Metal surfaces are prone to corrosion, scratching, and other forms of damage. To protect them, various finishing techniques are employed, with spray painting and powder coating being two of the most popular options. Each method has its unique characteristics, advantages, and disadvantages. This article will delve into the intricacies of spray painting and powder coating, comparing and contrasting their attributes to help you determine which one is better suited for protecting your metal surfaces.

What is Spray Painting?

Spray painting involves applying a liquid paint to a surface using a spray gun, allowing for a smooth, even coat. The paint is composed of pigments, solvents, and binders that adhere to the metal surface when sprayed, creating a protective layer.

Types of Spray Paints

- Acrylic Paint: Known for its fast drying time and resistance to weathering. It’s a popular choice for outdoor applications.

- Enamel Paint: Provides a hard, glossy finish, making it suitable for items that require durability, such as machinery or vehicles.

- Epoxy Paint: Offers high adhesion and resistance to chemicals and moisture, making it ideal for metal surfaces exposed to harsh environments.

Benefits of Spray Painting

- Versatility: Spray paint can be applied to a variety of surfaces, including complex shapes and large metal structures.

- Cost-Effective for Small Projects: For small-scale applications, spray painting is often more affordable due to lower material and equipment costs.

- Customizable: Offers a wide range of colors and finishes (glossy, matte, satin) to meet aesthetic needs.

Spray painting is a versatile and cost-effective option, particularly suited for small projects and those requiring custom finishes. However, its durability may not match other coating techniques.

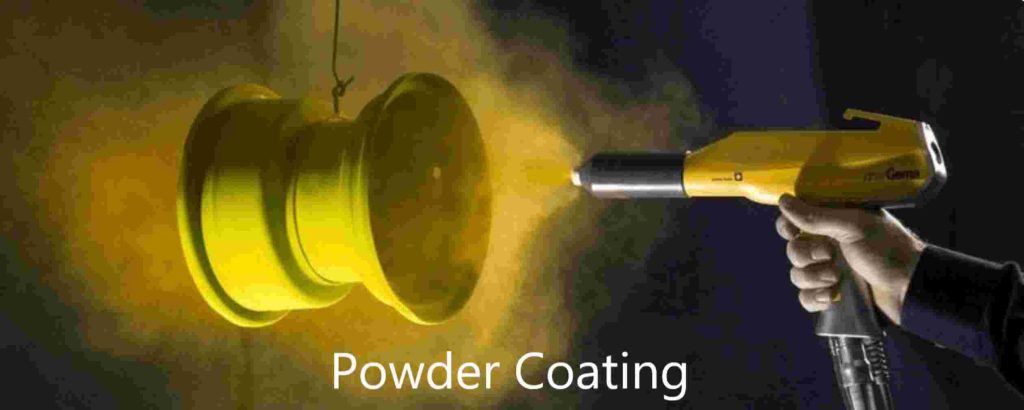

What is Powder Coating?

Powder coating is a dry finishing process in which a powder composed of finely ground resin and pigment is electrostatically applied to the metal surface. The coated surface is then heated in a curing oven, causing the powder to melt and form a hard, durable finish.

Types of Powder Coating

- Thermoplastic: This type of powder can melt and reform multiple times, providing flexibility and impact resistance. It is often used in automotive parts and heavy-duty metal objects.

- Thermoset: Once cured, thermoset powder coating forms a permanent, inflexible finish that offers superior heat and chemical resistance, commonly used in appliances and industrial equipment.

Benefits of Powder Coating

- High Durability: Powder coating provides a tough, chip-resistant finish, ideal for surfaces exposed to heavy wear or harsh conditions.

- Environmentally Friendly: Powder coating emits no volatile organic compounds (VOCs) and generates less waste compared to spray painting.

- Consistent, Thick Layer: The electrostatic application allows for a uniform layer of coating even on complex shapes.

Powder coating is well-suited for projects requiring a highly durable and environmentally friendly finish, especially for larger, industrial applications.

5 Differences Between Powder Coating and Spray Painting

1. Durability and Protection Comparison

Spray Painting: While spray paints, especially epoxy types, can provide good resistance to moisture and UV light, they may require regular maintenance or recoating due to chipping, fading, or corrosion over time. Their protective qualities are more suited to moderate conditions.

Powder Coating: Powder coating offers superior durability. Its thick, even layer is resistant to scratches, chipping, and corrosion. The curing process ensures a long-lasting finish, making it ideal for metal surfaces exposed to extreme weather, chemicals, or heavy use.

For maximum protection against wear, corrosion, and harsh environments, powder coating is the better option.

2. Application Process: Ease and Efficiency

Spray Painting: The application process for spray painting is relatively simple and requires minimal setup, making it suitable for small or intricate projects. However, achieving an even coat requires skill, and the drying time can vary based on the paint type.

Powder Coating: Powder coating requires specialized equipment, including an electrostatic sprayer and curing oven, which makes it more complex and less accessible for small-scale or DIY projects. However, the curing process is faster than drying liquid paint, leading to quicker project completion for large-scale applications.

Spray painting offers ease of use for smaller, detailed projects, while powder coating, though more equipment-intensive, provides efficiency for large-scale operations.

3. Aesthetic Appeal: Appearance and Finishing

Spray Painting: Offers more flexibility in terms of colors, textures, and finishes, such as high gloss, satin, or matte. However, the finish may wear off or fade more quickly under harsh conditions.

Powder Coating: Though color options are more limited compared to spray paint, powder coating provides a smoother and more durable finish. It resists fading and retains its appearance over time, making it ideal for surfaces that need to maintain their aesthetic appeal long-term.

For long-term aesthetic durability, powder coating outperforms spray painting, though spray painting provides more flexibility in finish and color options.

4. Environmental Impact and Safety

Spray Painting: The solvents in spray paints often release volatile organic compounds (VOCs) into the air, contributing to environmental pollution. Additionally, spray painting produces overspray, leading to waste.

Powder Coating: Powder coating is an environmentally friendly process, producing no VOCs and minimizing waste since the unused powder can be recycled. Additionally, the process is safer for workers, as it doesn’t require harmful solvents.

Powder coating is the more eco-friendly and safer option, particularly for industrial applications.

5. Cost Considerations

Spray Painting: For small-scale projects, spray painting is generally more cost-effective due to the lower cost of materials and equipment. However, it may require more frequent maintenance and recoating, increasing long-term costs.

Powder Coating: While the initial setup cost for powder coating is higher, the long-lasting protection it offers can reduce the need for recoating and maintenance over time, making it more cost-effective for large projects.

Powder coating has a higher upfront cost but is more economical over the long term, especially for projects requiring extensive durability.

For Metal Protection: When to Choose Each

The choice between spray painting and powder coating depends on various factors, including the type of metal, desired level of protection, aesthetic requirements, and environmental considerations. Here are some suggestions:

| Spray Painting or Powder Coating | When to Choose |

| Choose Spray Painting | For small-scale projects, intricate or detailed work, and when customization in color and finish is a priority. It’s also suitable for projects where initial costs need to be kept low and durability is not a top concern. |

| Choose Powder Coating | For large-scale projects, industrial applications, or metal surfaces exposed to heavy use or harsh environments. It offers superior protection, durability, and environmental benefits, making it the preferred choice for projects where long-lasting performance is critical. |

For projects that require long-lasting protection and durability, powder coating is the clear winner. For more budget-friendly, customizable finishes, spray painting remains a practical option. Please make the decision based on your specific needs of the project. If you need some suggestions, please feel free to contact us.