In today’s rapidly evolving business landscape, innovation and speed are paramount. Companies across industries strive to develop and bring innovative products to market faster than ever before. This need for agility and efficiency has given rise to the practice of rapid prototyping.

Rapid prototyping is a process that enables the swift creation of tangible prototypes, allowing organizations to validate designs, gather user feedback, and iterate quickly. Central to the success of rapid prototyping are the various techniques and tools that facilitate the creation of these prototypes with speed, accuracy, and cost-effectiveness.

So, what are the techniques and tools that make rapid prototyping possible? Let us delve into the world of rapid prototyping and discover the cutting-edge technologies that are revolutionizing the way products are designed, tested, and manufactured.

8 Commonly Used Techniques and Tools

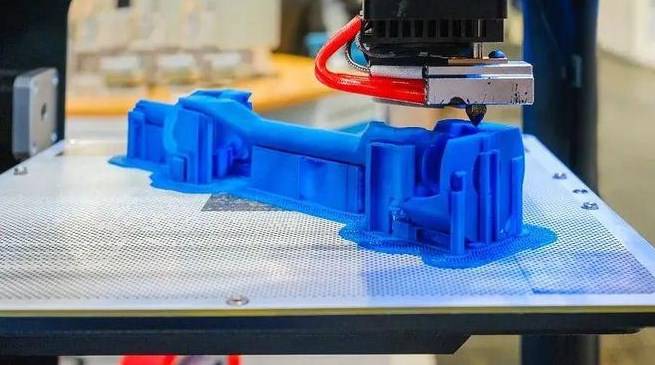

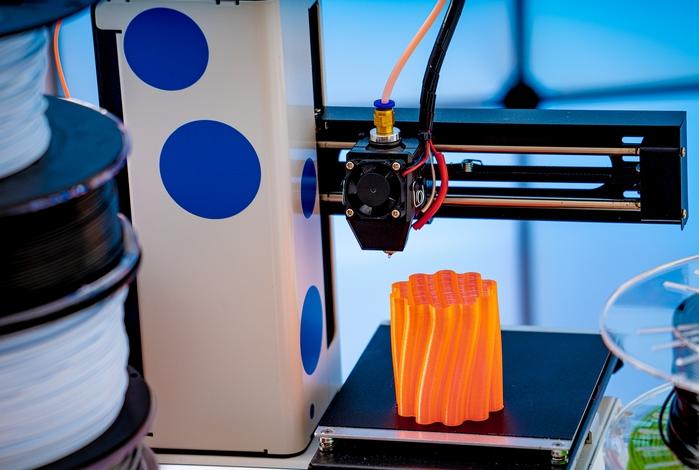

- 3D Printing

3D printing, also known as additive manufacturing, builds three-dimensional objects layer by layer based on a digital model. Various types of 3D printing technologies exist, including fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and more.

3D printing prototyping can use different materials such as plastics, resins, metals, and composites to create prototypes with high precision and intricate designs.

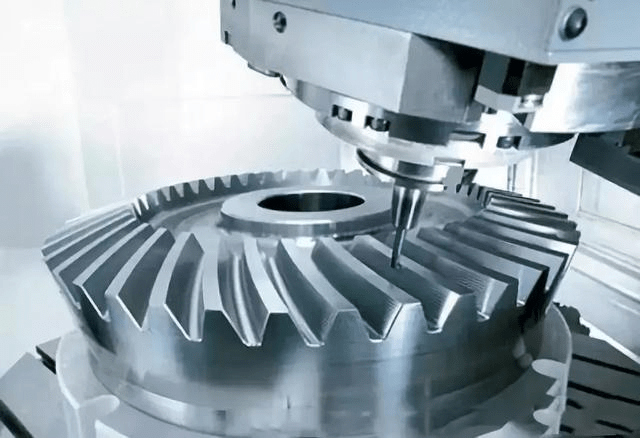

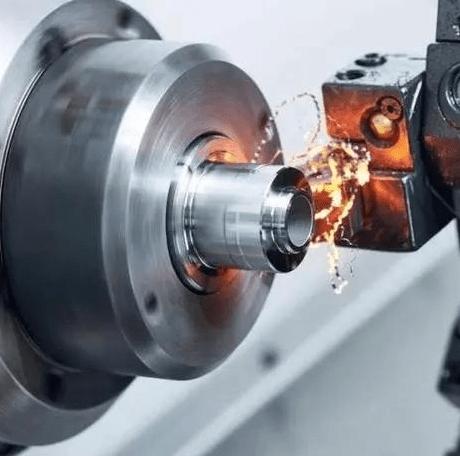

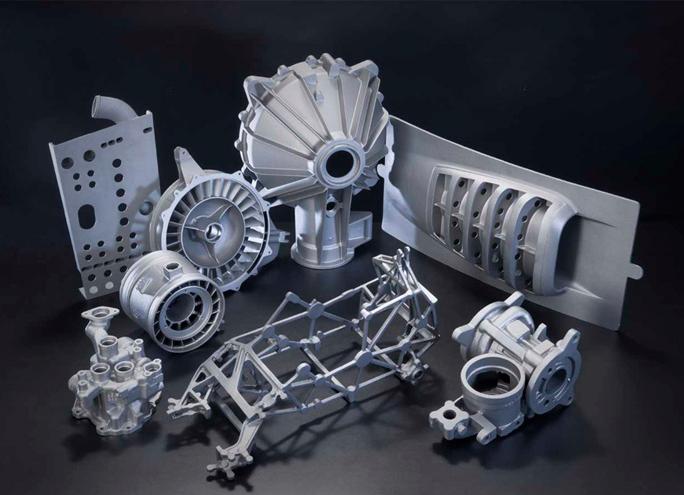

- CNC Machining

CNC machining involves the use of computer numerical control to precisely remove material from a block or sheet of material to create the desired shape. It offers high accuracy and is suitable for creating prototypes from materials like metals, plastics, and wood.

CNC machines can perform milling, turning, drilling, and other operations, making it versatile for various prototyping needs.

- Laser Cutting and Engraving

Laser cutting utilizes a high-powered laser beam to cut through or engrave materials like wood, acrylic, fabric, or paper. It enables precise and intricate cuts, allowing for the creation of complex shapes and designs.

Laser engraving adds detailed patterns, logos, or text onto the surface of materials, providing customization options for prototypes.

- Rapid Sheet Metal Prototyping

This technique involves the use of sheet metal fabrication methods like bending, cutting, and forming to quickly create prototypes of metal components.

Rapid sheet metal prototyping is commonly used in industries such as automotive, aerospace, and electronics.

- Vacuum Casting

Vacuum casting is a technique used to create small production-like series of prototypes using silicone molds. It involves pouring liquid polyurethane or other casting materials into the mold and using vacuum pressure to eliminate air bubbles and ensure precise replication of details.

- Rapid Injection Molding

Rapid injection molding allows for the creation of low-volume injection molded parts quickly and cost-effectively. It utilizes a simplified mold design and automated processes to reduce production time and cost compared to traditional injection molding.

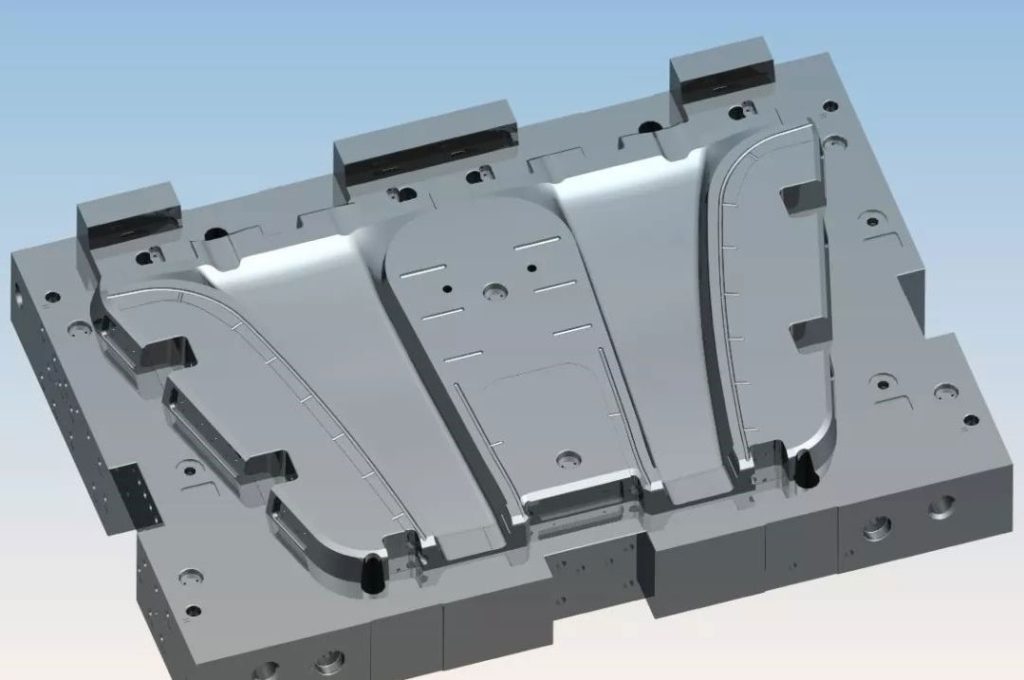

- Computer-Aided Design (CAD) Software

CAD software is essential for creating digital models of prototypes and preparing them for various rapid prototyping techniques. It enables designers to visualize, modify, and optimize their designs before manufacturing.

- Virtual Reality (VR) and Augmented Reality (AR)

VR and AR technologies provide immersive and interactive experiences for prototyping and design evaluation. They allow designers and stakeholders to visualize and interact with virtual prototypes in a realistic environment, aiding in design validation and user feedback.

These techniques and tools empower designers, engineers, and innovators to iterate quickly and efficiently, accelerating the product development process and enabling faster innovation. If you are looking for a manufacturer providing rapid prototyping services, please feel free to contact us.