly based on nitriding.

Carbonitriding is mainly carburizing, with medium and high temperature carbonitriding.

This paper introduces carbonitriding and nitrocarburizing, which are surface heat treatment processes with some micro differences.

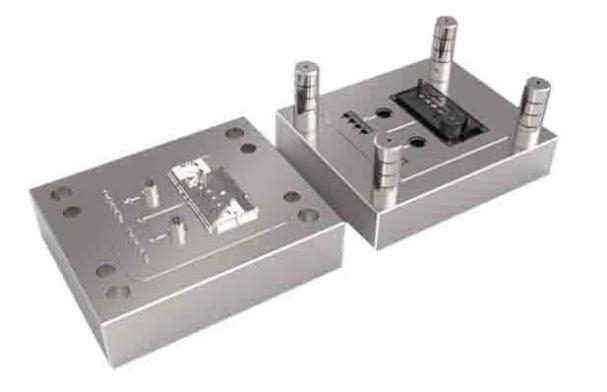

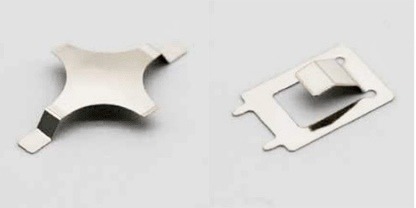

JTR has been committed to high-quality mold making and mass and small batch production. It adopts a variety of processes, including CNC machining, die-casting, 3D printing, rapid tooling and injection molding, etc., and provides surface treatment design and services according to the specific use needs of customers. If you need, please contact us!