Stainless steel dominates a wide range of industries, from soaring skyscrapers to intricate medical instruments. Stainless steel has a high tensile strength, making it ideal for bearing heavy loads while resisting wear and tear. Unlike its rusty cousin, carbon steel, stainless steel forms a chromium oxide layer that protects it from corrosion. Stainless steel’s sleek and polished appearance adds elegance to any setting. Its inherent beauty lends a modern, sophisticated feel from architectural facades to kitchen countertops. Machining is the process of sculpting stainless steel into the precise shapes and forms required for its various applications. Unlike traditional methods, CNC machining employs programmed instructions to guide the tools, eliminating human error and ensuring consistent, high-quality outcomes. CNC machines operate with microscopic precision, ensuring that all parts are identical, even in complex designs.

Typical CNC Machining Methods Used for Stainless Steel

CNC Milling

Milling is a machining process in which rotating cutters gradually remove material from a workpiece, similar to a sculptor chipping away at stone. These cutters use their sharp teeth to shave off tiny bits of metal, transforming a raw block of stainless steel into intricate features and precise shapes. Here are three major types of milling commonly used for stainless steel parts, each with its own set of advantages and applications:

1. Vertical Milling:

The workpiece is clamped to a table, and the cutter descends vertically to carve grooves, slots, and pockets into the metal. Suitable for:

- Create shallow cavities, slots, and pockets in stainless steel parts.

- Machining flat surfaces and intricate patterns on top of the workpiece.

- Suitable for small components and intricate details.

2. Horizontal Milling:

The workpiece moves horizontally past a stationary cutter, allowing for accurate shaping of the sides and edges. Suitable for:

- Machining slots, channels, and grooves on stainless steel parts.

- Creating complex profiles and intricate shapes on edges.

- Ideal for larger components with longer features.

3. Face Milling:

The cutter rotates parallel to the workpiece, removing material layer by layer to achieve flat surfaces and precise grooves. Suitable for:

- Machining flat surfaces and large pockets on stainless steel parts.

- Creating intricate patterns and features on flat surfaces.

- It is ideal for large components with high surface finishes.

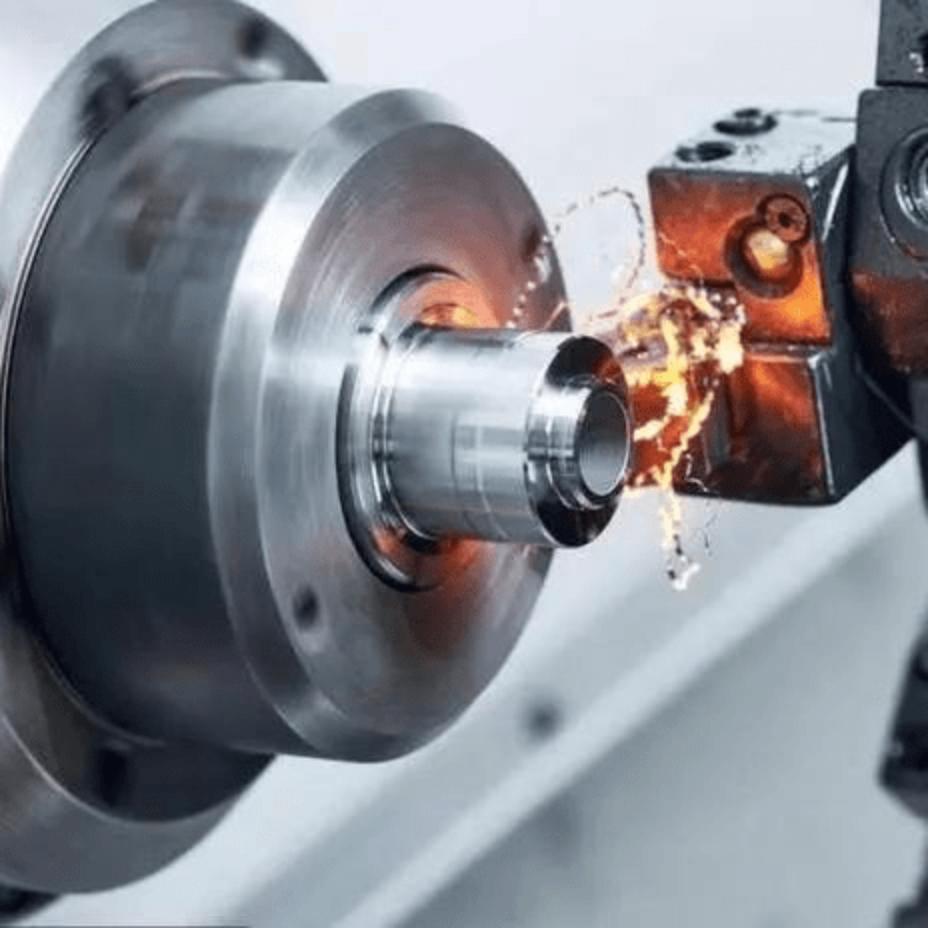

CNC Turning

A machining process in which the workpiece spins while a stationary cutting tool gently shaves away material to form it into the desired shapes and features. Here are three important types of turning operations that bring this versatile material to life.

1. Roughing:

Consider roughing the first act of the play, in which the sculptor removes large chunks of material. The cutting tool takes aggressive bites, rapidly reducing the diameter of the stainless steel bar until it approaches the final shape. Speed and efficiency are the name of the game here, laying the groundwork for more intricate details. Suitable for:

- Quickly remove excess material from the starting workpiece.

- Creating an approximate shape before proceeding to more precise turning operations.

- Suitable for large components requiring high efficiency.

2. Finishing:

Following the roughing act, the finishing step takes center stage. Here, the cutting tool works with delicate precision, removing smaller amounts of material to achieve the desired final dimensions and surface finish. Suitable for:

- Creating precise diameters and surface finishes for stainless steel components.

- Machining intricate features such as grooves, threads, and tapers.

- Suitable for both large and small components that require high accuracy.

3. Threading:

Threading adds a completely new dimension to the turning dance. Imagine the cutting tool carving delicate spirals into the rotating stainless steel, resulting in screw threads for secure fastening. This increases the functionality and versatility of various components. Suitable for:

- Creating internal or external threads on stainless steel parts for assembly.

- Suitable for bolts, nuts, shafts, and other components that require secure connections.

- Enhances functionality and versatility for machined parts.

CNC Drilling

Drilling may appear to be a simple act, but in metalworking, it is an extremely powerful tool for shaping stainless steel. Piercing through this tough material with unwavering precision, leaving precise holes of varying sizes and depths to add functionality and detail to stainless steel parts. Here are two typical types that cater to various requirements:

1. Drill Presses:

The user manually guides the drill bit into the stainless steel, adjusting the depth and angle of the hole. It’s a versatile tool ideal for small projects and single-point drilling. Capabilities:

- Suitable for drilling holes in various materials, such as stainless steel.

- Suitable for small parts and simple drilling tasks.

- Provides flexibility in hole location and angle.

- Cost-effective and easy to use.

2. CNC Drilling Centers:

CNC drilling centers use computerized instructions to guide drill bits with extreme precision. These machines can drill multiple holes of varying sizes and depths in intricate patterns, automating the process and ensuring perfect repeatability. Capabilities:

- Drills multiple holes in intricate patterns on stainless steel parts.

- Ideal for high-volume production with intricate designs.

- Provides consistent accuracy and repeatability.

- Reduces time and errors compared to manual drilling.

CNC Milling Stainless Steel vs. CNC Turning Stainless Steel

JTR provides CNC milling service and CNC turning service. There is a comparison between CNC milling stainless steel and CNC turning stainless steel and each advantage.

| CNC Milling Stainless Steel | CNC Turning Stainless Steel | |

| Process | The cutting tool moves and rotates, while the workpiece remains stationary. | The workpiece rotates, while the cutting tool remains stationary. |

| Accuracy | CNC milling is generally more accurate than CNC turning for complex shapes. | CNC turning is generally more accurate for simple shapes. |

| Surface finish | CNC milling can produce a smoother surface finish than CNC turning. | CNC turning can produce a rougher surface finish than CNC milling. |

| Part geometry | CNC milling is well-suited for parts with complex features, such as holes, slots, and curves. | CNC turning is well-suited for parts with simple features, such as cylinders, cones, and spheres. |

| Tooling | CNC milling requires more complex tooling than CNC turning. | CNC turning requires less complex tooling than CNC milling. |

| Cost | CNC milling is generally more expensive than CNC turning. | CNC turning is generally less expensive than CNC milling. |

| Production volume | CNC milling is better suited for high-volume production. | CNC turning is better suited for low-volume production. |

Advantages of CNC milling stainless steel

- Accuracy: CNC milling is more precise than CNC turning for complex shapes. This is because the cutting tool can be precisely positioned in the X-Y plane.

- Surface finish: CNC milling provides a smoother surface finish than CNC turning. This is because the cutting tool makes contact with the workpiece for a shorter period.

- Part geometry: CNC milling is ideal for parts with complex features like holes, slots, and curves. This is because the cutting tool can be moved in any direction to produce these effects.

Advantages of CNC turning stainless steel

- Cost: CNC turning is generally cheaper than CNC milling. This is because CNC turning necessitates less complex tooling and configuration.

- Production volume: CNC turning is ideal for low-volume production. This is because CNC turning machines are typically slower than CNC milling machines.

The most appropriate process for CNC machining stainless steel is determined by the part’s specific requirements. CNC milling is usually the best option for parts with complex features and high accuracy requirements. For parts with simple features and low-cost requirements, CNC turning is usually the better option.

Conclusion

Knowing the methods available allows you to compare them based on your specific needs and select the most efficient and cost-effective option for your project. Factors like part geometry, material properties, production volume, and desired finish all influence the best choice. Understanding the strengths and limitations of each method helps you optimize your machining process for speed, accuracy, and surface quality. It also allows you to avoid potential issues like tool wear, heat distortion, or poor chip control. Different methods have varying tooling costs, machining times, and material waste. Knowing the typical methods helps you estimate project costs accurately and make informed financial decisions.