Stainless steel is a popular material known for its excellent corrosion resistance. But with various grades available, choosing the right one for your project can be crucial. Two common austenitic stainless steel grades, SS304 and SS321, often cause confusion due to their similarities. This article explores the key differences between SS304 and SS321 to help you make an informed decision.

Similarities of SS304 and SS321

Despite their differences, SS304 and SS321 share several similarities, making them both popular choices in various applications. Several common properties include:

Chemical Similarities

- Base Material: Both SS304 and SS321 are austenitic stainless steels, characterized by their face-centered cubic crystal structure, which provides good mechanical properties and ductility.

- Primary Alloying Elements: Both grades primarily consist of iron, chromium (18-20%), and nickel (8-10.5%), which give them good corrosion resistance and overall strength.

- Corrosion Resistance: Both SS304 and SS321 offer excellent resistance to a wide range of atmospheric environments and many corrosive media, including acetic acid, citric acid, formic acid, tartaric acid, and sulfurous acid.

- Heat Resistance: Both can be used in applications with temperatures up to about 870°C (1600°F), though SS321 has a slight edge at higher temperatures due to its titanium stabilization.

Physical Similarities:

- Non-Magnetic: Generally non-magnetic in the annealed condition, both grades might become slightly magnetic when cold worked.

- Weldability: Easily weldable by most conventional welding processes such as TIG, MIG, and resistance welding, neither grade typically requires pre- and post-welding treatments.

- Mechanical Properties: Both grades have similar mechanical properties, such as tensile strength and yield strength, making them suitable for similar applications.

- Formability: Both SS304 and SS321 have good formability, allowing them to be easily shaped into various forms without cracking or breaking.

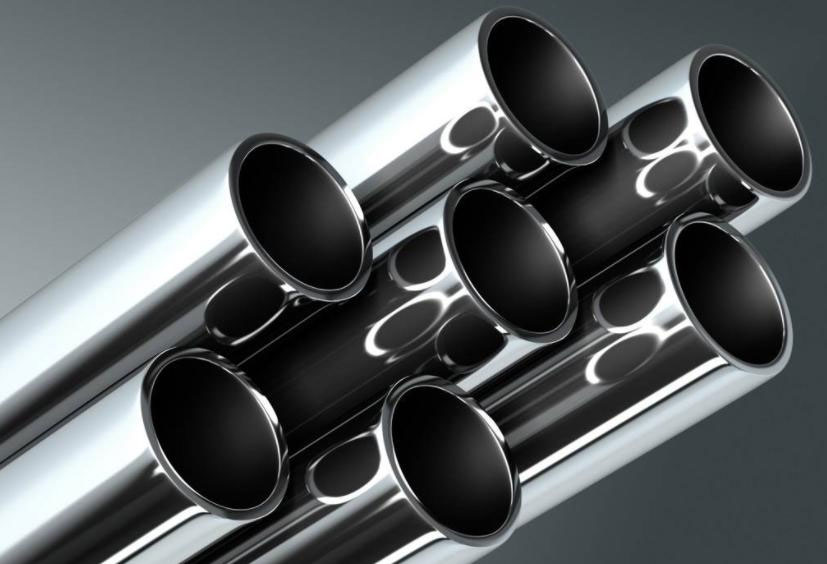

- Surface Finish: Both grades can achieve similar surface finishes, which can be polished or brushed to achieve a desired aesthetic or functional property.

- Applications: Commonly used in the food and beverage industry, chemical processing, oil and gas industry, and various industrial applications requiring good corrosion resistance and formability.

Understanding these similarities helps recognize why both SS304 and SS321 are widely used and often considered for similar applications, despite their differences.

3 Key Differences between SS304 and SS321

While they share many similarities, a crucial difference lies in their chemical composition:

1. Chemical Composition:

SS321 introduces a small amount of titanium (Ti) into the mix, typically exceeding five times the carbon (C) content. This addition makes SS321 a “stabilized” grade. In contrast, SS304 does not contain titanium.

This seemingly minor difference significantly impacts their performance at high temperatures:

2. High-Temperature Performance:

SS304: At elevated temperatures, carbon in SS304 can combine with chromium to form chromium carbides. These carbides precipitate at grain boundaries, depleting chromium in those areas and reducing corrosion resistance. This phenomenon, known as carbide precipitation, can lead to intergranular corrosion and reduced mechanical strength.

SS321: The presence of titanium in SS321 prevents this issue. Titanium has a higher affinity for carbon compared to chromium. It preferentially bonds with carbon, forming stable titanium carbides instead of chromium carbides. This maintains chromium’s distribution throughout the steel, ensuring better corrosion resistance and superior high-temperature strength.

3. Applications:

SS304 Parts: Due to its susceptibility to carbide precipitation, SS304 parts is generally limited to applications with moderate temperatures, typically below 1472°F (800°C). It’s a popular choice for kitchen sinks, architectural panels, and general-purpose applications where good corrosion resistance and formability are priorities.

SS321 Parts: On the other hand, SS321’s resistance to carbide precipitation makes it the preferred choice for high-temperature environments. Its applications include exhaust systems, boilers, heat exchangers, chemical processing equipment, and other components exposed to sustained elevated temperatures.

Conclusion

SS304 and SS321 are both versatile austenitic stainless steels. They offer excellent corrosion resistance, good formability, and weldability. However, the addition of titanium in SS321 makes it a superior choice for high-temperature applications due to its enhanced resistance to carbide precipitation. When selecting between SS304 and SS321, consider the specific requirements of your project, particularly the operating temperature.

JTR is a professional CNC machining service provider in China. Any materials like aluminum, brass, stainless steel, plastic or others can be machined. No matter you want to customize or machining your parts, they will providing you reliable service. Feel free to contact them when you need.