Metal casting is one of the most trusted and widely used manufacturing processes in the automotive industry. It’s essential for producing key components like engine blocks, cylinder heads, and transmission housings, all of which directly impact a vehicle’s performance and durability.

But with multiple casting methods available—each with its strengths—what is the best casting method for automotive parts? The truth is, there’s no one-size-fits-all answer. It depends on several key factors:

- Part complexity

- Production volume

- Required mechanical strength

- Cost-efficiency

- Material type

These factors all play a role in determining the ideal casting method for your project.

The global automotive casting market is projected to hit $96.5 billion by 2027. With modern vehicles containing 50 to 150 cast components, selecting the right process is critical for maintaining a competitive edge in cost, quality, and performance.

Top 5 Casting Methods for Automotive Parts – Comparison Table

| Casting Method | Best For (Part Type) | Cycle Time | Dimensional Accuracy | Cost Profile | Material Strength (UTS) |

| High-Pressure Die Casting (HPDC) | Engine housings, EV battery trays, transmission cases | 30–60 seconds | ±0.1–0.3 mm | High tooling cost, low unit cost | 250–320 MPa |

| Sand Casting | Large housings, prototypes, complex geometries | 4–48 hours | ±1.0–2.5 mm | Low tooling cost, good for small batches | 200–250 MPa |

| Investment Casting | Turbo blades, small brackets, detailed components | 24–72 hours | ±0.05–0.1 mm | High per-part cost, excellent surface finish | 400–550 MPa |

| Low-Pressure Die Casting (LPDC) | Wheels, chassis parts, suspension arms | 2–5 minutes | ±0.2–0.5 mm | Medium cost, ideal for aluminum alloys | 270–310 MPa |

| Squeeze Casting | Safety-critical structural parts (e.g. suspension) | 1–3 minutes | ±0.15–0.3 mm | Higher cost, suitable for high-strength needs | 300–380 MPa |

Which Casting Method Suits Your Application?

| Casting Method | Typical Automotive Applications | Key Advantages |

| High-Pressure Die Casting (HPDC) | EV components, engine housings, transmission cases | High efficiency, excellent dimensional precision, ideal for high-volume production |

| Sand Casting | Cylinder heads, manifolds, gear housings, large castings | Low cost, high flexibility, rapid prototyping |

| Investment Casting | Turbo parts, small brackets, intricate components | Superior surface finish, handles complex geometries, high accuracy |

| Gravity Casting | Suspension links, steering knuckles, chassis structures | Consistent mechanical properties, lower tooling cost |

| Centrifugal Casting | Brake drums, cylindrical parts, pipe fittings | Dense structure, no porosity, high strength |

Key Factors to Consider When Selecting a Casting Method

| Decision Factor | Suggested Method |

| Production Volume | HPDC for high-volume; sand casting for prototypes and small batches |

| Part Complexity | Investment casting for intricate shapes and internal cavities |

| Material Type | Aluminum/magnesium for die casting; ductile iron for sand casting |

| Tolerance Requirements | High precision needs → die casting or investment casting |

| Cost Sensitivity | Low initial budget → sand casting; long-term savings in large batches → HPDC |

Top Recommendation: High-Pressure Die Casting (HPDC)

For high-speed production, lightweight design, and precision parts, HPDC is the industry’s go-to method—especially for electric vehicle (EV) structures and core powertrain components.

| Category | HPDC Advantages |

| Production Speed | 50–200 parts per hour, supports JIT (Just-In-Time) manufacturing |

| Material Efficiency | Up to 95% utilization—more sustainable and cost-effective than sand casting |

| Post-Machining | The near-net shape reduces follow-up machining by 60–80% |

| Cost Effectiveness | Unit cost drops by 40–60% when volumes exceed 100,000 pieces |

| Weight Optimization | Supports wall thicknesses as low as 2–3 mm; ideal for lightweight aluminum/magnesium alloys |

When to Consider Alternative Methods

| Casting Method | Best Use Cases |

| Sand Casting | Prototyping, large castings (>500 kg), special alloys like ductile iron |

| Investment Casting | High-temperature alloys, miniature or complex precision parts, aerospace-grade applications |

| Squeeze Casting | Safety-critical parts (e.g. suspension arms, cockpit structures), ideal for T6 heat-treated alloys |

There Is No Single “Best” Method—Only the Most Suitable One

| Your Need | Recommended Casting Method |

| High precision + high volume | High-Pressure Die Casting (HPDC) |

| Cost-sensitive + low volume + complex shape | Sand Casting |

| Ultra-precise + small intricate parts | Investment Casting |

| Load-bearing / structural safety parts | Squeeze Casting / Gravity Casting |

Choosing the right casting method directly impacts your product’s performance, production cost, delivery timelines, and post-processing strategy.

Need Help Finding the Right Casting Solution?

We offer end-to-end automotive casting services, including HPDC, sand casting, investment casting, and gravity casting. Whether you’re prototyping or ready for mass production, our team can help you choose the optimal process.

Contact us today for a free consultation or request a quote!

Our Metal Casting Equipment

Application Industry

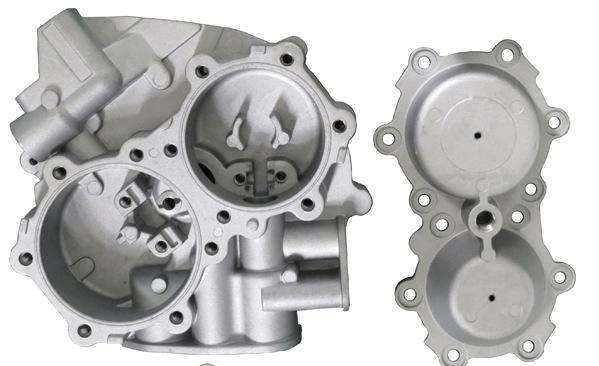

Motorcycle manufacturing

Motor manufacturing

Car manufacturer

Internal combustion engine production

Oil pump manufacturing

Instrument