When people talk about the metal casting process, the words most often heard are “sand casting” and “permanent mold casting“. They are also important casting methods, but their application fields are very different. Are you interested in taking five minutes to learn about it? This article will use as simple terms as possible, in the shortest time, to introduce you to their differences.

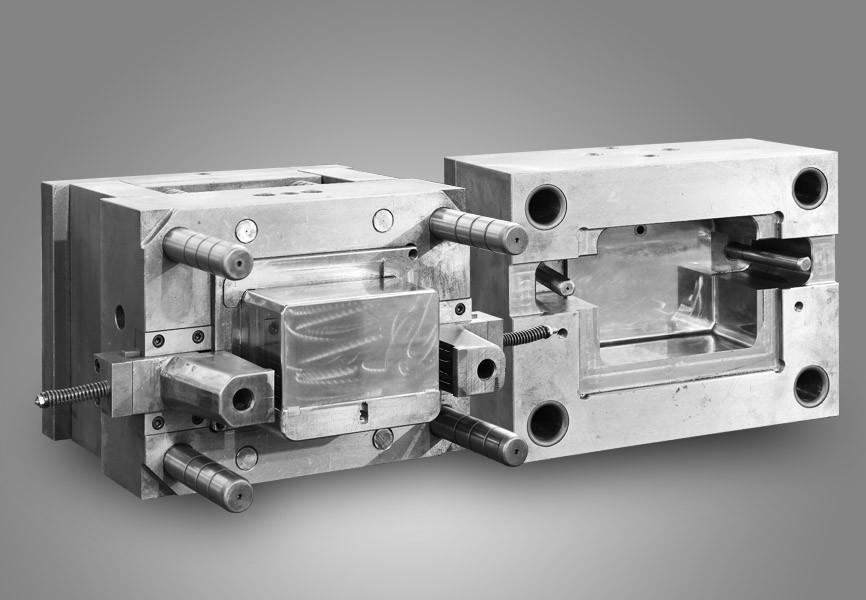

What is permanent mold casting?

Metal mold casting, also known as hard mold casting, is a casting method in which liquid metal is poured into a metal mold to obtain castings. Molds are made of metal and can be used multiple times (hundreds to thousands). The castings that can be produced by metal mold casting are limited in weight and shape. For example, ferrous metals can only be castings with simple shapes; castings cannot be too heavy. And there is also a limit to the wall thickness of the casting, and the smaller casting cannot be cast with a thin wall thickness.

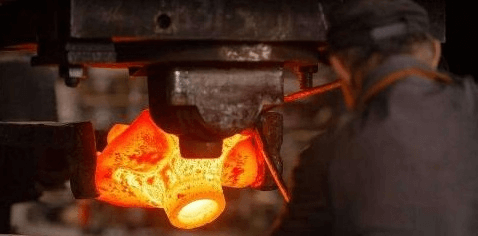

What is sand casting?

Sand casting refers to a casting method in which castings are produced in a sand mold. Steel, iron, and most non-ferrous alloy castings can be obtained by sand casting. Because the molding materials used in sand casting are cheap and easy to get, the casting mold is simple to manufacture, and can be adapted to the single-piece production, batch production, and mass production of castings, and has been the basic process in casting output for a long time.

What is the difference between permanent mold casting and sand casting? Which is better?

1. Advantages and disadvantages of sand casting and metal casting

The advantages of permanent mold casting:

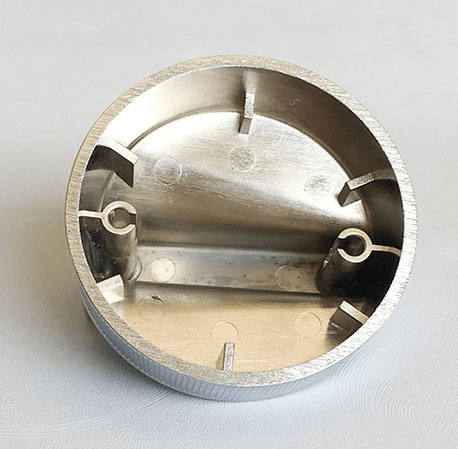

(1) Castings produced by metal molds have higher mechanical properties than sand castings. For the same alloy, its tensile strength can be increased by 25% on average, yield strength can be increased by about 20% on average, and its corrosion resistance and hardness are also significantly improved;

(2) The precision and surface finish of castings are higher than those of sand castings, and the quality and size are stable;

(3) The process yield of castings is high, and the consumption of the liquid metal is reduced, which can generally save 15-30%;

(4) No sand is used or less sand is used, which can generally save 80-100% of molding materials; in addition, the production efficiency of metal mold casting is high; the causes of casting defects are reduced; the process is simple, and it is easy to realize mechanization and automation.

2. Disadvantages of permanent mold casting:

(1) The manufacturing cost of metal molds is high;

(2) The metal mold is airtight and has no concession, which is easy to cause defects such as insufficient washing, cracking, or daylight of the casting;

(3) During metal mold casting, the working temperature of the mold, the pouring temperature and pouring speed of the alloy, the time the casting stays in the mold, and the paint used are very sensitive to the quality of the casting, and need to be strictly controlled.

Therefore, when deciding to use metal mold casting, the following factors must be comprehensively considered: the shape and weight of the casting must be appropriate; there must be enough batches; the deadline for completing the production task permits.

The best solutions for casting problems!

If you need custom metal castings or parts, but don’t know where to start, JTR will be your best helper. At JTR, we receive more than 50 metal casting requests every month.

We have always tried to bring the greatest benefit to our customers with the most suitable manufacturing method. Therefore, if you need us to help you with your manufacturing process, please contact us and you will get a quote in the shortest possible time and see your product within the shortest delivery date.