As a lightweight structural material, plastic has been increasingly used in the processing and manufacturing of parts. The unique properties of PVC make it a popular plastic material for CNC machining and manufacturing for a variety of applications and needs.

Why is PVC popular? Does it have any advantages in the field of parts processing? What products are made with it?

What is PVC machining?

PVC material is polyvinyl chloride, which is one of the largest plastic products in the world. PVC is cheap and widely used. Polyvinyl chloride resin is a white or light yellow powder, which cannot be used alone and must be modified.

PVC is a white powder with an amorphous structure, a small degree of branching, and poor stability to light and heat. Different additives can be added according to different uses, and PVC plastics can exhibit different physical and mechanical properties. Adding an appropriate amount of plasticizer to polyvinyl chloride resin can make a variety of hard, soft, and transparent products.

PVC machining refers to the use of PVC for injection molding and other processing methods to make PVC materials into products we need, such as plugs, semiconductor components, etc.

Advantages & Disadvantages of PVC Plastic

Advantages of PVC machining:

- Rigid PVC is one of the most widely used plastic materials.

- PVC material is an amorphous material. In practical use of PVC materials, stabilizers, lubricants, auxiliary processing agents, pigments, impact resistance agents, and other additives are often added.

- PVC material has non-flammability, high strength, weather resistance, and excellent geometric stability.

- PVC has strong resistance to oxidizing agents, reducing agents, and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid and is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

Disadvantages of PVC machining:

- The flow characteristics of PVC are quite poor, and its process range is very narrow. In particular, high molecular weight PVC materials are more difficult to process (such materials are usually added with lubricants to improve flow characteristics), so small molecular weight PVC materials are usually used.

- The shrinkage rate of PVC is quite low, generally 0, 2–0, 6%.

- PVC is easy to release toxic gas during the molding process.

What kind of parts can PVC be used for?

Profiles are the largest area of PVC consumption, accounting for about 25% of the total PVC consumption. PVC is mainly used to make doors and windows and energy-saving material. At present, its application volume is still increasing by a large margin across the country. The market share of plastic doors and windows is also the highest, such as 50% in Germany, 56% in France, and 45% in the United States.

But since PVC has excellent dielectric strength, it is a good insulating material. And it’s also resistant to weathering, chemicals, corrosion, impact, and abrasion, so it’s the material of choice for long-life and outdoor products.

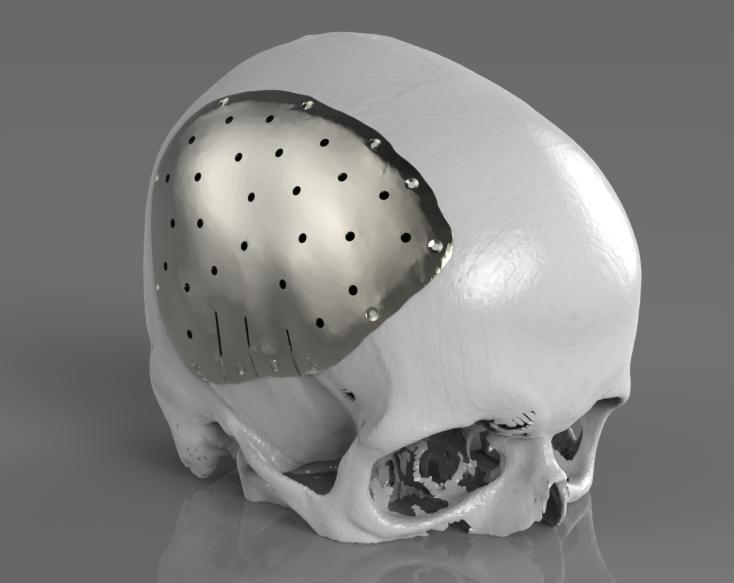

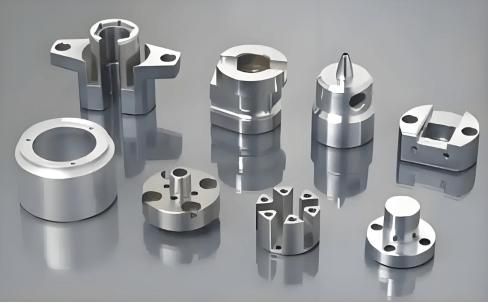

PVC can be reprocessed by CNC machining services into PVC rings, PVC bushings, wear parts, rollers, electronic components, semiconductor components, gaskets, insulators, pipe and valve components, fittings, joints, and custom designed PVC pieces, etc.

It is precisely because of the huge market demand that PVC processing has become a new field in which modern parts processing companies are competing.

How to CNC Machine PVC?

To improve the manufacturing quality of PVC machined parts, there are many important aspects to consider.

(1) Choose the right tool: Plastic is very unstable during processing, and only the right tool can ensure the safety and reliability of the manufacturing process.

(2) Processing conditions: Please note that its maximum working temperature is 100+F to 200+F.

(3) Setting considerations: including PVC processing speed, friction, bite angle, pressure, and the number of teeth. When processing PVC, it is best to work at lower speeds and with as little force as possible.

(4) Immediately remove debris from parts and use coolant appropriately.

(5) CNC milling: face milling using high tangent or high shear geometry tools

(6) CNC drilling: use slow to medium speed with only slight downward pressure. When drilling 1/4-inch or larger holes, choose a spade bit or a bit designed specifically for drilling plastics.

Typically, the processing of high-volume PVC parts requires professional guidance for efficient, high-quality completion. Just like our JTR, our CNC machining is supervised by engineers to ensure the qualified rate of products and the excellent performance of CNC machining parts.