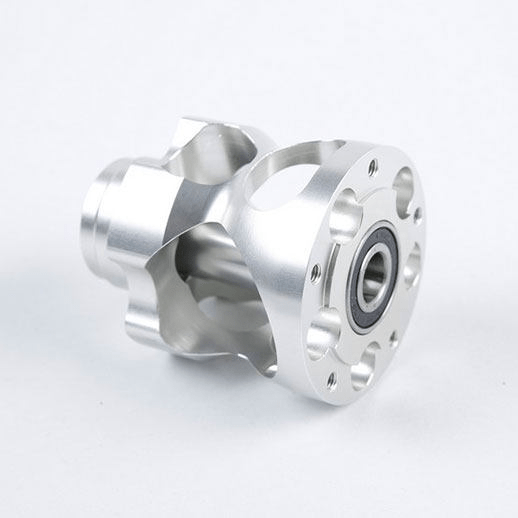

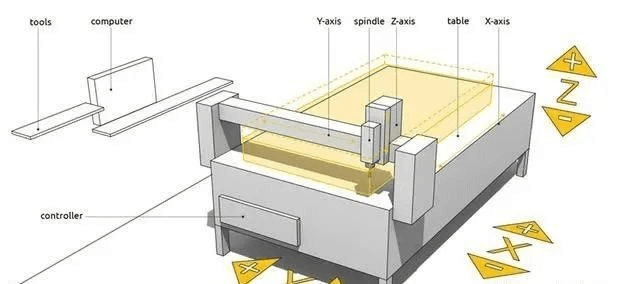

The manufacture and processing of products or parts under the control of a computer is CNC machining. CNC machining is the automatic removal of material by computer numerical control (CNC) machines to shape and resize a piece of material or workpiece. Usually, the material used for CNC machining is plastic or metal, and when the removal is complete, the finished product is produced.

Understanding CNC Machining Services

This process is also known as subtractive manufacturing. A computer application is usually required to control the movement of the machine tool to perform CNC machining.

Types of Common CNC Machining Techniques

CNC machining processes include the most common CNC milling and CNC turning, followed by grinding, electrical discharge machining, etc.

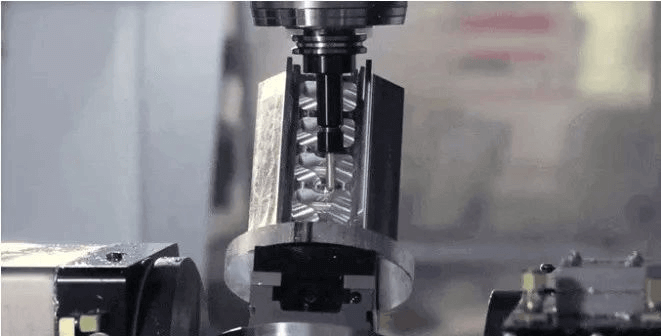

CNC Milling

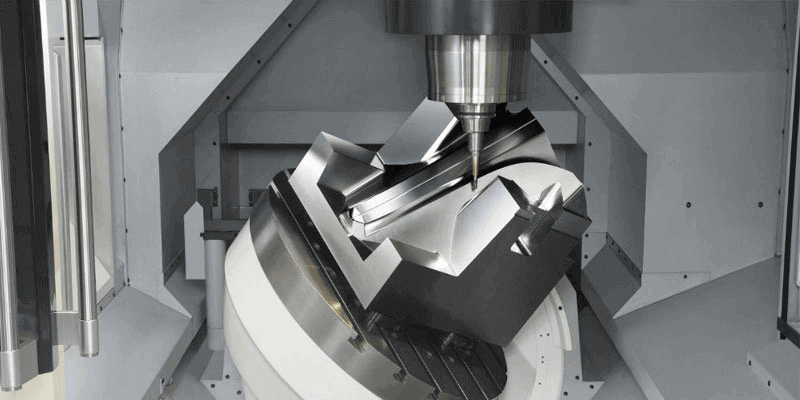

CNC Milling is the application of a rotary tool to the workpiece surface, moving along 3, 4, or 5 axes. CNC Milling is the cutting or trimming of workpieces, allowing complex geometries and precision parts to be quickly machined from metals or thermoplastics.

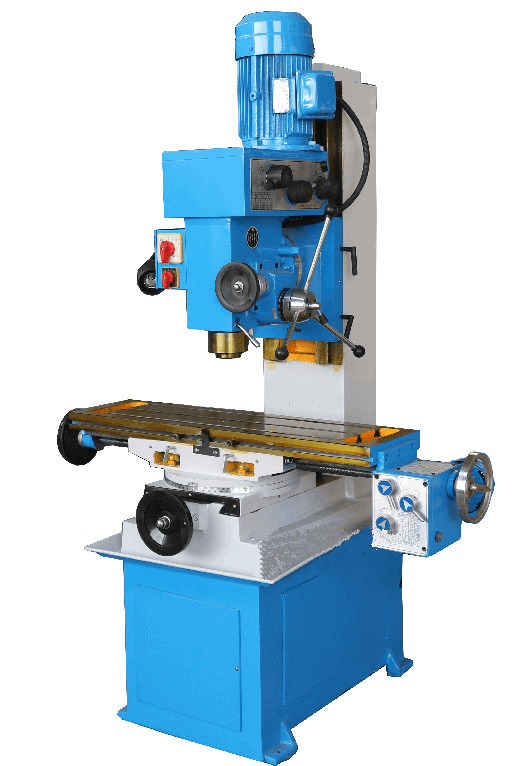

CNC milling machine is automatic processing equipment developed later, which is based on an ordinary milling machine. The processing technology of the two is basically the same, and the structure is also somewhat similar. CNC milling machines are divided into two categories: without tool magazines and with tool magazines. CNC milling machines with tool magazines are also known as machining centers.

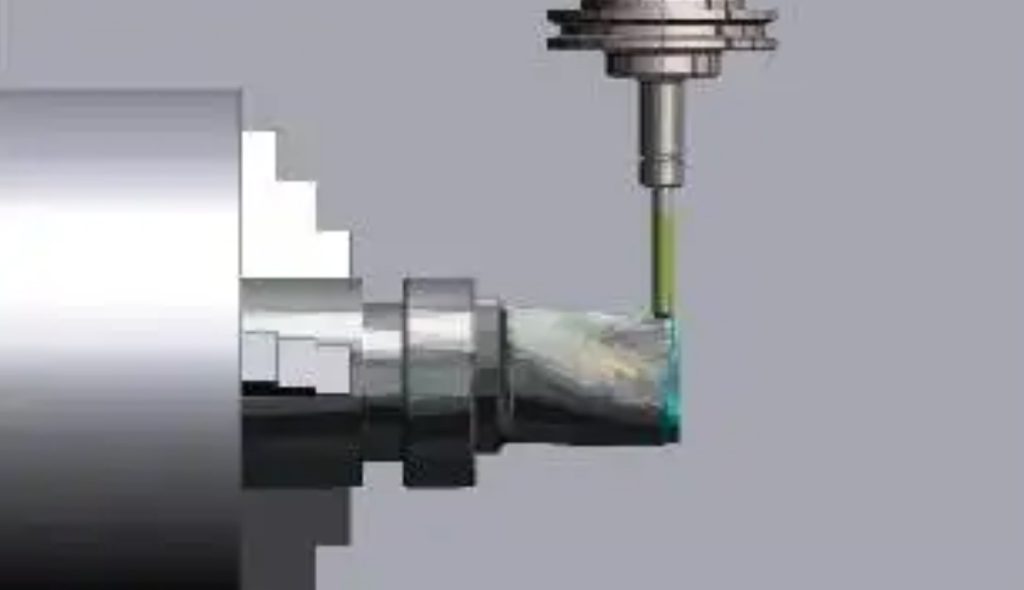

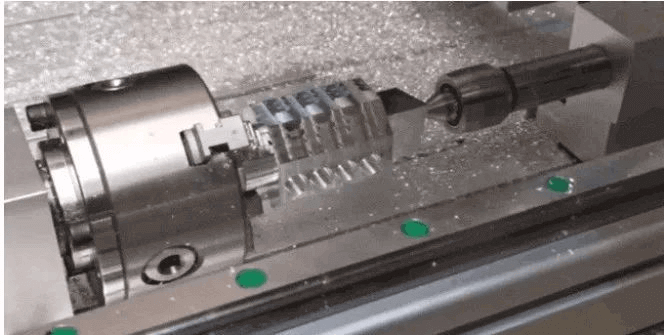

CNC Turning

CNC turning is the use of a lathe to manufacture parts containing cylindrical features. The workpiece rotates on a shaft and contacts a precision turning tool to form rounded edges, radial and axial holes, and grooves.

Advantages of CNC Machining

Compared with traditional manual machining, CNC machining is more efficient. If the computer coding is correct and conforms to the design, the precision of the finished dimension is high, and the error is small.

CNC manufacturing is an ideal manufacturing method for rapid prototyping. It can also be used to manufacture end-use products and components but is usually only cost-effective in low-volume, short-run production.

Differences between Multi-axis CNC Machines

CNC machining involves the use of rotating tools to remove material. The workpiece remains stationary, the tool moves onto the workpiece, or the workpiece enters the machine at a predetermined angle. The more axes of motion the machine has, the faster and more complex the forming process will be.

3-axis CNC Machining

3 axis CNC machining remains one of the most popular and widely used machining processes. In 3-axis machining, the workpiece remains stationary, and the rotating tool cuts along the x, y, and z axes. This is a relatively simple form of CNC machining that produces products with simple structures. It is not suitable for machining complex geometries or products with complex components.

Since only 3 axes can be cut, machining speeds can be slower than using a 4- or 5-axis CNC. It may be necessary to manually reposition the workpiece to obtain the desired shape.

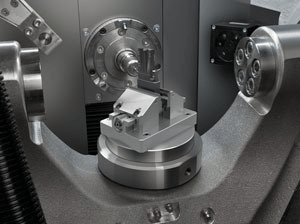

4-axis CNC Machining

In 4 axis CNC machining, a fourth axis is added to the motion of the cutting tool, allowing rotation around the x-axis. There are now four axes: x-axis, y-axis, z-axis, and a-axis (rotation around the x-axis). Most 4-axis CNC machines also allow the workpiece to rotate, which is called the b-axis, so that the machine can function as both a milling machine and a lathe.

4-axis CNC machining is a more accurate explanation: 4-axis CNC machining refers to four-axis linkage. First of all, the lathe must have four controllable axes, and the four axes can perform interpolation motion control at the same time. That is, the four axes can realize simultaneous linkage control.

The movement speed of this simultaneous linkage is the combined speed, not the respective motion control. It is the simultaneous movement of one point in space through the four axes to reach another point in space. It moves simultaneously from the starting point and stops at the same time at the endpoint. The motion speed is the speed of each axis which is synthesized internally by the motion interpolation algorithm of the controller according to the programmed speed.

For the 4-axis machining center, it is the X, Y, Z-axis plus a rotation axis A (it can also be the B axis or the C axis). The definitions of the A, B, and C axes correspond to the rotation around the X, Y, and Z axes respectively. Axis, generally the fourth axis is the A-axis whose axis rotates around the X-axis or the B axis whose axis rotates around the Y-axis, which depends on the installation position of the fourth axis on the actual machine tool), and this fourth axis not only It can move independently and can also be linked with one other axis or two axes or these four axes at the same time.

Some machine tools have four axes, but they can only move alone and can only be used as an indexing axis. 4 axes and 3 linkages. Similarly, a 4-axis linkage machine tool can have more than 4 axes in total or five or more axes, but the maximum number of linkage axes is 4.

If you need to drill holes on the side of a part of the surface of a cylinder, 4-axis CNC machining is the way to go. This can greatly speed up the machining process, and the machining accuracy is also high.

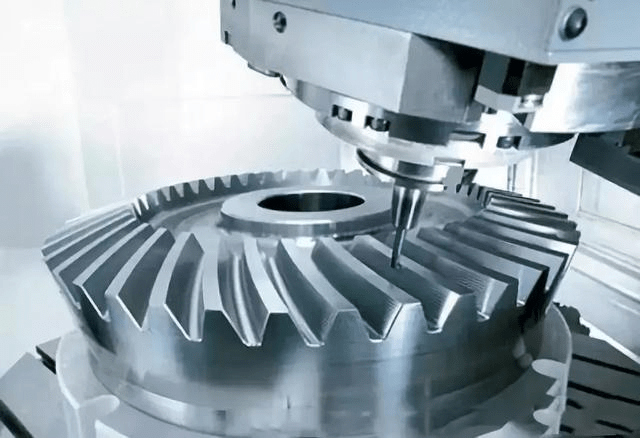

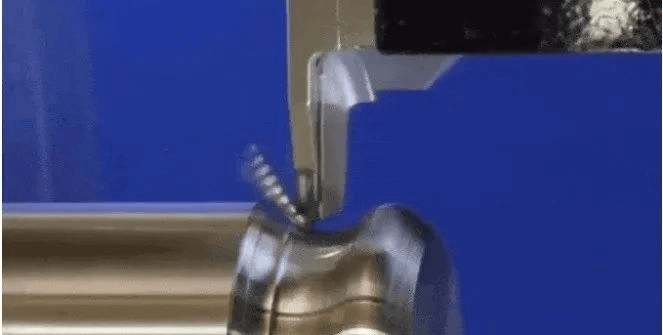

5-axis CNC Machining

5 axis CNC machining has an additional axis of rotation compared to 4-axis CNC. The fifth axis is the rotation around the y-axis, also known as the b-axis. The workpiece can also be rotated on some machines, sometimes called the b-axis or c-axis.

Due to the high versatility of 5-axis CNC machining, it can be used to manufacture complex precision parts. Such as medical parts for prostheses or bones, oil and gas machinery parts, aerospace parts, and military products.

How Should We Choose 3-axis, 4-axis, or 5-axis CNC Machining?

3-axis, 4-axis, and 5-axis CNC machining are not comparable. For example, your family wants to buy a car. Do you think it is better to buy a super sports car? Or a heavy-duty truck or an ordinary family car? Naturally, you have to consider many aspects, such as how much you plan to spend on buying a car, what to do with the car you bought, etc.

In the same way, the 3-axis and 4-axis have their areas of expertise. Some parts are economical and economical to use 3-axis, and some parts must be made with 4-axis, and 3-axis CNC machining cannot be done. However, we can analyze it according to the actual situation. In reality, most parts can be processed by 3-axis CNC machining. Besides, 4-axis machine tools are generally more expensive than 3-axis machine tools. Just buy a 3-axis machine tool first. That way, the price is lower. Of course, you can also think about it this way, buy a 4-axis machine tool, 3-axis parts can be made, and 4-axis parts can also be made so that it can be done in one step.

Of course, you don’t have to worry about it either. JTR provides professional CNC machining services. You don’t need to worry about how to choose the right machine for processing, you need to tell us your needs, and we will help you realize the production of the product. If you would like to know more about JTR’s CNC machining services, please get in touch with us.