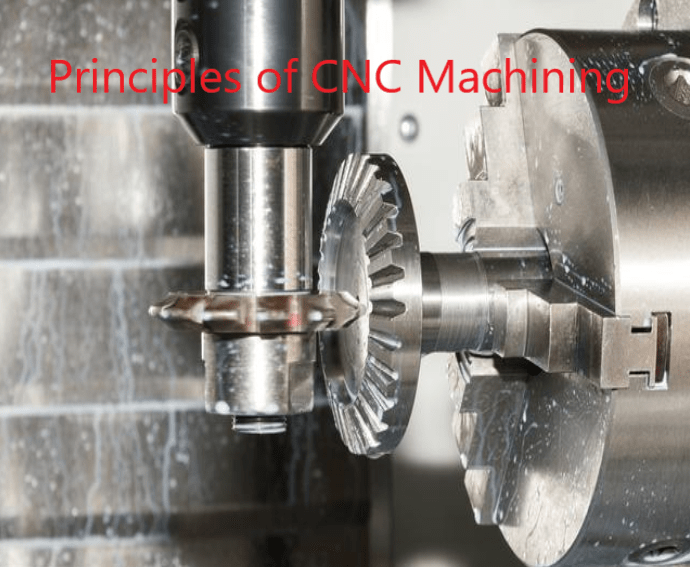

CNC machining has been in the manufacturing industry for many years, and it has always been the mainstream manufacturing method. But its supremacy has been challenged in recent years, as more novel methods of machining parts have emerged, such as additive manufacturing (AM). Some people began to question whether CNC machining can continue its glory? Will the advantages of the new technology surpass CNC machining?

Through the processing of a small screw, this article will answer the question of whether CNC machining has the possibility of being replaced.

The method of CNC machining a screw

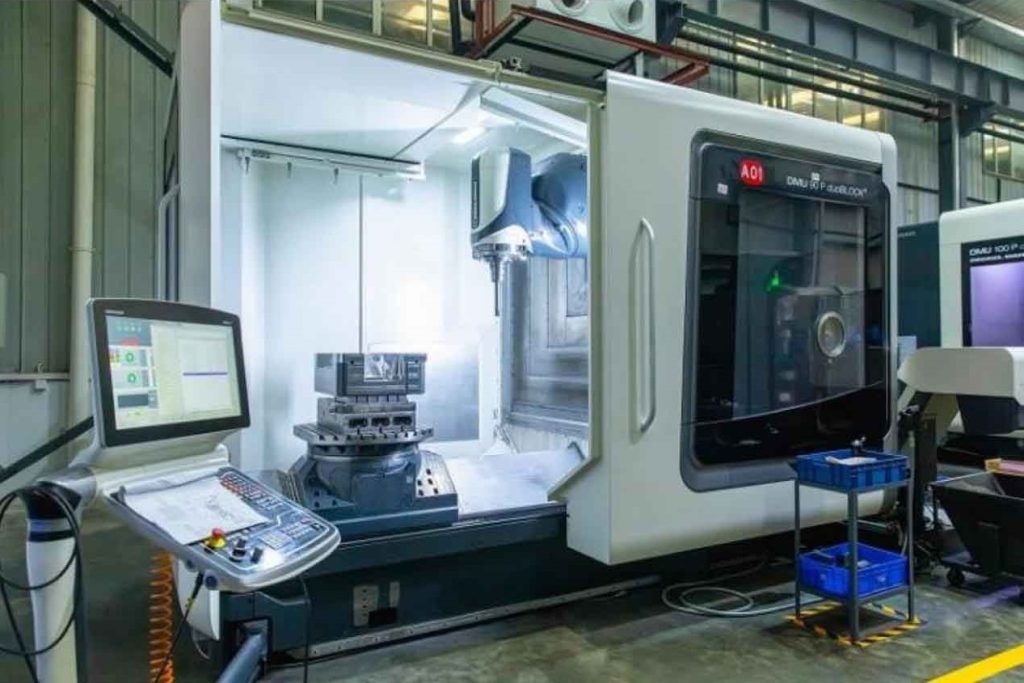

So far, CNC machining is still the mainstream screw processing method, especially now that the CNC machining factory has been upgraded to a CNC machining center.

Everyone has a deep understanding of the benefits of using CNC machining centers to process workpieces. There is still a mysterious veil on the operation and programming of CNC machining centers. There are three ways to use CNC machining: thread milling method, tap processing, and pick processing method:

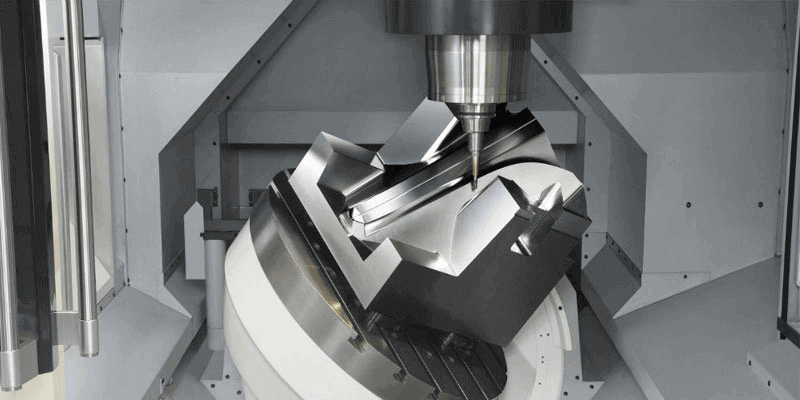

Thread milling method for machining screws

Thread milling is the use of thread milling tools for the processing of large-hole threads, as well as the processing of threaded holes with difficult-to-machine materials. It has the following characteristics:

1. The tool is generally made of cemented carbide material, with fast speed, high thread milling precision and high processing efficiency;

2. The same pitch, whether it is a left-handed thread or a right-handed thread, can use a tool to reduce the cost of the tool;

3. The thread milling method is especially suitable for the thread processing of difficult-to-machine materials such as stainless steel and copper. It is easy to remove chips and cool, and can ensure the quality and safety of processing;

4. There is no tool front guide, which is more convenient to process blind holes with short threaded bottom holes or holes without undercuts.

Thread milling tools are divided into two types: machine-clamped carbide insert milling cutters and integral cemented carbide milling cutters. Machine-clamped tools can not only process holes whose thread depth is less than the length of the blade, but also can process holes whose thread depth is greater than the length of the blade. Holes; and solid carbide milling cutters are used to machine holes whose thread depth is less than the length of the tool.

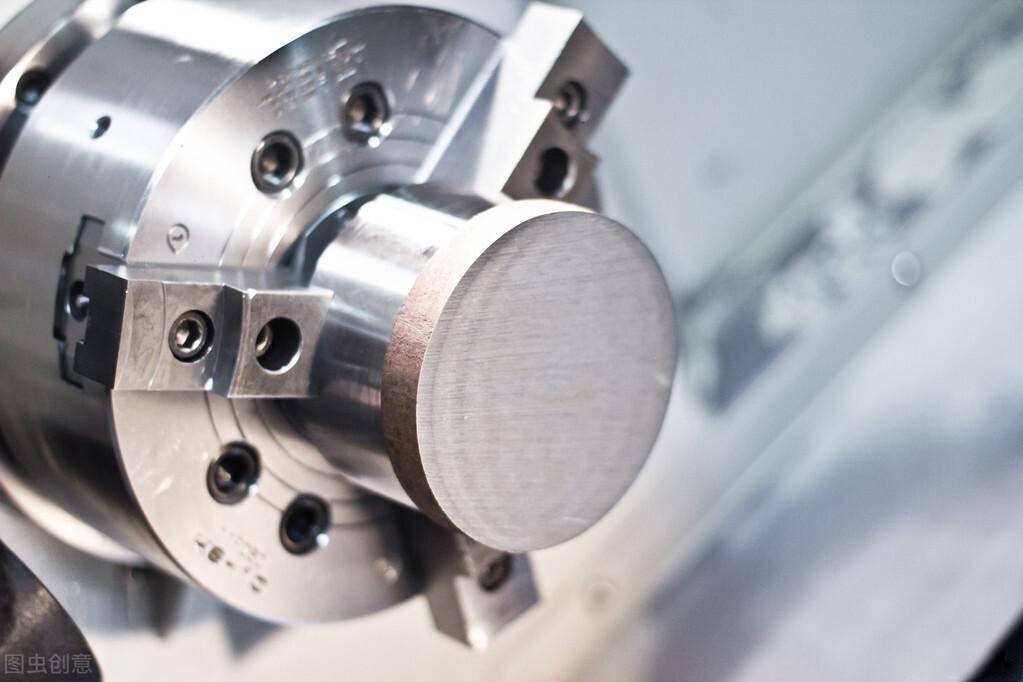

CNC machining center tap processing method

It is suitable for threaded holes with small diameters or low hole position accuracy requirements. Generally, the diameter of the threaded bottom hole drill is close to the upper limit of the diameter tolerance of the threaded bottom hole, which can reduce the machining allowance of the tap and reduce the load of the tap. Improve the service life of the tap.

We need to choose the appropriate tap according to the material to be processed. The tap is relative to the milling cutter and the boring cutter.

It is very sensitive to the material to be processed. Taps are divided into through-hole taps and blind-hole taps. The front-end guide of through-hole taps is long for front chip removal. When processing blind holes, the processing depth of the thread cannot be guaranteed, and the front-end guide of blind holes is short for rear chip removal, so pay attention to the difference between the two. When using a flexible tapping chuck, pay attention to the diameter of the tap shank and the width of the square to be the same as that of the tapping chuck. The diameter of the tap shank for rigid tapping should be the same as that of the spring. The jacket diameter is the same.

The programming of the tap machining method is relatively simple, all of which are fixed modes, and it is enough to add parameter values. It should be noted that different numerical control systems and subprogram formats are also different, so the representative meaning of the parameter values is different.

Will 3D printing replace CNC machining?

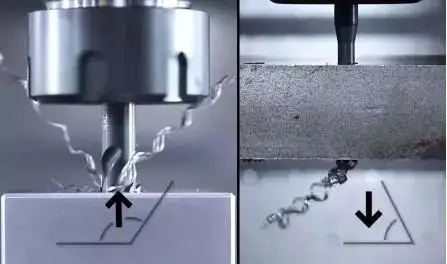

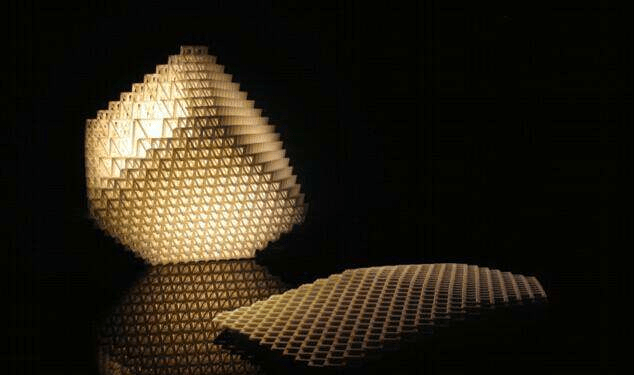

3D printing is a kind of additive manufacturing, which realizes the manufacture of objects through the superposition of materials. While CNC machine tools are subtractive manufacturing, which makes objects through the reduction of materials. CNC machine tool is a very mature manufacturing equipment, which has been widely used in traditional manufacturing. While 3 printing is a new manufacturing theory, and the technology is still under research and development.

Of course, in the pursuit of sustainable development in modern times, 3D printing has great advantages in saving resources and utilization of resources, and at the same time, it is more efficient in manufacturing complex objects.

It is very convenient if we want to use 3D printing to make a screw (although it will take a little longer to make). But what if we wanted to use 3D printing to make a lot of screws in a short amount of time? This is not realistic. The way 3D printing works and its technical characteristics have shown that it is not suitable for high-volume product manufacturing.

Compared with 3D printing, CNC machining has good stability because it is a CNC machine that runs continuously according to the set processing program. And because the cost of CNC machining is lower than that of 3D printing, CNC machining is more advantageous for machining screws.

What is the difference between 3D printing and CNC machining?

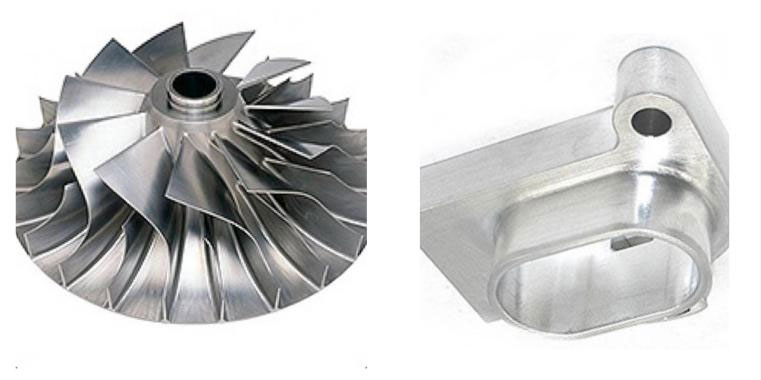

- Scope of production. The machinable range of 3D printing technology is larger than that of CNC manufacturing. 3D printing has a high degree of freedom and can make difficult or impossible geometries that cannot be done by CNC.

- Development level. The CNC machining industry has a mature set of standards, including spindles, tool interfaces and control systems, but there is no such established standard in the 3D printing field.

- Product volume. 3D printing is difficult to make very large pieces, but CNC can handle it.

- Process type. 3D printing is an additive manufacturing method that builds up models, while CNC is a subtractive manufacturing process that continuously cuts and removes the entire raw material.

We can’t say that direct additive manufacturing is not good or CNC machining is not good, but for manufacturing companies, the advantages brought by CNC machining are higher than additive manufacturing (except for companies that sell customized products).

Therefore, I think CNC machining will still be in the manufacturing industry, and the processing industry will maintain its unshakable position.

JTR is a professional manufacturer that provides CNC machining services and 3D printing services. If you are not sure whether your company’s products are suitable for CNC machining or 3D printing, please contact us. Or we can directly complete the CNC machining of the product for you. The CNC machining capability of JTR is worthy of your trust.