In today’s advanced manufacturing landscape, CNC Turning has emerged as a highly flexible and versatile machining process. With its ability to handle a wide range of materials and tackle complex geometries, CNC Turning has revolutionized the production of intricate parts and components. This article explores the exceptional flexibility and versatility offered by CNC Turning in terms of working with different materials and managing complex geometries.

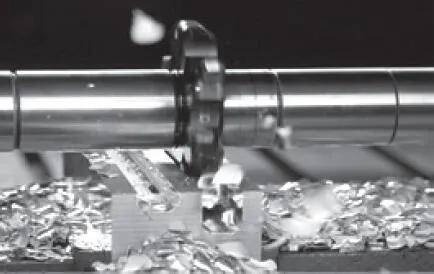

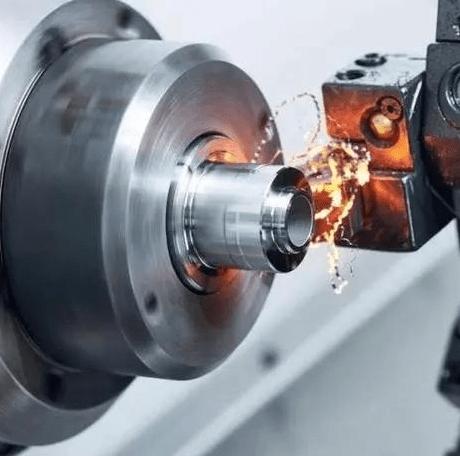

CNC Turning, also known as Computer Numerical Control Turning, refers to the process of shaping cylindrical workpieces using computer-controlled machines. It involves the rotation of a workpiece while a cutting tool removes material to create the desired shape, size, and surface finish. What sets CNC Turning apart is its ability to adapt to diverse materials, such as metals, plastics, and composites, as well as its capability to handle complex geometries with precision and efficiency.

4 Aspects of the Flexibility and Versatility of CNC Turning

CNC Turning offers exceptional flexibility and versatility when it comes to working with various materials and handling complex geometries. Here’s an exploration of how CNC Turning excels in these areas:

- Materials in CNC Turning

Metals: CNC Turning can handle a wide range of metal materials, including aluminum, steel, stainless steel, brass, titanium, and more. The machines are capable of efficiently cutting, shaping, and finishing these metals to precise specifications.

Plastics: CNC Turning is well-suited for machining plastic materials such as ABS, PVC, acrylic, nylon, and polycarbonate. The machines can accurately cut, drill, and shape plastics, making them ideal for industries like automotive, electronics, and consumer goods.

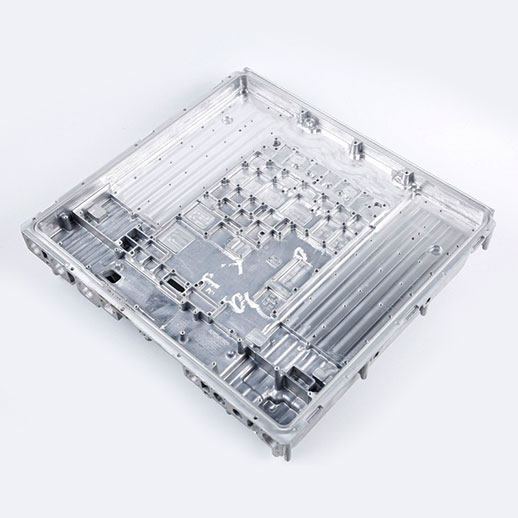

Composites: CNC Turning is capable of working with composite materials, including carbon fiber, fiberglass, and laminates. The machines can precisely machine these materials without delamination or damage, allowing for the production of lightweight, strong, and complex composite parts.

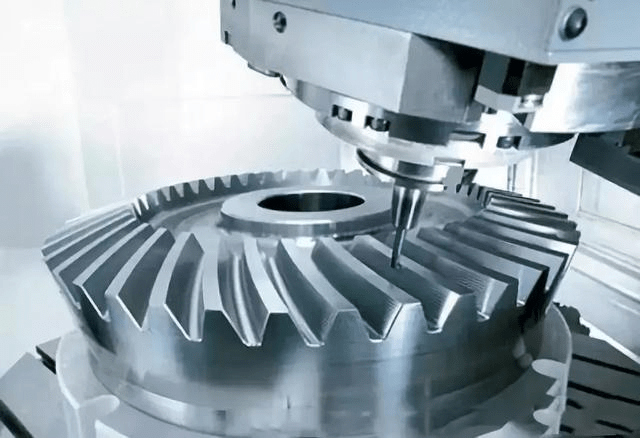

- Complex Geometries in CNC Turning

Contours and Profiles: CNC Turning machines excel in creating complex contours, profiles, and curves. They can follow precise tool paths to produce intricate shapes and features on cylindrical workpieces, including tapered profiles, radii, chamfers, and intricate curves.

Threads and Tapers: CNC Turning enables the production of precise threads, both internal and external, on cylindrical parts. This includes standard thread profiles, custom threads, and various thread pitches. Additionally, CNC Turning can create tapered features, such as conical shapes and tapered bores.

Multi-Axis Machining: Advanced CNC Turning machines with multi-axis capabilities, such as live tooling and Y-axis, enable the machining of complex geometries in a single setup. This allows for simultaneous milling, drilling, and turning operations, expanding the range of possible geometries and reducing the need for additional setups.

- Prototyping and Customization in CNC Turning

Rapid Prototyping: CNC Turning enables rapid prototyping by translating digital designs into physical parts quickly and accurately. The ability to program and reprogram CNC machines allows for efficient iteration and refinement of designs during the prototyping phase.

Customization: CNC Turning facilitates customization by easily adapting to different part designs and specifications. Our CNC Turning Service can modify the programming to produce parts with unique features, sizes, and geometries, catering to specific customer requirements.

Tooling Adaptability in CNC Turning

Tooling Options: CNC Turning offers a wide selection of cutting tools, inserts, and holders to accommodate different materials and machining requirements. Various tool geometries, coatings, and cutting parameters can be employed to optimize the machining process for specific materials and geometries.

Quick Tool Changes: CNC Turning machines allow for quick tool changes, minimizing setup time and enabling efficient machining of different parts or features within a production run. This versatility and tooling adaptability enhance the overall flexibility of CNC Turning.

Summary

In summary, CNC Turning provides remarkable flexibility and versatility in working with a diverse range of materials and handling complex geometries. Whether it’s metals, plastics, composites, or intricate shapes and profiles, CNC Turning machines can deliver precise and efficient machining results, making it an indispensable technique in various industries.