In today’s increasingly digital world, engineers and designers rely on data that can be displayed on a screen to successfully produce models. But in product development, the importance of physically interacting with designs in the form of prototypes cannot be overstated.

Before the digital age, prototyping was a hands-on skill. The experienced staff creates 3D models of designs using a variety of handcrafting techniques. More recently, digitized design data has simplified the task of visualizing parts in 3D and improved the way designs transition from the screen to the physical world.

While the needs that prototypes address have not changed, namely fit testing and aesthetic decisions, functional and ergonomic testing, and low-speed initial production, the prototyping technology itself is constantly evolving. Read on for tips on using modern prototyping tools today and in the future.

Model making collaborates across distances and disciplines

For decades, design meetings have taken the form of a group of engineers sitting around a conference table and reviewing a physical prototype together.

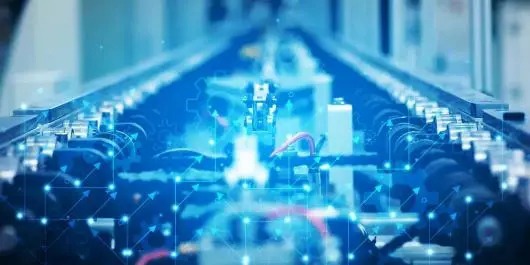

In today’s world, design teams are scattered across the globe, involving engineers responsible for mechanical, electrical, and code design, as well as marketing experts and suppliers. Modern CAD platforms allow engineers to simultaneously update designs and view changes made by team members in real-time from anywhere.

Optimize your parts with software

The product design process used to be based on iterative and incremental improvements. The topology generation module included in some CAD platforms speeds up changes. This technique, also known as generative design, feeds key performance and manufacturing requirements into software, which then returns a series of optimized designs capable of achieving specified performance while minimizing material usage.

In the future, organic topologies can help designers think differently about how parts look and function, and they can also reduce material waste to improve sustainability and cut costs.

Model prototype data can be analyzed in real-time

Engineers used to step through prototypes to make sure they performed as expected. In many cases, modern CAD tools can do the same job virtually.

Built-in analysis tools allow engineers to view responses to factors such as stress, fatigue, heating or cooling, fluid flow, and more before physical parts are created. To improve performance, they can iterate on the design and re-analyze on the fly.

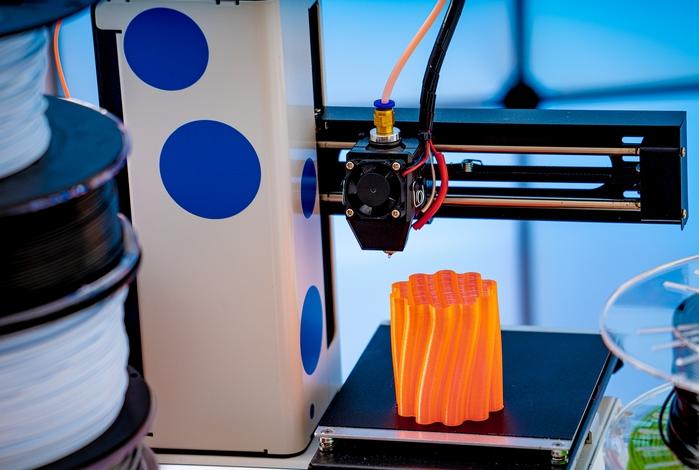

Send data to the 3D printer

Additive manufacturing, or 3D printing, is one of many ways to create physical prototypes. In some applications, engineers appreciate this approach because it can generate parts that cannot be made with other manufacturing techniques and do not require additional tools. To further simplify its application, some CAD platforms have file formats that are compatible with the generation of The software for 3D printing paths that work seamlessly together.

Generate a CNC program in one second

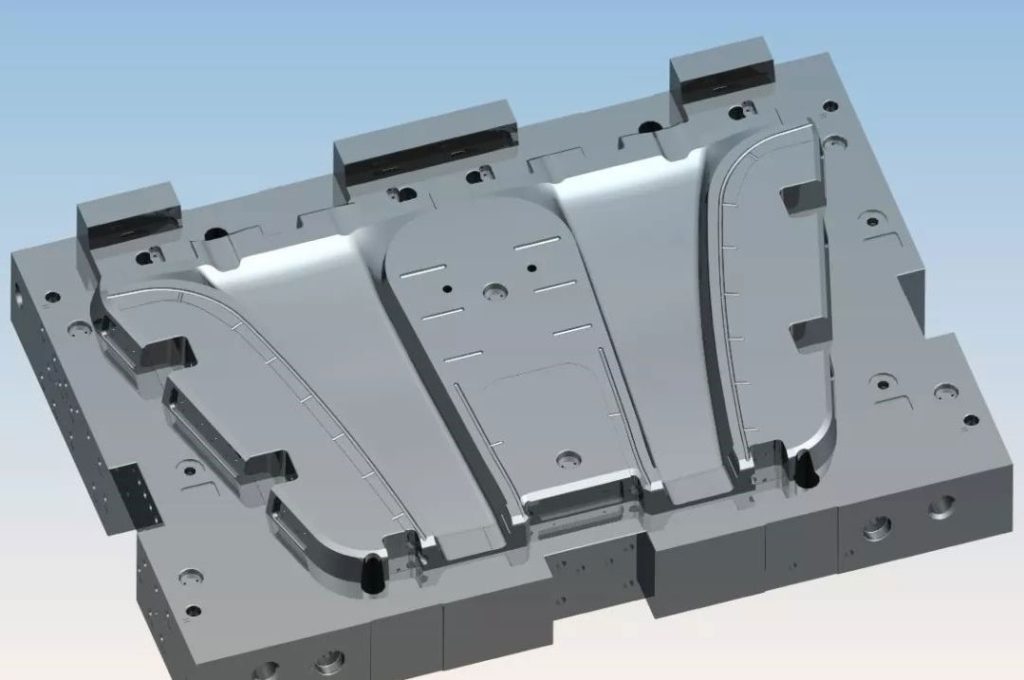

CNC machining is a subtractive manufacturing method for metals and engineering plastics, often used to generate physical prototypes. The code that controls the machining process used to be created manually or with stand-alone CAM software, but today’s CAD packages have integrated modules that create CNC manufacturing profiles. In some cases, these modules allow you to visually see the effect of material removal before machining begins.

Parts can be checked for manufacturing challenges

Design for Manufacture (DFM) used to be a technique that required manufacturing engineers to learn and accumulate over time. Physical prototypes are not always successful in detecting potential manufacturing hurdles because they are often manufactured using different techniques than those used in full-rate production.

Modern CAD software packages have DFM modules that flag manufacturability issues before products are put on the production line.

Customers can get quotes in real-time

While physical prototypes can give you a lot of tangible and intangible part-related experiences, they cannot predict how much outsourced production will cost. Some of today’s CAD packages allow engineers to request a quote for making a design using a selected manufacturing technique. When the CAD file format is a common format, engineers can immediately connect with suppliers to outsource manufacturing or collaborate on part improvements.

Help products iterate boldly

The process of creating physical prototypes can be time-consuming. Relying on these parts for fit testing, functional testing, or aesthetic decisions, improving designs, or creating new prototypes can extend the design cycle by weeks.

Engineers today are using analysis, CAM, and DFM tools integrated into modern CAD packages and iterating on designs as they identify areas for improvement and automatically update relevant downstream products such as manufacturing plans, inspection documentation, and supplier data.

Augmented reality helps products better

Augmented reality (AR) is increasingly replacing physical prototypes. Today, the design team meeting described above can use a scale model projected onto a conference table, or a scale model projected onto the desktop of each video conference attendee, and a realistic virtual model of the part can help designers make informed aesthetic decisions.

Implement a virtual tour of the product

For a more immersive experience, consider using virtual reality (VR), a technology that allows designers and other stakeholders, such as end-users and marketing professionals, to experience products on a real scale. Some VR models allow you to navigate and manipulate design features. Designers can then incorporate ergonomic and experience feedback before going into production.