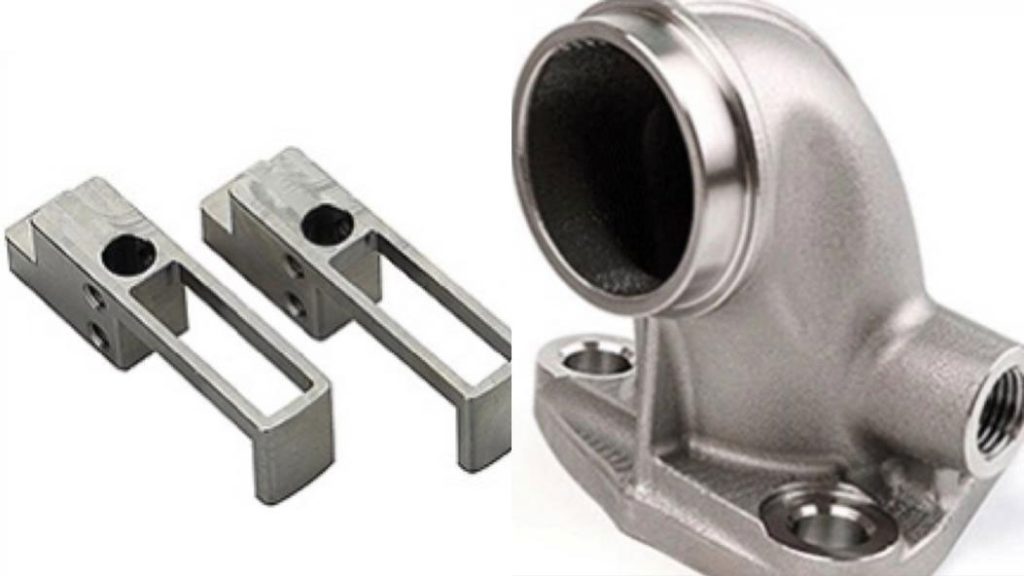

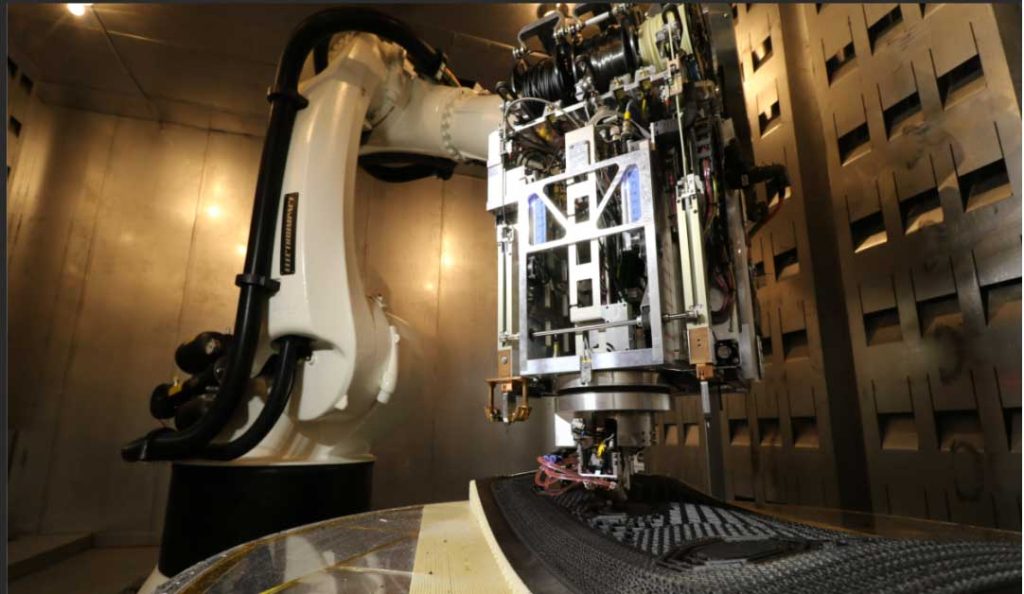

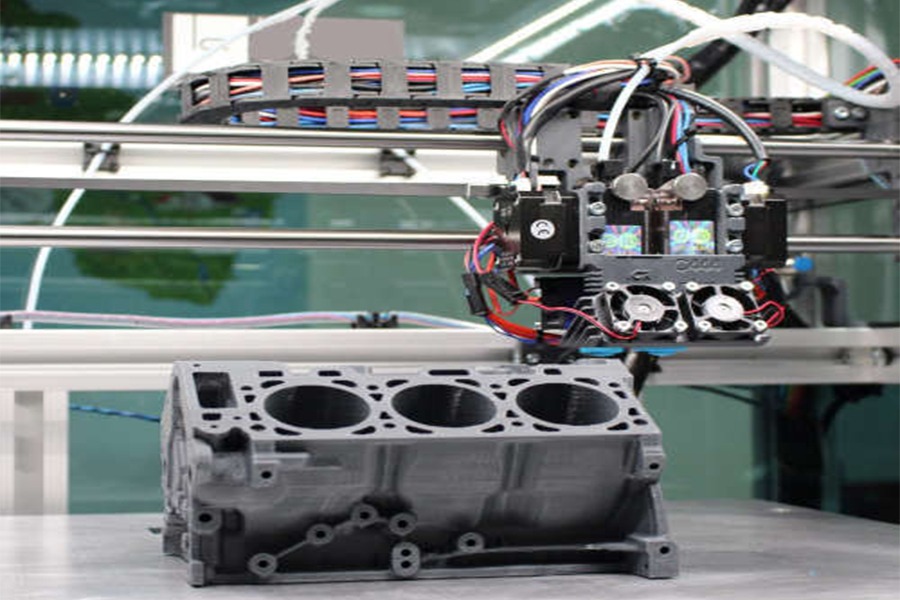

What we call 3D printing is usually used in mold manufacturing, industrial design, and other fields. In addition, in the field of food, 3D printing technology has also made some important developments.

Advantages of 3D Printing

1. The operation is simple and convenient

The manufacturing process of traditional lathes requires operators to learn operation methods and techniques for a long time. However, 3D printing only needs to know the operation of the computer software and the calibration of the machine, and the complete operation process can be mastered without long-term study. Compared with the traditional lathe manufacturing process, it will be much simpler.

2. Improve production efficiency

Manufacturing corresponding products through 3D printing technology can achieve rapid production, improve production efficiency, and shorten manufacturing time.

3. Cost-saving

3D printing is an additive process, while the traditional lathe manufacturing process is a subtractive process. The consumption of raw materials is minimized. It has changed the phenomenon of serious waste of scraps in traditional metal and plastic manufacturing.

What is Food 3D Printing?

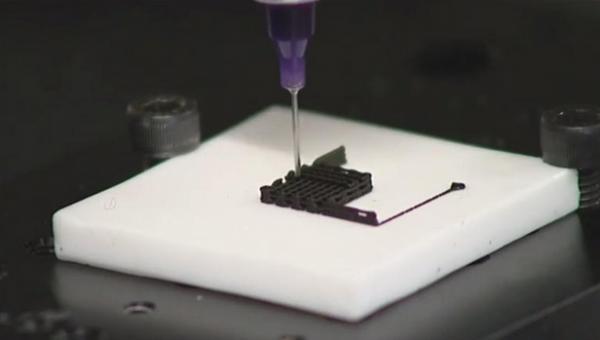

3D food printing is to “print” food through a 3D food printer. By putting food ingredients or ingredients in the container in advance, then entering the recipe, and pressing the switch, the rest of the cooking process will be done by it, and real food will be made.

Through 3D printing, food can be customized in batches through technical means, including food taste and nutritional content.

The Development of Food 3D Printing

Traditional cooking tools, including knives, frying pans, etc., have low precision and cannot process complex and changeable shapes. If 3D food printers are used to print food and digital recipes, they can process flavors and shapes that cannot be achieved in traditional cooking, opening a new chapter in the field of food cooking.

Advantages of 3D Food Printing

1. Simple operation and improved efficiency

Compared with manual operation, machine operation can greatly improve work efficiency. If it is used to make staple food, it can be eaten with only a small amount of processing based on the 3D printed product, which is very convenient.

2. Save raw materials

As additive manufacturing, food 3D printing minimizes the cost of raw materials.

3. Personalized customization

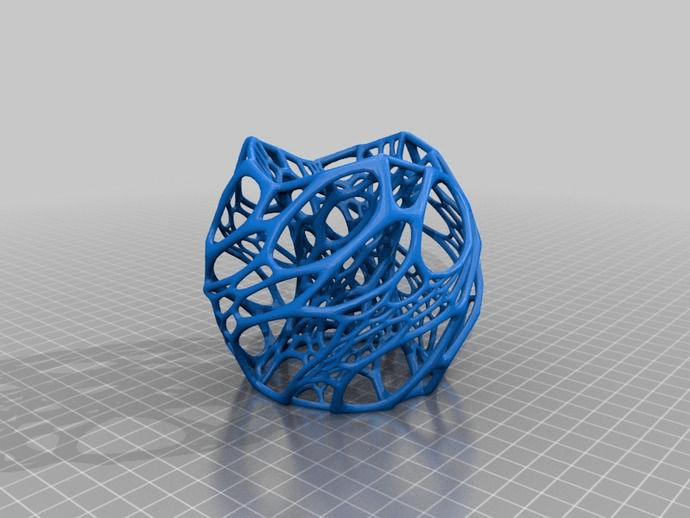

The biggest feature of 3D printing is that it can be customized at a low cost, eliminating the need for expensive molds. It can be molded at one time as long as the appropriate material is selected. Accurately quantified food can be obtained through 3D printing, which is especially suitable for diabetics or those who lose weight and have special dietary requirements. It is also suitable for making complex and high-precision food. Compared with manual work, the machine has higher precision and can easily achieve some shapes or shapes that are difficult to cook by hand.

4. Easy for long-term storage

3D printing food printing can perform high-concentration, fully enclosed compression preservation of basic food units such as chocolate, protein, carbohydrates, and meat cells.

5. It is not limited by the environment and can be manufactured remotely

3D printing does not require a special environment and venue. As long as there are raw materials, they can be printed according to the drawings. It can even be operated remotely from a computer.

The Current State of 3D Food Printing

1. Printing of meat

Meat printed from raw materials such as sugar, protein, fat, and muscle cells has a texture and taste similar to real meat. When printing fresh meat, it is printed from the inside out. First, a three-dimensional frame of a tiny piece of meat is constructed with artificial blood vessels, and the meat cell units are printed layer by layer around this frame. Fat and protein are then filled between the blood vessels to form muscle fibers and muscle tissue. The meat will expand from the inside out to the desired shape.

2. Printing of desserts

Using sugar, water, and alcohol as raw materials for 3D printing tastes sweet and fruity. At present, companies have printed candy and chocolate with raw materials such as sugar, chocolate, and cream, and these printed products are mainly for high-end dessert shops.

3. Raw materials for 3D food printing

There are many food materials and types that can be printed by carbohydrates, such as starch, rice flour, biscuits, mashed potatoes, purple potato mash, bean paste, jams, honey, carrageenan, pectin, etc.

Fatty ingredients that can be used for 3D printing include chocolate, cheese, butter, cream, etc. Among them, chocolate is a typical and widely used printable food material.

Protein food materials that can be used for 3D printing include gelatin, concentrated milk protein, insect protein, microalgae protein, soy protein, etc.

Future Applications of 3D Food Printing

In the future, with the continuous development of 3D food printing, this technology may be able to solve the food crisis facing the world and also make food for astronauts in space.

Conclusion

JTR is a company that provides 3D printing services for rapid prototyping and small-batch production. We have also been paying attention to the development of 3D printing technology in different fields and have been committed to learning and improving our abilities to provide you with better services.