Milled steel plays a crucial role in modern manufacturing, providing high precision and excellent surface finish through advanced milling techniques. This blog will explore what milled steel is, its advantages and disadvantages, key processes, material types, apply.

What is Milled Steel?

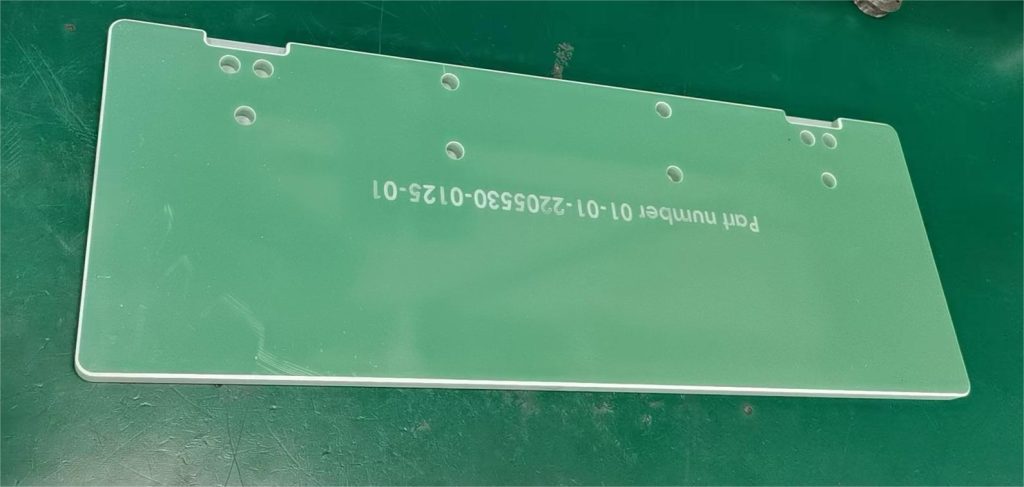

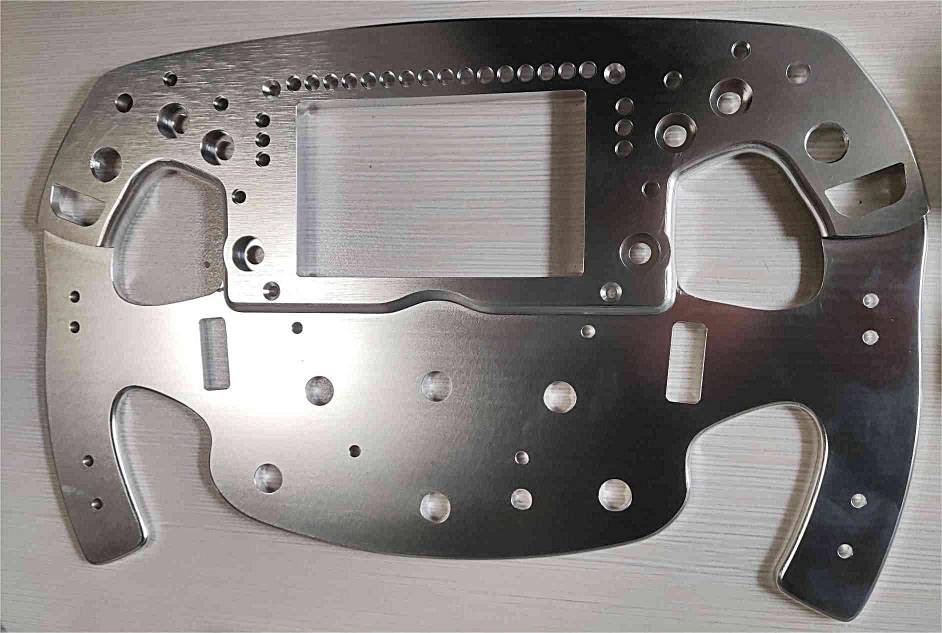

Milled steel refers to steel that has undergone a milling process, where a rotating cutting tool removes material to achieve the desired shape, surface quality, and dimensional accuracy. The process can include:

- Conventional Milling: Used for general machining such as flat surfaces, slots, and holes.

- High-Speed Hard Milling: Applied to hardened steel (e.g., tool steel SKD11) for precision machining, reducing the need for post-processing like grinding.

Difference Between Milled Steel and Other Steel Types

| Steel Type | Processing Method | Key Features | Common Applications |

| Milled Steel | Milling (Cutting with rotary tools) | High precision, smooth surface | Precision parts, molds, machinery |

| Forged Steel | Hammering/pressing heated metal | High strength, impact resistance | Automotive, aerospace, heavy machinery |

| Cast Steel | Molten steel poured into molds | Complex shapes, lower machining needs | Valves, pump housings, large industrial parts |

| Rolled Steel | Hot or cold rolling | High ductility, uniform properties | Beams, sheets, structural components |

Advantages and Disadvantages of Milled Steel

Advantages

✅ High Precision: Achieves tight tolerances (±0.01mm), making it ideal for detailed machining.

✅ Superior Surface Finish: Reduces the need for post-processing such as grinding.

✅ Customizable: Can be milled into complex shapes and intricate geometries.

✅ Material Utilization: Minimizes waste, especially compared to forging or casting.

Disadvantages

❌ Higher Cost: Milling, especially CNC milling, can be expensive due to machine time and tooling.

❌ Longer Processing Time: Compared to hot rolling or forging, milling requires more steps to achieve the final shape.

❌ Limited Large-Scale Production: Not as efficient for high-volume, low-cost production as casting or rolling.

Key Milling Processes and Technologies

| Process | Description | Common Applications |

| Conventional Milling | Uses rotating tools to cut materials into shapes | General machining, flat surfaces, and slots |

| High-Speed Hard Milling | Utilizes advanced cutters for hardened materials | Precision molds, die components, aerospace parts |

| CNC Milling | Automated milling using computer-controlled machines | Mass production, complex geometries |

High-speed hard milling is particularly useful in machining hardened steel molds, reducing the need for electrical discharge machining (EDM) or additional grinding.

Material Types and Properties of Milled Steel

Different steel grades are selected based on machinability, hardness, and application.

Common Types of Milled Steel

| Steel Type | Example | Properties | Application |

| Low Carbon Steel | SAE 1020 | Easy to machine, low cost | General-purpose machining, structural components |

| Hardened Steel | SKD11 (Tool Steel) | High hardness, wear-resistant | Molds, cutting tools, precision parts |

| Alloy Steel | Mn 0.9%–1.6% | High strength, specialized uses | Steel fiber manufacturing, automotive parts |

Performance Advantages of Milled Steel

- High Surface Quality: Reduces machining marks, improving product durability.

- Dimensional Stability: Precision tolerance control (±0.01mm).

- Improved Material Efficiency: Less need for secondary processing like grinding or EDM.

Applications of Milled Steel

Milled steel is widely used across multiple industries due to its versatility and precision.

| Industry | Application Examples |

| Automotive | Engine components, transmission gears, chassis parts |

| Aerospace | Aircraft structural components, landing gear, turbine blades |

| Construction | Steel beams, connectors, support frames |

| Manufacturing | CNC-machined machine parts, tooling, dies |

| Medical | Surgical instruments, orthopedic implants |

How to Choose the Right Milled Steel?

When selecting milled steel, consider these factors:

1. Application Requirements

- If high strength is needed → Choose hardened tool steel (SKD11, D2, etc.)

- If cost-efficiency is a priority → Choose low-carbon steel (SAE 1020, A36, etc.)

2. Machining Capabilities

- For conventional machining, → Use easily machinable steels (1020, 1045)

- For precision molds or aerospace parts → Use hardened steel with CNC or high-speed milling

3. Cost vs. Performance

- Lower-cost options like mild steel work for general applications.

- For high-wear applications, investing in alloy or hardened steel improves durability.

4. Industry Standards & Certifications

- Check compliance with ISO, ASTM, or SAE standards based on your industry needs.

Milled steel remains a fundamental material in precision manufacturing, ensuring high-quality, high-performance components across various industries. Advancements in high-speed milling and CNC automation continue to play a key role in modern engineering.

By understanding its properties, applications, and selection criteria, businesses can optimize their material choices for efficiency, durability, and performance.

JTR provides CNC milling services for custom CNC parts of any specification or material. JTR can help you quickly create designs from simple straight lines to complex geometric shapes and deliver them quickly. Would you like assistance in selecting the right milled steel for a specific application? Let us know in the comments!

CNC Milling Service Supplier

JTR provides CNC milling services for custom CNC parts of any specification, in any material. JTR can help you quickly create designs from simple straight lines to complex geometric shapes and deliver them quickly.