In the intricate realm of manufacturing, precision holds the key to excellence, and nowhere is this more evident than in the realm of CNC small parts manufacturing. As technology advances, precision machining has become synonymous with the artistry of crafting intricate components with utmost accuracy. Among the various methodologies, Computer Numerical Control (CNC) has emerged as a game-changer, revolutionizing the way small parts are manufactured. This article delves into the fascinating world of precision machining, specifically exploring the nuances of CNC small parts manufacturing. From the underlying principles to the cutting-edge technologies involved, let’s unravel the precision-driven journey.

What is CNC Small Parts Manufacturing?

CNC Small Parts Manufacturing refers to the process of creating small and intricate components using Computer Numerical Control (CNC) machines. CNC machines are automated tools that follow pre-programmed instructions to control the movement of machinery and tools. In the context of small parts manufacturing, CNC technology allows for precise and detailed machining of components with minimal human intervention.

What Types of CNC Machines Used for Small Parts Manufacturing?

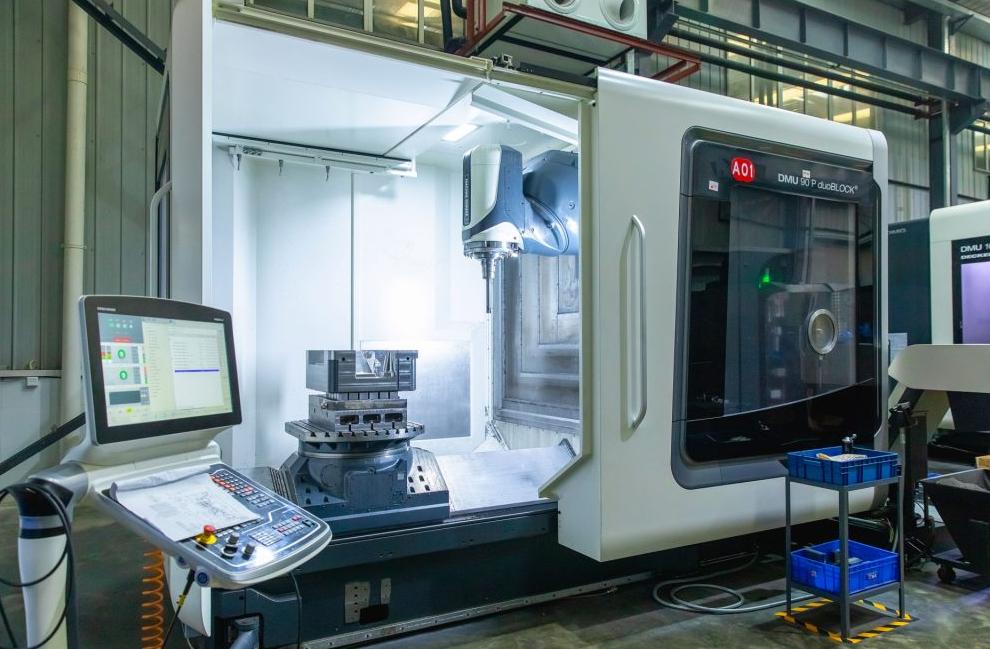

Several types of CNC (Computer Numerical Control) machines are commonly used in small parts manufacturing to achieve precision and efficiency. Each type of CNC machine is designed for specific machining operations. Here are some common types used in the production of small parts:

Vertical Machining Centers (VMCs): These machines have a vertically oriented spindle, and the workpiece is clamped in a vertical position. They are suitable for milling operations, including cutting, drilling, and tapping.

Horizontal Machining Centers (HMCs): In HMCs, the spindle is oriented horizontally, and the workpiece is placed on a horizontal table. These machines are useful for complex machining tasks and multiple-side machining.

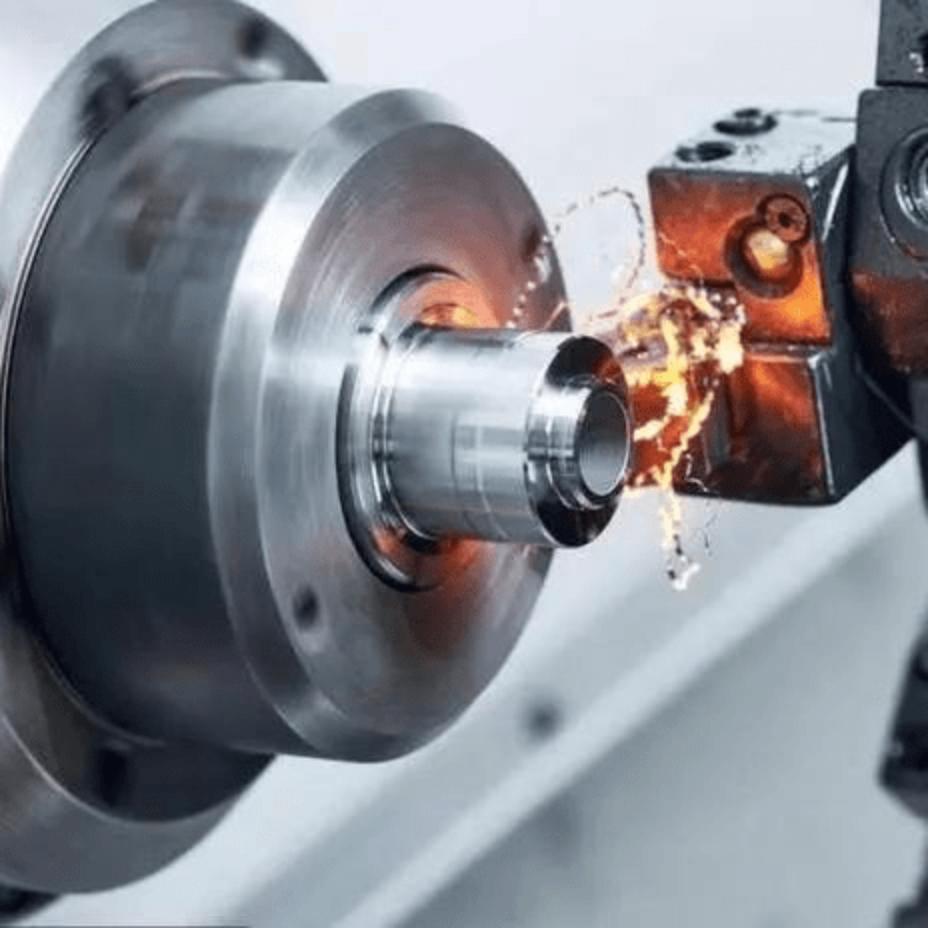

CNC Lathes: Lathes are used for turning operations, where the workpiece rotates while the cutting tool remains stationary. CNC lathes can produce cylindrical parts, including those with intricate details.

CNC Swiss Machines: Swiss-type CNC machines are specifically designed for small, intricate parts. They use a sliding headstock and guide bushing to support and guide the workpiece, enabling high-precision turning and milling operations simultaneously.

Wire EDM machines use a thin electrically charged wire to cut through the workpiece. This process is ideal for producing intricate and delicate parts with tight tolerances.

CNC Grinding Machines: CNC grinders are employed for precision grinding operations. They can produce small parts with high surface finishes and tight tolerances.

- CNC Laser Cutting Machines:

Laser cutting machines use a focused laser beam to cut through materials. They are suitable for producing small parts from sheets of various materials, such as metal, plastic, or wood.

CNC Waterjet Cutting Machines: Waterjet machines use a high-pressure stream of water mixed with abrasive materials to cut through materials. They are versatile and can handle a wide range of materials for small parts production.

These CNC machines offer versatility and precision, allowing manufacturers to meet the demands of producing small parts with intricate designs and tight tolerances across various industries. JTR Machinery has more than 70 precision CNC processing equipment of various types including lathes, milling machines, drilling machines, and grinders. The choice of machine depends on the specific requirements of the part and the material being used. Please feel free to contact JTR for more details.

What Materials Used in CNC Small Parts Manufacturing?

CNC Small Parts Manufacturing involves the machining of various materials to create precise and intricate components. The choice of material depends on the specific application and the desired properties of the finished part. Here are some common materials used in CNC small parts manufacturing:

- Metals:

- Aluminum: Lightweight and corrosion-resistant, aluminum is frequently used for small parts in industries such as aerospace and electronics.

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is often chosen for parts requiring durability and a polished finish.

- Brass: Brass is valued for its excellent machinability and aesthetic appeal, making it suitable for decorative or functional small parts.

- Acrylic: Transparent and lightweight, acrylic is commonly used for small parts in applications where optical clarity is essential, such as in electronic displays.

- Nylon: Nylon is a versatile and durable plastic used for small parts requiring high strength, flexibility, and resistance to wear.

- Delrin (Polyoxymethylene): Delrin is a thermoplastic known for its low friction and high stiffness, making it suitable for small parts in precision engineering.

- Composites:

- Carbon Fiber Reinforced Polymers (CFRP): Combining strength and lightweight properties, CFRP is used for small parts in aerospace, automotive, and sporting goods.

The selection of materials is influenced by factors such as the application’s functional requirements, environmental conditions, and cost considerations. CNC machining processes can accommodate a wide range of materials, allowing manufacturers to tailor their choices based on the specific needs of the small parts they are producing.

Why Choose CNC for Small Parts Manufacturing?

Choosing Computer Numerical Control (CNC) machining for small parts manufacturing offers several advantages:

- Precision and Accuracy: CNC machines can achieve high levels of precision and accuracy in small part manufacturing. The computer-controlled process ensures that each part is produced with consistency and minimal errors.

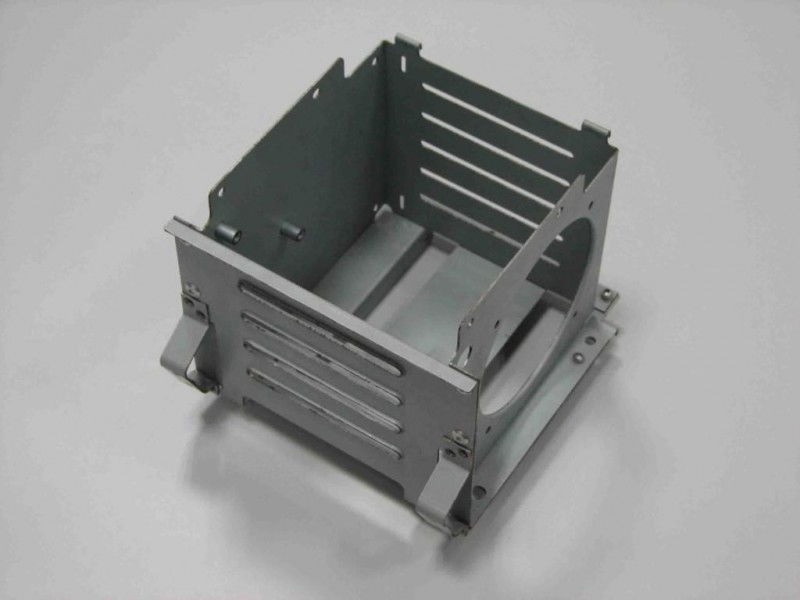

- Complex Geometries: CNC machining allows for the production of intricate and complex geometries that may be challenging or impossible with traditional machining methods. This is especially beneficial for small parts with intricate designs.

- Repeatability: CNC machining offers excellent repeatability, meaning that the same design can be replicated consistently over multiple production runs. This is crucial for maintaining quality and meeting specific tolerances in small part manufacturing.

- Versatility: CNC machines can work with various materials, including metals, plastics, and composites. This versatility makes CNC machining suitable for a wide range of small part applications across different industries.

- Efficiency and Speed: CNC machining is generally faster than traditional manual machining methods. The automation of the process, along with the ability to run machines continuously, contributes to higher efficiency and quicker production times for small parts.

- Cost-Effectiveness: While CNC machines may have higher initial costs, they can lead to cost savings in the long run due to reduced labor costs, decreased material waste, and improved efficiency in the production process.

- Customization: CNC machining allows for easy customization of small parts. Design changes can be quickly implemented in the computer program, making it feasible to adapt to specific requirements or design iterations.

- Scalability: CNC machining is scalable, meaning it can be employed for both small-scale and large-scale production of small parts. This flexibility is beneficial for businesses that may experience changes in production volume.

- Automation: CNC machining is a highly automated process, reducing the need for manual labor. This not only improves efficiency but also minimizes the likelihood of errors caused by human factors.

- Quality Control: CNC machines often come with advanced monitoring and quality control features. This ensures that each small part meets the specified quality standards, contributing to overall product reliability.

In summary, CNC machining is a preferred choice for small parts manufacturing due to its precision, versatility, efficiency, and the ability to handle complex designs.

Specific Applications of CNC Small Parts

CNC small parts find applications across various industries due to their precision, versatility, and ability to produce complex geometries. Here are specific applications of CNC small parts in different industries:

| Industry | Specific Applications of CNC Small Parts |

| Aerospace | Miniature Components (gears, connectors, sensor housings) |

| Instrumentation (brackets, mounts, instrument components) | |

| Medical | Implant Components (orthopedic implants, dental prosthetics) |

| Diagnostic Equipment (housings, connectors, specialized components) | |

| Electronics | PCB Components (connectors, housings, brackets for PCBs) |

| Microelectronics (components for microelectronic devices) | |

| Automotive | Sensor Housings, Connectors, and Brackets for Automotive Sensors |

| Fuel Injection Components | |

| Telecommunications | Connectors and Housings for Telecommunications Equipment |

| Antenna Components | |

| Defense and Military | Weapon Components |

| Optical and Laser Components | |

| Precision Engineering | Watch Components (gears, screws) |

| Optical Components (precision optics, lenses) | |

| Robotics and Automation | Robot Components (joints, gears, brackets) |

| Automation Equipment Components | |

| Consumer Electronics | Smartphone Components (camera housings, connectors, buttons) |

| Wearable Technology Components (fitness trackers, smartwatches) | |

| Tool and Die Manufacturing | Tool Components for Cutting Tools, Dies, and Molds |

Conclusion:

Precision machining through CNC technology has not only reshaped the landscape of small parts manufacturing but has also set new benchmarks for quality, efficiency, and innovation. As we conclude our exploration into this captivating world, it becomes evident that CNC small parts manufacturing is at the forefront of technological advancements, continually pushing boundaries and redefining possibilities. The intricate dance between man and machine, guided by precision and fueled by innovation, propels this industry forward. As we witness the evolution of CNC small parts manufacturing, it becomes clear that the precision-driven future holds endless opportunities for those at the intersection of craftsmanship and cutting-edge technology. If you are choosing a CNC small part manufacturer, believe JTR Machinery will not let you down.