Copper and brass are two versatile metals commonly used in CNC machining due to their unique properties. Understanding the key differences between these materials is essential for selecting the appropriate one for your specific project. CNC expert JTR will explore the properties of copper and brass, their applications in CNC machining, and the factors to consider when choosing between the two.

Copper in CNC Machining

Copper is a highly versatile metal that is widely used in CNC machining due to its exceptional properties. Its combination of thermal conductivity, electrical conductivity, malleability, and machinability makes it an ideal choice for a variety of applications.

Thermal Conductivity

Copper is an excellent conductor of heat, meaning it can efficiently transfer heat from one point to another. This property is crucial in applications such as:

- Heat Exchangers: Copper is used to fabricate heat exchangers, which are devices that transfer heat between two fluids. Its high thermal conductivity ensures efficient heat transfer, making it a popular choice for applications like air conditioning, refrigeration, and industrial processes.

- Radiators: Copper is also used in radiators, which are devices that dissipate heat into the surrounding environment. Its thermal conductivity helps to quickly and effectively cool down hot fluids or components.

Electrical Conductivity

Copper is an excellent conductor of electricity, making it an essential material in the electrical industry. Some common applications include:

- Electrical Wiring: Copper is used to manufacture electrical wires and cables due to its low electrical resistance and high conductivity.

- Printed Circuit Boards (PCBs): Copper is a key component in PCBs, where it is used to create conductive traces that connect various electrical components.

- Electrical Connectors: Copper is used to fabricate electrical connectors, which are used to join electrical circuits together.

Malleability

Copper is a highly malleable metal, meaning it can be easily shaped and formed without breaking. This property makes it suitable for applications that require complex shapes or intricate designs, such as:

- Architectural Elements: Copper is used to create decorative architectural elements, such as roofing, cladding, and sculptures. Its malleability allows it to be formed into intricate shapes and patterns.

- Decorative Items: Copper is used to create a wide range of decorative items, including jewelry, tableware, and home decor accessories. Its malleability and ability to be polished to a high shine make it a popular choice for these applications.

Machinability

Copper is a relatively easy metal to machine, making it suitable for various CNC machining processes, including:

- Milling: Copper can be milled to create complex shapes and features.

- Turning: Copper can be turned to create cylindrical or conical components.

- Drilling: Copper can be drilled to create holes of various sizes and depths.

Brass in CNC Machining

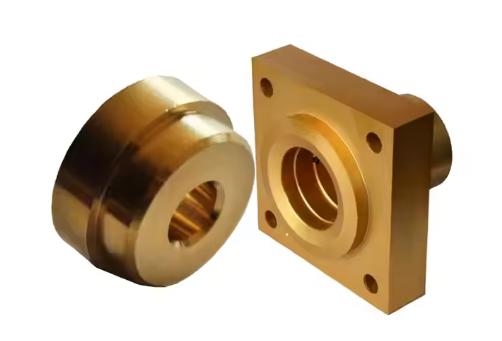

Brass is a copper alloy that is widely used in CNC machining due to its desirable properties. Its combination of strength, corrosion resistance, machinability, and aesthetic appeal makes it a popular choice for a variety of applications.

Strength

Brass is a relatively strong metal, offering good mechanical properties such as tensile strength and yield strength. This makes it suitable for applications that require components to withstand loads and stresses, such as:

- Hardware: Brass is commonly used to manufacture hardware components, such as doorknobs, hinges, and locks, due to its strength and durability.

- Plumbing Fixtures: Brass is a popular choice for plumbing fixtures, including faucets, valves, and pipes, because of its strength and resistance to corrosion.

Corrosion Resistance

Brass is naturally resistant to corrosion, making it an excellent choice for applications where the material will be exposed to harsh environments or corrosive substances. This resistance is due to the presence of zinc in the alloy, which forms a protective oxide layer on the surface of the brass.

Machinability

Brass is a relatively easy metal to machine, making it suitable for various CNC machining processes, including:

- Milling: Brass can be milled to create complex shapes and features.

- Turning: Brass can be turned to create cylindrical or conical components.

- Drilling: Brass can be drilled to create holes of various sizes and depths.

Aesthetic Appeal

Brass has a warm, golden color that is often desired for decorative applications. Its aesthetic appeal makes it a popular choice for:

- Musical Instruments: Brass is used to manufacture a variety of musical instruments, such as trumpets, trombones, and tubas. Its warm tone and durability make it an ideal choice for these applications.

- Decorative Items: Brass is used to create a wide range of decorative items, including home decor accessories, jewelry, and architectural elements. Its aesthetic appeal and durability make it a popular choice for these applications.

Key Differences Between Copper and Brass

| Property | Copper | Brass |

| Strength | Generally softer and weaker than brass | Stronger and harder than copper |

| Hardness | Relatively soft | Harder than copper |

| Machinability | Excellent machinability | Good machinability, slightly harder to machine than copper |

| Corrosion Resistance | Good corrosion resistance, especially in marine environments | Excellent corrosion resistance, often used in outdoor applications |

| Color | Reddish-brown | Golden-yellow |

Impact on CNC Machining and Final Product

- Strength and Hardness: Brass is generally a better choice for applications that require stronger and more durable components, such as hardware and plumbing fixtures. Copper, while softer, is still suitable for many applications, especially those that prioritize electrical conductivity or thermal conductivity.

- Machinability: Both copper and brass are relatively easy to machine, but brass may require slightly more effort due to its slightly higher hardness. The choice between copper and brass may depend on the specific machining operations involved and the desired tolerances.

- Corrosion Resistance: Brass is generally more resistant to corrosion than copper, making it a better choice for applications where the material will be exposed to harsh environments or corrosive substances. Copper is still reasonably resistant to corrosion, but brass offers superior protection.

- Color: The color of the material may be a factor in certain applications, especially those where aesthetics are important. Copper’s reddish-brown color and brass’s golden-yellow color can create different visual effects.

Both copper and brass are versatile materials with unique properties that make them suitable for various CNC machining applications. The choice between copper and brass will depend on the specific requirements of the project, including strength, hardness, corrosion resistance, machinability, and aesthetic preferences.

Choosing the Right Material for Your CNC Project

When selecting between copper and brass for your CNC project, consider the following factors:

| Functional Properties | Strength and Durability | If your project requires strong and durable components, brass is often a better choice. Copper is suitable for applications that prioritize electrical conductivity or thermal conductivity. |

| Corrosion Resistance | For applications exposed to harsh environments or corrosive substances, brass offers superior corrosion resistance. Copper is still reasonably resistant but may not be as suitable in extreme conditions. | |

| Electrical Conductivity | Copper is an excellent conductor of electricity, making it ideal for electrical components and applications requiring high conductivity. Brass is also conductive but not as efficient as copper. | |

| Thermal Conductivity | Copper is a better conductor of heat than brass, making it a good choice for applications that require efficient heat transfer, such as heat exchangers or radiators. | |

| Aesthetic Preferences | Color | Copper has a reddish-brown color, while brass has a golden-yellow color. Choose the material based on the desired aesthetic appearance of your final product. |

| Patina | Both copper and brass can develop a patina over time, which can add a unique aesthetic quality. Consider whether you prefer the patina of copper or brass for your project. | |

| Cost Considerations | Material Cost | Copper and brass have varying costs depending on market conditions and availability. Consider your budget and compare the costs of the two materials. |

| Machining Costs | Machinability can also impact costs. While both copper and brass are relatively easy to machine, slight differences in hardness can affect machining times and costs. | |

| Machinability Factors | Tool Wear | The hardness of the material can affect tool wear. Brass, being slightly harder, may cause slightly more tool wear compared to copper. |

| Surface Finish | Both copper and brass can achieve excellent surface finishes with proper machining techniques. Consider the desired surface finish for your project. |

Making the Right Material Choice

Copper and brass are both valuable materials for CNC machining, with each having unique advantages. You can make an informed decision about whether to use copper or brass by taking into account factors such as strength, corrosion resistance, machinability, aesthetic appeal, and project-specific requirements. Consult the CRelated ArticlesNC machining service supplier JTR to make the right decision that will ensure that your CNC project meets your expectations and produces optimal results.