PolyJet 3D Printing Service

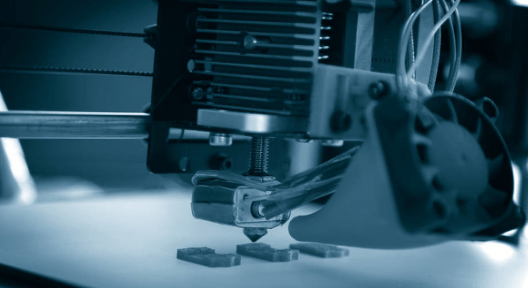

JTR Machine offers a PolyJet 3D printing service for both rapid prototyping and low-volume production. Polyjet Printing is a printing technique that uses an array of nozzles to spray liquid photosensitive resin layer by layer according to the model slice data, and then cure the resin with a UV lamp. Because of the diversity of printing materials and high processing accuracy, Polyjet Printing stands out from the many 3D Printing technologies. The diversity of materials and the guaranteed quality make us a trusted provider of Jolyjet 3D Printing services. Get your prototypes and end-use parts at a lower cost, reduced time, and higher quality.

Using the latest PolyJet 3D printing technology, we can provide you with rigid and flexible materials in the same construction. We can provide a variety of different materials in one print to complete the printing process. This means that the production of overmolding and flexible prototypes are easier, faster, and more cost-effective than ever before.

Our PolyJet 3D Printing Capabilities

| Requirement | Maximum build size | Min Feature Size | Dimensional accuracy | Description | Build modes digital material | Minimum layer thickness | Lead time |

| Specification | 490 x 390 x 200 mm | 0.3 mm | ±0.1-0.2mm | Widely known for a great material selection, accuracy, and possibility to print large parts. | 30-micron (.001 in.) resolution | horizontal build layers as fine as 16 microns (.0006 in.) | 1 day |

PolyJet 3D Printing Materials

Agilus30

The agilus30 series is an upgraded version of Tangoplus rubber material, with better mechanical properties, composed of Agilus30 and Agilus30 Black. Agilus 30 provides users with a soft rubber-like material, which is very suitable for modeling precision parts. These materials can help users handle and test flexible parts and prototypes more flexibly while providing excellent accuracy, fine details, and enhanced product authenticity.

Digital ABS Plus

Simulated ABS Plastic for High-Temp Resistance and Toughness.

Digital ABS Plus creates realistic, precise parts and tools that are tough and heat resistant. Designed to simulate durable production plastics, Digital ABS Plus delivers high impact strength with high-temperature resistance and superior finish.

Polypropylene-like

Stratasys offers two PolyJet photopolymers that simulate the appearance and functionality of polypropylene.

VeroUltra Opaque

Superior opacity, color uniformity, contrast, and sharpness.

The new opaque colors enable the perfect simulation of high-quality injection molded parts. These new colors meet the 2D graphics standards while providing strong color contrast and color separation. Super realistic labels, graphics, or text can be added to the model to simulate silkscreen printing or printed stickers.

Tango

3D print soft-touch, flexible prototypes.

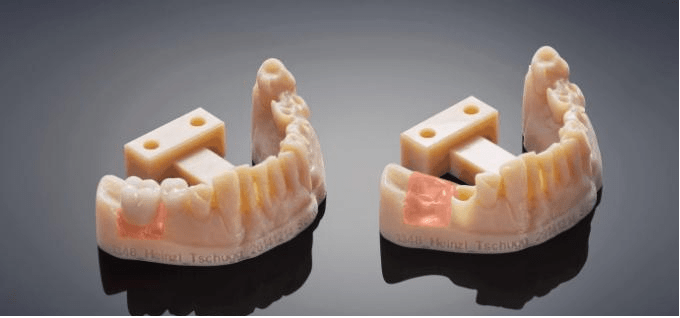

Bio-compatible Material

Using 3D Printing With Bio-compatible Material, you can quickly make prototypes of medical and dental products, including dental delivery trays, surgical orthopedic guides, and hearing aids. Medical rapid prototyping materials have excellent visibility and excellent dimensional stability.

Overview of PolyJet 3D Printing

What is PolyJet 3D Printing?

PolyJet is a 3D printing technology that can build parts by jetting thousands of photopolymer droplets onto a build platform and using UV curing. It is one of the fastest and most accurate 3D printing technologies currently available.

In the PolyJet 3D printer product series, 29 basic resins can enrich technical functions. But what makes PolyJet technology truly stand out is that it can not only combine multiple materials in a single part (multi-material 3D printing) but also select and mix basic resins from 29 basic resins to create mixed material properties and color. This is what it means to use digital materials for 3D printing, and the technology provides more than 500,000 different material options.

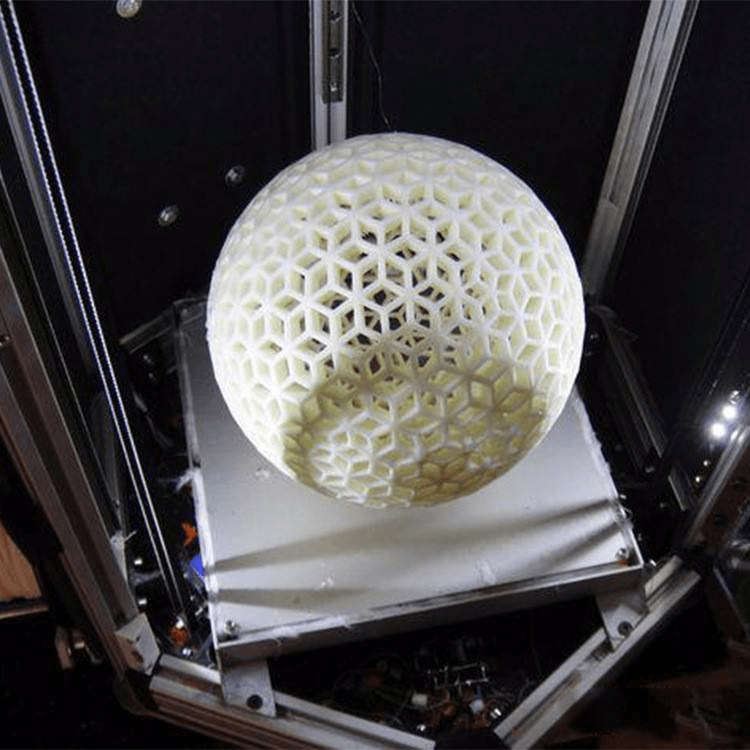

PolyJet 3D printed parts have high precision, high resolution, and smooth surfaces. After printing, remove the support material and the part can be used immediately without post-curing. In addition, PolyJet photosensitive resin complies with REACH regulations and is safe and harmless to the environment.

Advantages of PolyJet 3D printing

Can print fine prototypes with a smooth surface to maximize the beauty of the final product.

Can manufacture precise molds, drilling dies, fixtures, and other manufacturing tools.

It can handle complex shapes and details, showing exquisite characteristics.

Multiple colors and materials can be applied to a single model at the same time to improve efficiency.

Multi-Material and Full-Color Printing for PolyJet 3D Printing

The main advantage of Polyjet lies in its ability to produce accurate multi-material and multi-color prints that represent the final product.

Multi-material and multi-color printing in Polyjet can be divided into three different levels:

1. When constructing the area, different parts can be designed to be printed with different materials or colors at the same time, thus speeding up the manufacturing process.

2. At the part level, you can specify different parts of the part to be printed with different materials or colors (for example, use a hard box with flexible buttons to make a prototype).

3. In the diversity of materials, two or more printing resins can be mixed in different proportions and then distributed to make “digital materials” with specific physical properties (such as hardness and rigidity requirements).

To assign different materials or colors to specific areas of the part, the model must be exported as a separate STL file. When mixing colors or material attributes to make digital materials, you must export the design as an OBJ or VRML file, because these formats allow special attributes (such as texture or color) to be specified on a per-face or per-vertex basis.