Die casting is a metal casting process, which characteristic is to apply high pressure to molten metal by using a mold cavity. And molds are usually machined from stronger alloys. The process is similar to injection molding. To let people have a comprehensive understanding of die casting, JTR company has organized and summarized what die casting is? What is the process of die casting? What are the materials of die casting? And other questions, I hope you can have a full understanding of “die casting“.

Definition of “Die Casting”

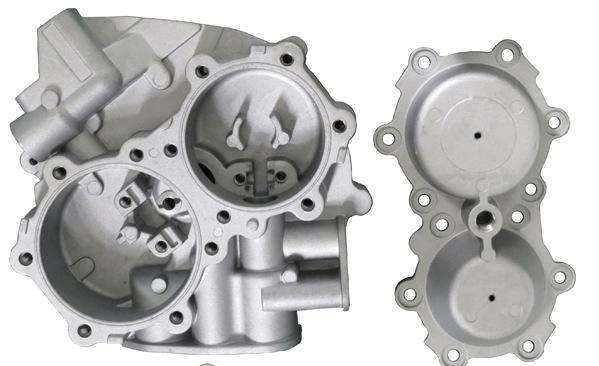

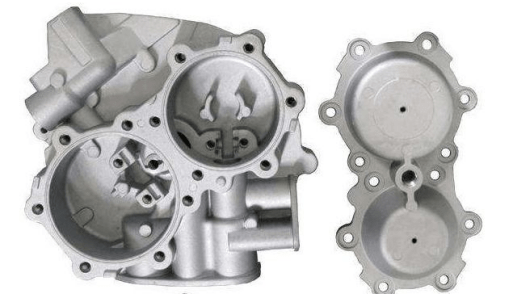

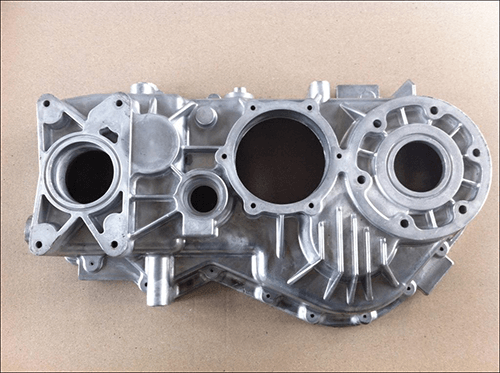

Die casting is an accuracy casting technique that makes use of high stress to require molten metal into a metal mold and mildew with intricate shapes. Spreadings made by die-casting are called die castings.

Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and also their alloys. Relying on the sort of die casting, a cool chamber die casting device or a warm chamber die casting device is required.

The tensile strength of these materials is nearly double that of ordinary cast alloys, which has more positive significance for aluminum alloy automobile wheels, frames, and other parts that are expected to be produced with higher strength and impact-resistant materials.

Die Casting Process

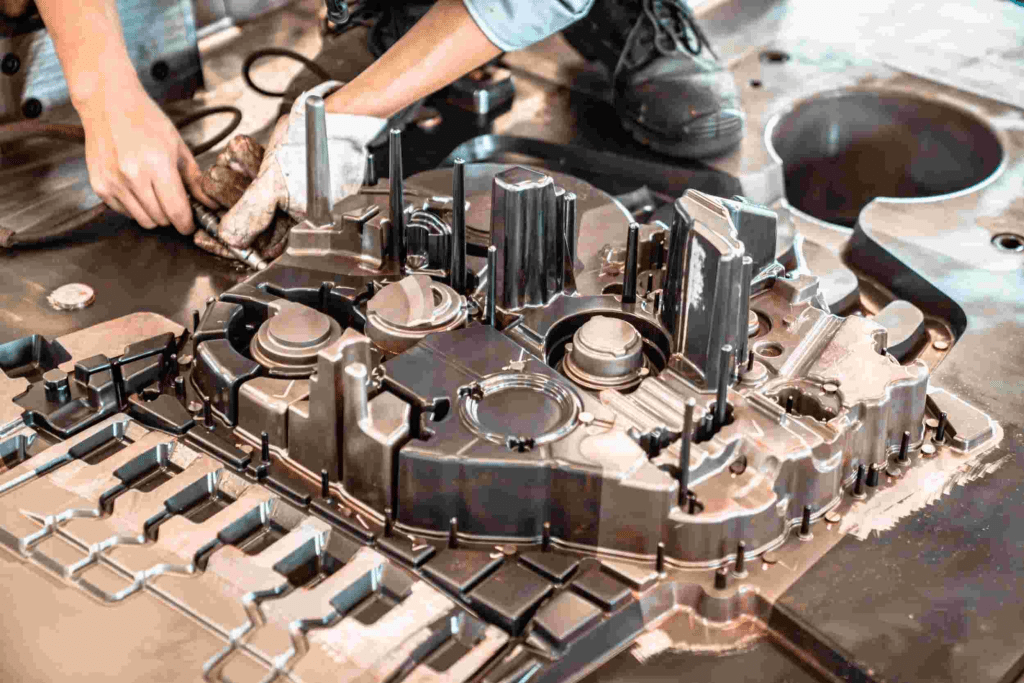

The typical die casting process mainly consists of 4 steps, or high pressure die casting. These four steps, including mold prep work, material filling, injection, and shakeout, are also the basis for various customized die casting processes.

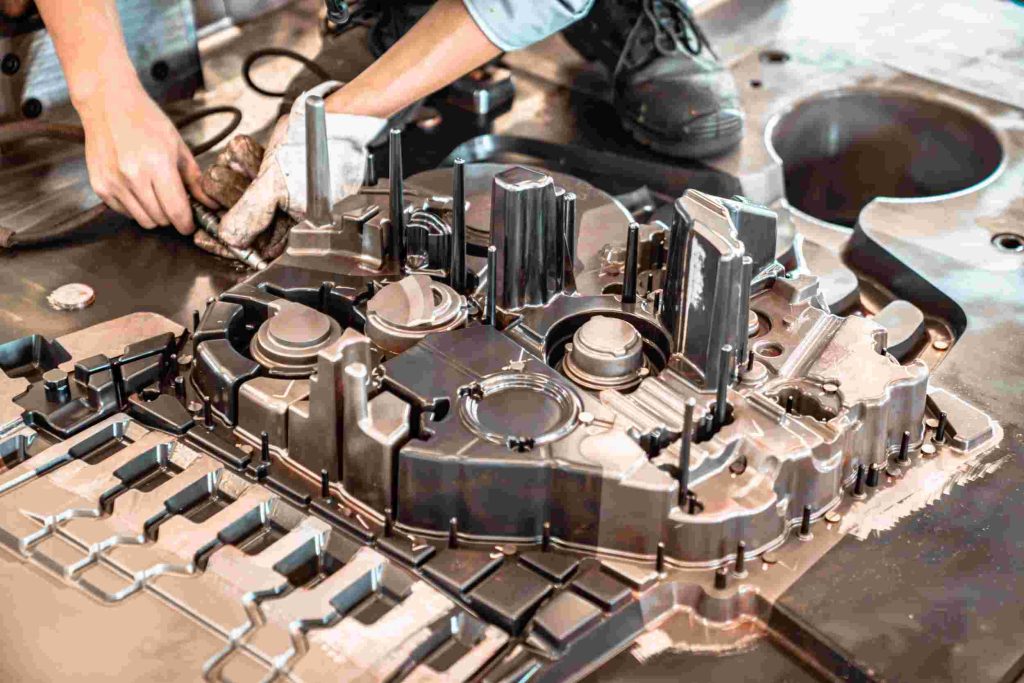

Lubricant is sprayed into the mold cavity throughout the preparation procedure. Along with helping to manage the temperature level of the mold, the lube can likewise assist the casting release. The mold can then be shut, and also the molten metal infused into the mold at high pressure, which varies from concerning 10 to 175 MPa.

After the molten metal is filled up, the pressure is maintained till the casting solidifies. The press pole after that pushes out all the castings, and also, because there may be several cavities in a mold, there may be multiple castings per casting.

The falling sand’s process needs the separation of residues, including mold openings, runners, gates, and flash. The process is usually done by squeezing the casting through a special trim die. Other ways of falling sand include sawing and sanding. If the gate is fragile, you can beat the casting directly, which can save human resources. Excess casting die can be reused after melting.

High-pressure injection results in very fast filling of the mold so that the entire mold can be filled with molten metal before any part solidifies. In this way, even thin-walled parts that are difficult to fill can be filled sufficiently, and surface discontinuities of the die-cast part can be avoided.

However, this additionally causes air entrapment, as it is hard for air to run away when filling the mold quickly. Placing vents on the parting line can lower this trouble, but really exact processes can also leave porosity in the casting center. After most parts are die-cast, they can be processed by Surface Finishing Service to complete some structures that cannot be completed by casting, such as drilling and polishing.

Defects can be inspected after the shakeout is complete. The most common defects include stagnation (insufficient filling of the solution). These flaws can be brought on by inadequate mold or molten metal temperature level, metal contamination, as well few vents, excessive lubricant, etc. Other problems consist of porosity, shrinking, thermal splitting, and also flow marks. Flow marks are marks left on the casting surface by gate defects, sharp corners, or excess lubricating substance.

Metal for Die Casting

Metals made use of in die casting mostly include zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys, although die casting is rare but viable. A lot more unique die-casting steels consist of ZAMAK, aluminum-zinc alloys, as well as American Aluminum Association standards: AA380, AA384, AA386, AA390, as well as AZ91D magnesium. The characteristics of die casting of numerous metals are as complies with:

Zinc: The easiest metal to die-cast, cost-effective to make small components, easy to coat, high compressive strength, plasticity, and durable life.

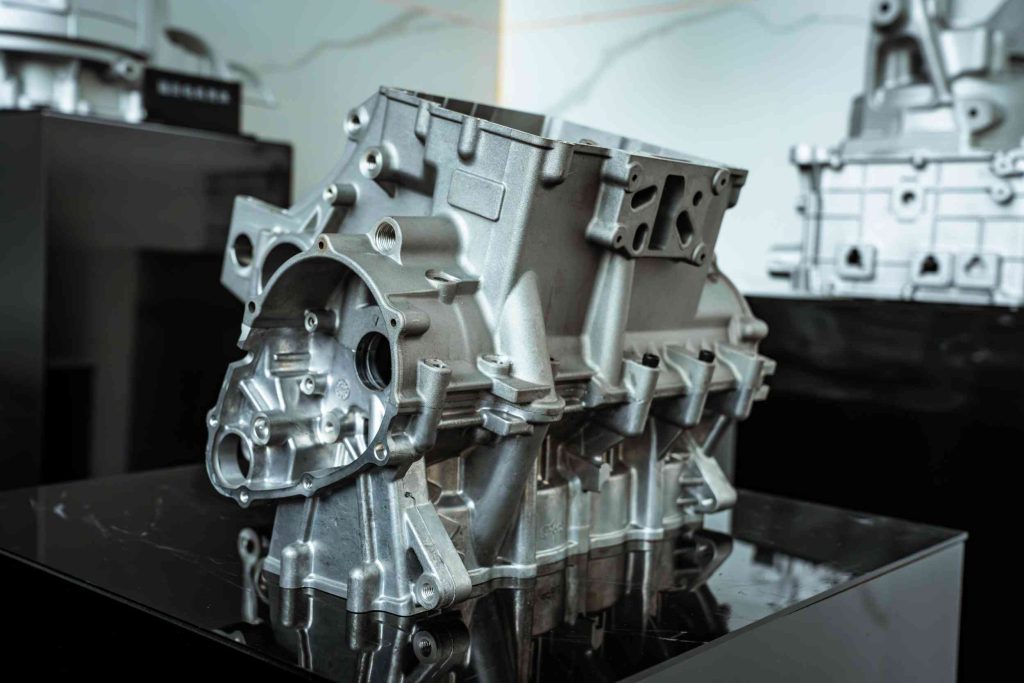

Aluminum: Lightweight, high dimensional stability while making complex and thin-walled castings, strong corrosion resistance, good mechanical properties, high thermal and electrical conductivity, and high strength at high temperatures

Magnesium: Easy to machine, high strength-to-weight ratio, lightest among commonly used die-cast metals

Copper: High hardness, strong corrosion resistance, the best mechanical properties of commonly used die-casting metals, wear resistance, and strength near to steel.

Lead and Tin: High density and extremely high dimensional precision can be used as special corrosion protection components. For public health reasons, this alloy cannot be used in food processing and storage equipment. Alloys of lead, tin, and antimony (sometimes with a little copper) can make hand lettering in letterpress printing and bronzing.

| Metal | Minimum cross-sectional area | Minimum draft angle |

| Aluminum alloy | 0.89 mm (0.035 in) | 1:100 (0.6°) |

| Brass and Bronze | 1.27 mm (0.050 in) | 1:80 (0.7°) |

| Magnesium alloy | 1.27 mm (0.050 in) | 1:100 (0.6°) |

| Zinc alloy | 0.63 mm (0.025 in) | 1:200 (0.3°) |

The upper mass limits for die casting with aluminum, copper, magnesium, and zinc are 70 lbs (32 kg), 10 lbs (4.5 kg), 44 lbs (20 kg), and 75 lbs (34 kg), respectively.

Advantages and Disadvantages of Die Casting

Advantages of die casting

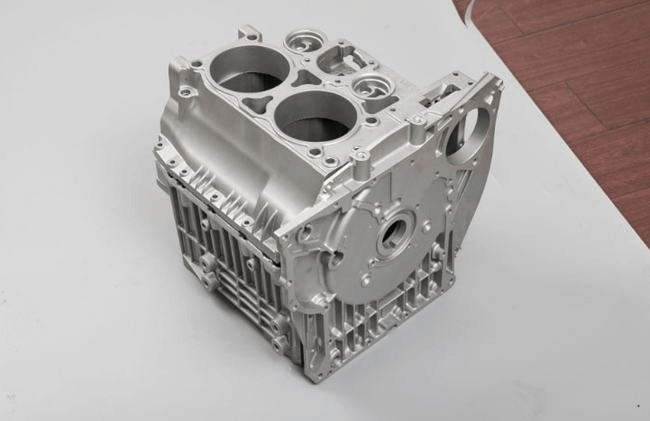

The advantages of die casting include that castings can have excellent dimensional accuracy.

Usually, this depends on the casting material. Compared to other casting processes, die casting produces parts with smooth surfaces and a fillet radius of approximately 1-2.5 microns. Die casting can produce parts with wall thicknesses of about 0.75 mm, compared to a flask or permanent mold castings. It can directly cast parts of internal structures, such as wire jackets, heating elements, high-strength bearing surfaces. Other benefits include reducing or avoiding secondary machining of parts, the production speed of castings, the tensile strength of castings (strength up to 415 MPa), and the ability to cast high-flow metals.

Disadvantages of die casting

The biggest disadvantage of die casting is its high cost. The price of die casting equipment (die-casting machines) and molds and mold-related components is relatively high compared to other casting methods. Therefore, die-casting manufacturing has high economic value only when mass-producing parts.

Other disadvantages include: the die casting process is only suitable for relatively fluid metals, and the casting mass must be between 30 grams and 10 kilograms. There will always be voids in the last batch of castings in normal die casting. Therefore, no heat treatment or welding can be performed because the gas in the gap will expand under the action of heat, causing internal micro-defects and peeling of the surface.

Hot Chamber Die Casting and Cold Chamber Die Casting

There are two different ways of making parts in die casting: hot chamber die casting and cold chamber die casting. In both manufacturing processes, the molds are sprayed with a release agent prior to the casting process to ensure that subsequently cast parts can be easily removed from the molds. However, the melt is not poured directly into the mold cavity but first poured into the casting cavity of the die casting machine. From there, the alloy is pressed into the mold by a piston (a so-called casting group) through one or more channels. The difference between the two processes is the structure of the casting chamber, as described below.

Hot Chamber Die Casting

In hot-chamber die-casting, its metal pool is a molten state of liquid, semi-liquid metal that fills the mold under pressure. The advantages of this system include high cycle speed (approximately 15 cycles per minute), ease of automation, and ease of melting the metal. Disadvantages include the inability to die-cast metals with higher melting points and the inability to die-cast aluminum, which would carry iron out of the molten pool. Thus, hot chamber die casting machines are generally used for alloys of zinc, tin, and lead. Moreover, hot chamber dies casting is difficult to use for die casting large castings, which are usually die casting of small castings.

Cold Chamber Die Casting

Cold chamber die casting can be used when die casting metals that cannot be used in the hot chamber die casting process, including aluminum, magnesium, copper, and zinc alloys with higher aluminum content. The metal needs to be melted first in a separate crucible in this process. A quantity of molten metal is then transferred to an unheated injection chamber or nozzle. These metals are injected into the mold by hydraulic or mechanical pressure.

The biggest disadvantage of this process is the long cycle time due to the need to transfer the molten metal into the cold chamber. Cold chamber die-casting machines are also divided into vertical and horizontal types. Vertical die-casting machines are usually small machines, while horizontal die-casting machines have various models.

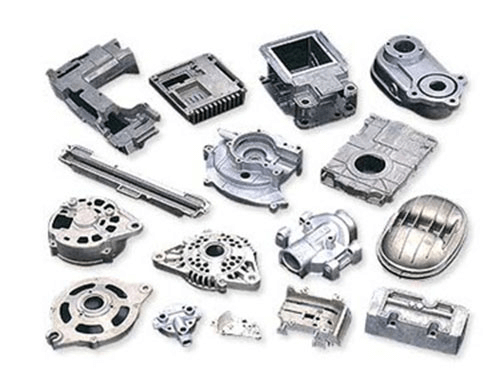

Application Areas of Die Casting

Die casting is mainly used for mass production, i.e., for casting many parts of the same type. High casting quality is achieved despite the high pressure used in the manufacturing process. The die casting process is particularly suitable for producing very thin (up to 1 mm) (lightweight) parts.

Most commonly, die-cast components such as wheels, cylinder blocks, cylinder heads, valve bodies, and manifolds are manufactured for the automotive industry. In addition, other industries use die castings:

- Aerospace

- Household appliances

- Furniture

- Electrical tools

- Electronic products

- Mechanical

- Lighting technology

In the future, foundries will be interested in other industries such as electric vehicles. This offers great potential for light metal castings.

Choose a Trusted Die Casting Company

Die casting has been widely used in manufacturing since the 19th century. As a top die casting service provider in China, JTR has been providing customers with complete die casting solutions for many years. High-quality die casting service is the key to our profitability. So if you need to implement your design, you can contact us. You just need to complete the design or creativity, and we will do the rest.