It is critical to thoroughly compare 3-axis, 4-axis, and 5-axis CNC machining technologies, as each has distinct application scenarios and advantages. 3-axis CNC machining is appropriate for parts with simple geometric shapes, whereas 4-axis and 5-axis CNC machining can handle more complex shapes and surfaces, particularly 5-axis machining, which can control all five degrees of freedom simultaneously, allowing for the machining of complex curves and surfaces. By comparing CNC machining technologies with varying axe counts, resources can be more effectively allocated and the best machining method can be chosen, lowering costs and increasing production efficiency.

3-Axis CNC Machining

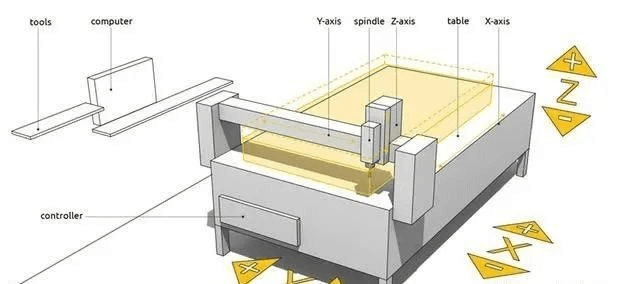

Three-axis CNC (computer numerical control) machine tools are computer-controlled machines that can move and process materials in three directions (typically X, Y, and Z). The axes represent horizontal (X), vertical (Y), and depth (Z) movements. The working principle is based on a predetermined machining program, and the material is cut, drilled, milled, and other machining operations are accomplished by precisely controlling the tool’s movement along these axes.

Advantages of 3-Axis Machining

- Cost-effectiveness: Three-axis CNC machine tools have lower initial and ongoing maintenance costs than more advanced multi-axis machine tools, making them ideal for small and medium-sized businesses or projects with limited budgets.

- Easy to operate: The operating interface is relatively intuitive, and the programming and operation technology thresholds are low, making it simple to learn and master.

- Suitable for plane or simple surface processing: Three-axis machine tools are effective for processing two-dimensional planes and simple three-dimensional surfaces.

Limitations of 3-Axis Machining

- Difficult to process complex surfaces: Because they only have three motion axes, three-axis CNC machine tools are limited in their ability to process complex three-dimensional surfaces and may require multiple clamping and adjustments, reducing processing efficiency and accuracy.

- Difficulty in simultaneous processing of multiple surfaces: 3-axis machine tools cannot complete tasks with multiple surfaces or angles in a single clamping, leading to increased processing steps and time.

4-Axis CNC Machining

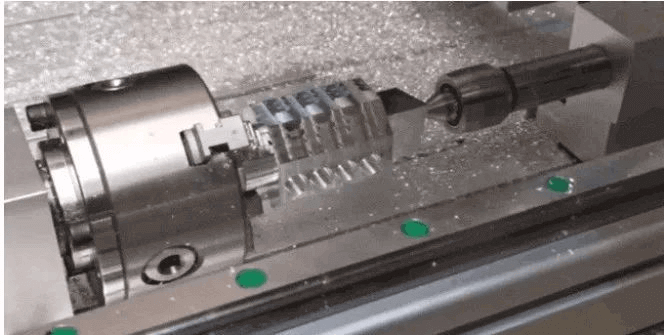

Four-axis CNC machines incorporate a rotary axis, known as the A or B axis, into the traditional three axes (X, Y, and Z), allowing the workpiece to perform rotational motion in addition to the three linear motions. This design greatly expands the machine’s machining capabilities, allowing for the machining of more complex three-dimensional shapes, particularly those that require rotation around an axis.

How Does the Addition of the 4-Axis Expand Machining Capabilities?

- Continuous cutting: Multiple surfaces can be machined in a single clamping, reducing the need to reposition and fix the workpiece while increasing machining efficiency.

- Complex surface machining: It can machine complex surfaces like spiral grooves and blades, which are difficult to achieve with three-axis machines or require multiple clampings.

- Improved accuracy: Reducing the need for multiple clamps improves machining accuracy by reducing errors from repeated positioning.

Application Scenarios of 4-Axis Machining

- Gears and gearboxes: The tooth surface and bottom of the gear can be machined all at once.

- Impellers and blades: These parts frequently require complex rotating surfaces, which four-axis machines can efficiently process.

- Cams and valves: These parts frequently have complex contours, which four-axis machining can accurately replicate.

Comparison of Machining Efficiency and Accuracy Between 3-Axis and 4-Axis

| 3-axis | 4-axis | |

| Machining Efficiency | Multiple clamping and workpiece position adjustment are usually required to process different sides, which will increase machining time and reduce efficiency. | Multiple surfaces can be machined in one clamping, significantly reducing non-machining time and improving production efficiency. |

| Machining Accuracy | Since multiple clampings are required, each clamping may introduce positioning errors, which will affect the accuracy of the final product. | By reducing the number of clampings, four-axis machining helps maintain higher machining consistency and accuracy. |

When it comes to machining parts with complex surfaces and symmetrical structures, four-axis CNC machine tools outperform three-axis machine tools in terms of both efficiency and accuracy. However, the investment and maintenance costs of four-axis machine tools are typically higher, so whether to use four-axis machining must also be determined based on specific application requirements and economic considerations.

5-Axis CNC Machining

A five-axis CNC machine is a sophisticated CNC machine tool that can move and rotate a workpiece or cutting tool in five distinct directions. These five axes typically include three linear axes (X, Y, and Z) and two rotational axes (A, B, or C). The addition of the rotary axis allows the machine tool to rotate around the vertical (X-axis) and horizontal (Y-axis), resulting in multi-angle processing of the workpiece.

Technical Advantages of 5-Axis Machining

Precise machining of complex geometries: Five-axis machining can machine multiple faces in a single setup, which is essential for producing complex geometries like turbine blades, propellers, and molds.

- Reduced fixture usage: Because five-axis machines can machine workpieces in multiple directions, there is less need to reposition and change fixtures, saving both time and money.

- Improve production efficiency: Five-axis machine tools improve production efficiency by reducing tool changes and simplifying machining processes.

- Improved accuracy and surface quality: Five-axis machining can keep the cutting tool in the optimal angle of contact with the workpiece at all times, increasing machining accuracy and surface finish.

Investment Cost and Operating Difficulty of 5-Axis Machine Tools

The investment cost of five-axis CNC machine tools is relatively high, owing to their complex mechanical structure, advanced control system, and precision components. Furthermore, maintaining and repairing such machine tools necessitates specialized skills and incurs higher costs.

Operating a five-axis machine tool is also more difficult than using a three-axis machine tool because the operator must have a thorough understanding of complex programming and machine tool kinematics. To make the most of a five-axis machine tool, specially trained technicians are frequently required. However, with the development of computer-aided manufacturing (CAM) software, programming has become more automated and user-friendly, thereby reducing operational complexity.

In general, while five-axis CNC machine tools are relatively expensive and difficult to operate, the technical benefits they provide, such as improved ability to process complex parts and increased production efficiency, make them essential equipment for many high-end manufacturing industries. For manufacturers looking for high precision, efficiency, and flexibility, investing in a five-axis machine tool is a long-term strategic decision.

Performance Comparison and Selection Guide

| Features/Indicators | 3-axis CNC machine | 4-axis CNC machine | 5-axis CNC machine |

| Number of axes | 3 | 4 | 5 |

| Workspace | Small | Medium | Large |

| Complexity | Simple | Medium | Advanced |

| Processing accuracy | Average | Good | High |

| Processing speed | Fast | Medium | Slow |

| Flexibility | Limited | Good | Excellent |

| Applicable materials | Various materials | Various materials | Various materials |

| Applicable scenarios | Basic contour processing | Rotating body processing | Complex surface processing |

| Cost | Low | Medium | High |

| Maintenance difficulty | Simple | Medium | Difficult |

Basic contour processing is best performed with a 3-axis CNC machine tool, which is inexpensive and simple to operate. Rotational body processing is best done with a 4-axis CNC machine tool, which is ideal for parts that require rotational processing, such as gears and cams. Complex surface processing is best done with a 5-axis CNC machine tool, which is ideal for processing complex parts in aerospace, automobile manufacturing, and other industries. Despite its higher cost, it can provide greater precision and efficiency. For more specific suggestions, please consult China CNC machining expert JTR.