Thread machining is one of the very important applications of CNC machining centers. The machining quality and efficiency of the threads will directly affect the machining quality of the parts and therefore the production efficiency of the machining center. With the development of the performance of CNC machining and so the improvement of cutting tools, the methods of threading are constantly improving, and the accuracy and efficiency of threading are gradually improving. To enable technologists to reasonably choose thread processing methods in processing, improve production efficiency and avoid quality accidents, several thread processing methods commonly utilized in CNC machining centers in practice are summarized as follows

The Most Common Method – Tap processing method

- Classification and characteristics of tap processing

Using taps to process threaded holes is the most ordinary processing method. It is mainly suitable for threaded holes with small diameters (D<30) and low hole position accuracy requirements.

In the 1980s, threaded holes all adopted flexible tapping methods, that is, flexible tapping chucks were used to hold the taps, and therefore the tapping chucks might be used for axial compensation to catch up on the advance caused by the asynchronous feed of the machine tool and the spindle speed. Show the error to make sure the correct pitch. The flexible tapping chuck owns a complex structure, high cost, easy damage, and low processing efficiency. In recent years, the performance of CNC machining centers has gradually improved, and rigid tapping has become the essential configuration of CNC machining centers.

Therefore, rigid tapping has become the most common method of thread processing at the present. That is, the tap is clamped by a rigid spring chuck, and the spindle feed and the spindle speed are controlled by the machine tool to stay equivalent. Compared with the flexible tapping chuck, the spring chuck has a simple structure, low price, and a wide range of uses. Additionally to clamping taps, it can also clamp end mills, drills, and other tools, which may reduce tool costs. At the same time, rigid tapping is often used for high-speed cutting, which improves the efficiency of the machining center and reduces manufacturing costs.

- Determination of the threaded bottom hole before tapping

The processing of the threaded bottom hole has a great influence on the life of the tap and the quality of thread processing. Generally, the diameter of the threaded bottom hole drill bit is chosen to be close to the upper limit of the threaded bottom hole diameter tolerance.

For example, the diameter of the bottom hole of the M8 threaded hole is Ф6.7+0.27mm, and the drill bit diameter is Ф6.9mm. In this way, the machining allowance of the tap can be reduced, the load of the tap can be reduced, and the service life of the tap can be increased.

- How to Choose a Tap?

When selecting a tap, first of all, you must select the corresponding tap according to the material to be processed. The tool company produces different types of taps according to the different materials to be processed. Pay special attention to the selection.

Compared with milling cutters and boring cutters, taps are very sensitive to the material being processed. For example, the use of taps for machining cast iron to process aluminum parts is likely to cause thread loss, random buckles, or even tap breaks, resulting in scrapped workpieces. Secondly, pay attention to the difference between through-hole taps and blind-hole taps. The front end of the through-hole taps is guided longer, and the chip removal is the front chip removal. The leading end of the blind hole is shorter, and the chip removal is rear. For blind holes with through-hole taps, the thread processing depth cannot be guaranteed. Furthermore, if a flexible tapping chuck is used, the diameter of the tap shank and the width of the square should be the same as that of the tapping chuck; the diameter of the shank of the tap for rigid tapping should be the same as the diameter of the spring collet. In short, only a reasonable choice of taps can ensure precision CNC machining.

- CNC programming for tap processing

The programming of tap processing is relatively simple. Now the machining center generally solidifies the tapping subroutine, and only needs to assign each parameter. But it should be noted that, because the numerical control system is different, the format of the subroutine is different, and the meaning of some parameters is different. For example, for the SIEMEN840C control system, its programming format is G84 X_Y_R2_ R3_R4_R5_R6_R7_R8_R9_R10_R13_. Only these 12 parameters need to be assigned during programming.

large&complicate Hole Threads – Thread Milling Method

- Features of Thread Milling

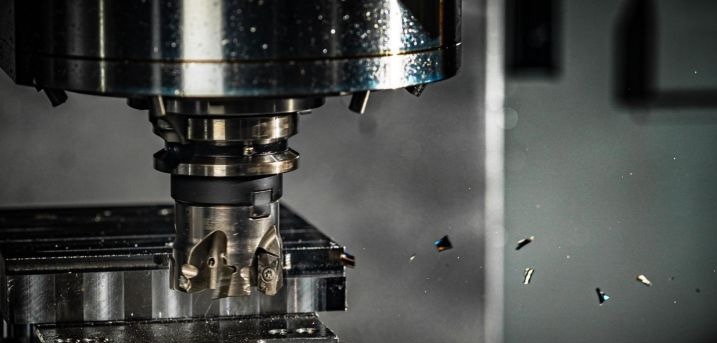

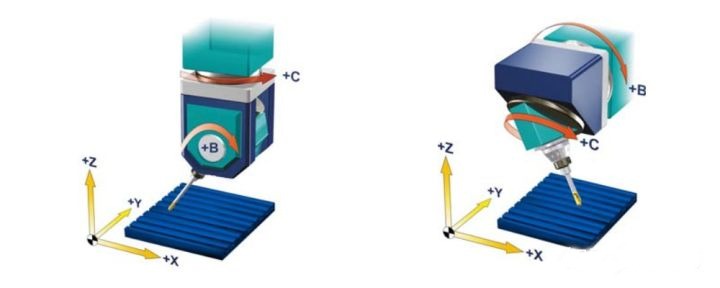

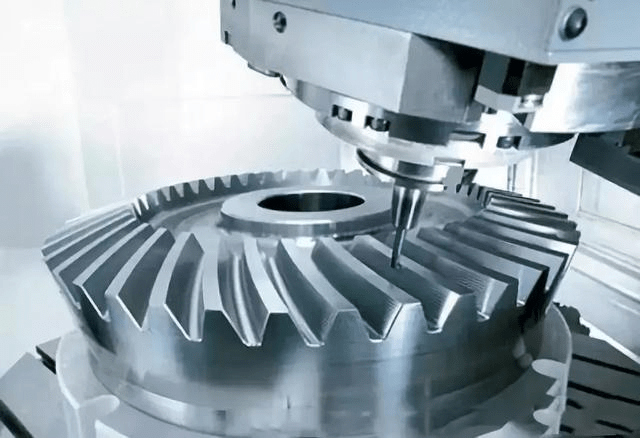

Thread milling is composed of a thread milling tool, a three-axis linkage of the machining center, that is, X, Y-axis circular interpolation, Z-axis linear feed milling method to process threads.

Thread milling is particularly used for the processing of large-hole threads and threaded holes of difficult-to-machine materials. It mainly has the next characteristics:

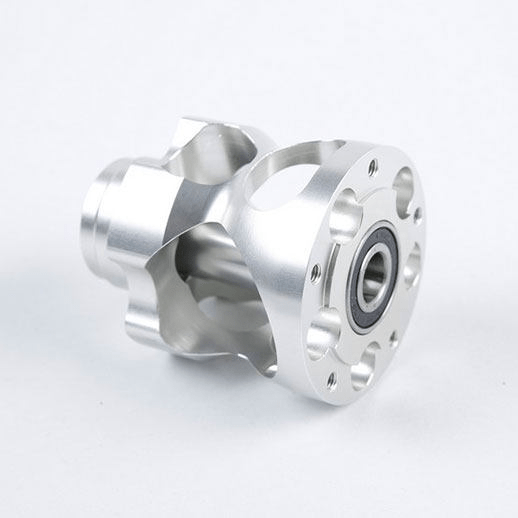

⑴ High processing speed, high efficiency, and high processing precision. The tool material is typically hard alloy material, and thus the cutting speed is fast. The manufacturing precision of the tool is high, therefore the thread precision of milling is high.

⑵ The range of milling tools is wide. As long as the pitch is that the same, regardless of whether it’s a left-handed thread or a right-handed thread, one tool is usually used, which is useful to chop the value of the tool.

⑶ CNC Milling processing is straightforward to get rid of chips and funky, and therefore the cutting performance is best than that of taps. it’s especially suitable for thread processing of aluminum, copper, chrome steel, and other difficult-to-machine materials.

It is especially suitable for the thread processing of huge parts and parts of precious materials, which may make sure the quality of thread processing and therefore the safety of the workpiece.

⑷ Because there’s no tooltip guide, it’s suitable for machining blind holes with short threaded bottom holes and holes without undercuts.

classification of Thread Milling Tools

CNC milling tools are often divided into two types, one is a machine-clamped cemented carbide blade milling cutter, and the other is an integral cemented carbide milling cutter. The machine clamp tool features a wide selection of applications. It can process holes with a thread depth but the length of the blade, or holes with a thread depth greater than the length of the blade. Integral cemented carbide milling cutters are generally won’t to machine holes whose thread depth is a smaller amount than the length of the tool.

CNC Programming for Thread Milling

The programming of thread milling tools is different from the programming of other tools. If the machining program is programmed incorrectly, it’s easy to cause tool damage or thread machining errors. concentrate on the subsequent points when compiling:

First of all, the threaded bottom hole should be machined, small diameter holes should be processed with a drill, and bigger holes should be boring to make sure the accuracy of the threaded bottom holes.

When the tool cuts in and out, the arc trajectory should be adopted, usually 1/2 circle for cutting in or out, and therefore the Z-axis direction should travel 1/2 pitch to make sure the thread shape. The tool radius compensation value should be brought in at this point.

X, Y-axis circular interpolation one circle, the spindle should travel a pitch along the Z-axis direction, otherwise, it’ll cause random threading.

A backup Thread Method – Pick-and-click method

Features of the pick method

Sometimes large threaded holes are often encountered on box parts. within the absence of taps and thread milling cutters, away almost like lathe picking is often used.