In recent years, China’s CNC machining technology has become increasingly mature and has gradually become one of the world’s leading countries in CNC machining technology. At the same time, due to the continuous increase in infrastructure construction in China in recent years, the demand for sheet metal fabrication in China is also gradually rising. This article will comprehensively introduce the development of sheet metal fabrication in the Chinese market.

What is sheet metal processing or sheet metal fabrication?

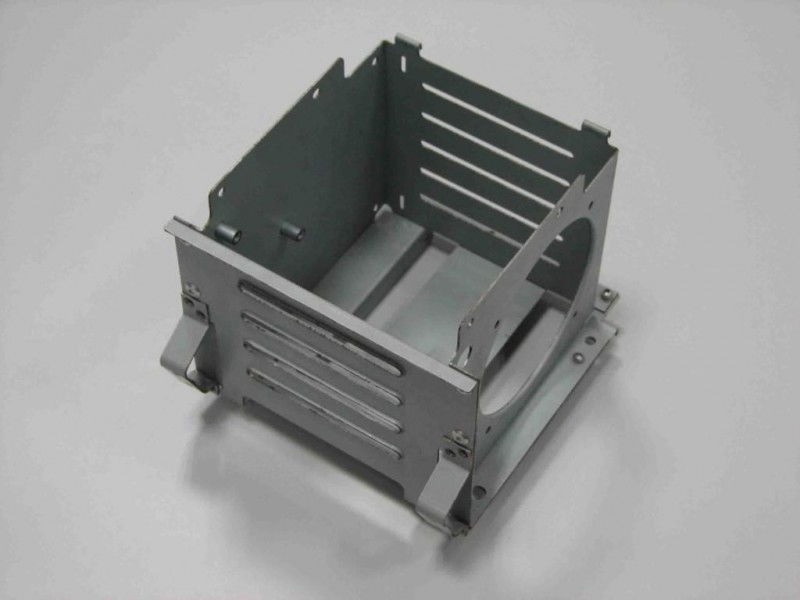

Sheet metal fabrication is a kind of metal processing technology, which usually refers to a comprehensive cold deformation processing technology for metal sheets, including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming, etc., the thickness of the metal sheet does not change. The metal processing processes corresponding to the sheet metal process include casting, forging, machining, etc., and the metal thickness of its products is usually inconsistent.

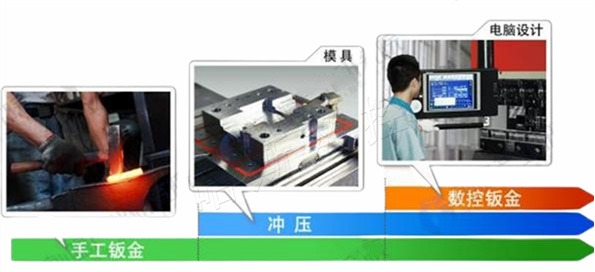

According to the different processing methods, the sheet metal process is divided into manual sheet metal, stamping, and CNC sheet metal. At present, manual sheet metal is mainly concentrated in the fields of auto repair, art, advertising, etc.; stamping sheet metal is suitable for products with a single variety, large output, small structure, and relatively stable product; CNC sheet metal is suitable for small batches and varieties. Variety of products and sizes.

Beginning with bronze and iron wares in ancient times, people used various methods to smelt metal materials. With the improvement of smelting technology, they gradually smelted metal plate-like materials and learned to use some tools to process these metal plate-like materials. This is the prototype of sheet metal technology.

The history of modern sheet metal technology is not long. The application of stamping equipment and cold stamping dies in the field of sheet metal processing, and the popularization of CNC automation equipment are two milestones in the development of sheet metal technology. The former gave birth to stamping, and the latter gave birth to CNC sheet metal.

Sheet metal fabrication industry chain

The main raw materials of the sheet metal processing industry are non-ferrous metal alloy plates and thin steel, and the non-ferrous metal industry and steel industry account for about 40% of the total industry cost. In addition, processing raw materials into sheet metal products requires forging machinery and molds. Therefore, the above four industries are upstream of the sheet metal processing industry.

Due to the wide range of application fields of sheet metal products, its downstream includes almost all manufacturing industries, mainly the communication electronics industry, automobile manufacturing, motorcycle manufacturing, aerospace industry, instrumentation industry, home appliance industry, etc. Generally speaking, most of the metal forming parts of various electromechanical products are produced by sheet metal process. Among them, the stamping process is suitable for mass production, while the CNC sheet metal process is suitable for precision production.

Status Quo of China’s Sheet Metal Processing Industry

Market Status of Sheet Metal Processing

With the expansion of the global economy and industrial adjustment, since the 1980s, the global manufacturing industry has accelerated its transfer to emerging markets such as Asia and Latin America. At present, China has become an important base for the world’s manufacturing industry. The rapid development of the manufacturing industry and the huge market capacity of industrial products have driven the development of my country’s sheet metal processing industry, and the market demand for sheet metal processing products in my country is very strong.

From 2011 to 2020, the market scale of China’s sheet metal processing industry continued to expand; in 2016, the market size of China’s sheet metal processing industry reached 688.5 billion yuan. But in general, the sheet metal processing industry started late, the scale of the industry is generally small, and there is a lack of production and technical personnel. The core competitiveness of enterprises is difficult to form, and the market competition is becoming increasingly fierce.

Economic benefits of sheet metal processing industry

At present, on the whole, the economic benefits of sheet metal processing in China are relatively good, and the operating profits of many industrial enterprises are above 20%. The sheet metal processing industry mainly provides distribution and processing for automobiles, shipbuilding, precision machine tools, precision instruments, communication electronics, and elevators.

Most of the partners are large foreign companies (GE, BOSCH, OTIS). With the further deepening and lasting of the cooperative relationship, they learn advanced technology, technology, and strict and standardized production environment, production process, and other aspects. Management experience, so that key components and key technologies can be gradually localized, which accordingly reduces the purchase of key components by foreign-funded enterprises from abroad, and reduces the production cost of manufacturing enterprises.

As China becomes more and more an international processing and manufacturing center, the demand for metal processing capabilities continues to increase, and electrical control boxes and machine casings in the metal processing industry are generally sheet metal parts, so the demand for sheet metal processing capabilities also increases. Continuous improving.

In addition, as far as sheet metal processing is concerned, sheet metal processing enterprises usually need a variety of mechanical equipment to meet different process requirements, while sheet metal punching accuracy is generally around ±0.1mm, and bending accuracy can generally reach ±0.5mm, so the accuracy is much lower than that of sheet metal processing.

Therefore, the advancement of industrial technology has also brought high profits. For example, the profit margin of stamping in sheet metal processing can generally reach about 30%, and the profit of laser cutting is as high as 50% or more.

After 2022, how will China’s sheet metal processing develop?

Overall, the profit level of the sheet metal processing industry mainly depends on product quality and processing accuracy, products and value-added services, downstream user enterprises, and upstream raw material prices.

Therefore, as the technical content of products in the industry becomes higher and higher, the impact of fluctuations in raw material prices on products is gradually weakened, and the trend of changes in industry profit levels continues to improve.

At the same time, the changing trend of future profit levels mainly depends on factors such as product quality and precision, product value-added services, and downstream customer industries. Enterprises with strong technical strength, high-end customer resource advantages, and management advantages in the industry will obtain higher profit levels in the industry in the fierce competition in the future.