With the development of digitization in the manufacturing industry, CNC machines approached more and more industries. In the 1940s, an initial NC machine was built, and in the following 50s, it kept improving, until in the 1970s CNC was made. Nowadays, CNC machining services have advanced sharply that almost all the global factories are in an outsmarted traditional CNC machines’ service.

The rise of CNC machine markets in the US – a big consumer of the CNC machining service – alone can be seen by the below graph.

CNC machining service

The changing pattern of CNC machining and manufacturing

As mentioned earlier, CNC machine tools have had a significant impact on the manufacturing field. Let’s take a closer look.

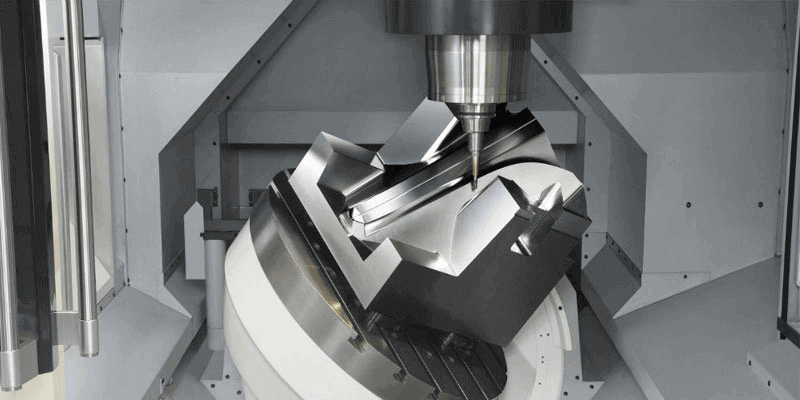

Embrace automation: CNC machining does not necessarily introduce the creation of any new objects, but changes the way of producing old objects. It realized the digitization of processes and the automation of multiple tasks, thus ushering in a new business model. For example, using CNC machine tools, plastic and metal parts can be produced easily and quickly through automatic programming for machining. The programming that is completed and run before the actual processing will not leave any room for error, and it can be repeated many times.

Meeting the needs of the Fourth Industrial Revolution: As the Fourth Industrial Revolution brings a surge in modern technology, manufacturing companies need to provide high-performance production methods and interconnected machining workshops. Without computer control, this is almost impossible. In addition, it is easy to use CNC for rapid prototyping directly from 3D CAD geometry.

Possibility of continuous seamless operation: Contrary to manual operators, CNC machine tools can run for a long time by eliminating the operator’s rest time. Once the program is set up and entered into the controller, an operation can continue except for machine maintenance and downtime.

The positive impact of CNC machining services on the manufacturing industry

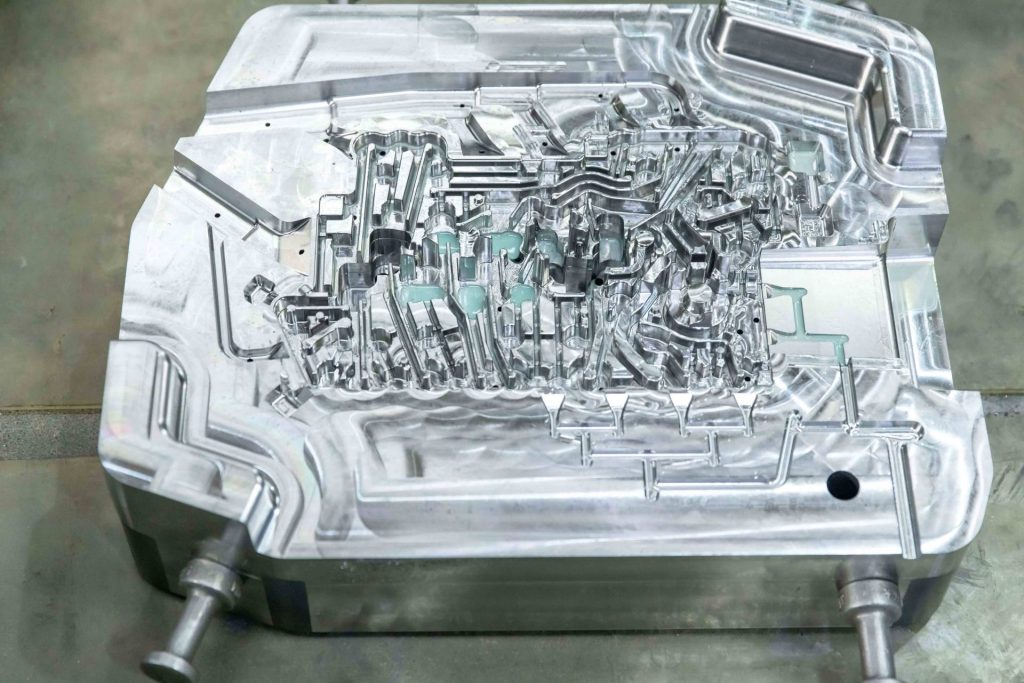

High-quality prototype machining is most needed in any vertical manufacturing field. CNC machining can provide this in a relatively low or even almost trouble-free manner. In addition, the cost of CNC machining services complements the quality of the final deliverables produced.

Advantages of CNC machine tools:

Improve productivity

Reduce waste

Higher product quality and consistency

Mass production initialization

Make more complex parts

The improved overall efficiency of the machining workshop

These effects have fundamentally increased the efficiency of the mechanical workshop to a height that design engineers had never imagined. CNC machining provides smaller manufacturing companies with options that are banned due to cost factors. All in all, for projects completed by keeping pace with the design, this blow includes convenience, precision, and accuracy.

For JTR, our CNC machine operators use our long-term expertise in the industry to work closely together to carefully develop code based on your design intent.

Brace Up To Embrace The New Bars Of Quality

It’d not be an exaggeration to say that with CNC machines, one can easily see overall betterment in the quality of their deliverables. In fact, not only that, computerized control machining may seem costly initially but in the long run, they invite huge economical savings. The reduced scrap and large volume handled at a time, give you an edge over the conventional machining operations.

Additionally, with an expert partner and a veteran in CNC machining services like JTR, get ready to raise the bars of your manufacturing efficiencies. Discuss your project today and we guarantee you the best quote.