At present, the mechanical processing industry and CNC machining industry have undergone some changes with the rise of the Internet. So what happens when the machining industry encounters “Internet +”? Please take 5 minutes to read this article, which may give you some inspiration.

CNC machining is not limited to physical manufacturing

In the past, whenever CNC machining was mentioned, it was considered that various components constituted the core of hardware products. However, with the development of packaging and digitalization, the production and processing technology of parts and components accelerates to transfer to emerging market countries, and the profits of parts and components will be difficult to maintain.

Therefore, the manufacturing industry in developed countries began to pay more attention to packaging by assembling parts, modularizing some functions and systematizing a series of functions to enhance added value.

Modularization is to assemble standardized parts to design products, so as to quickly respond to the diversified needs of the market and meet the differentiated needs of consumers.

In the past, a lot of time and cost have to be paid in the production process. If complex products are assembled through several modules, the problems of diversification and efficiency can be solved at the same time.

However, modularity itself is just a function of products. In the future, the manufacturing industry will pay more attention to systematization and expand new applications and services on the basis of modularization and encapsulation.

If systematization is taken as the leading factor, more added value with “information” function can be obtained compared with parts in the “physical” sense. On the contrary, if we do not control the dominant power of the system, no matter how good the quality and function of the developed parts are, it is difficult to become the dominant player in the market price.

Machining is not limited to mass manufacturing

In developed countries, the mass production manufacturing industry with the object of large-scale has transferred its production base to emerging market countries, and the multi-type and small batch manufacturing industry with the focus on parts customization has gradually become the mainstream.

In the future, under the trend of “mass customization”, the manufacturing industry in developed countries will be customized according to a variety of personalized needs. At the same time, consumers themselves will be able to put their own needs into production.

The popularization of digitalization and information technology has brought about technological innovation. “Mass customization” will minimize the entry threshold of the manufacturing industry, and individuals without factories and production equipment can easily participate in the manufacturing industry.

The lowering of the entry threshold of the manufacturing industry also means that some unexpected enterprises or individuals will participate in the manufacturing industry, which may cause greater changes to the business model.

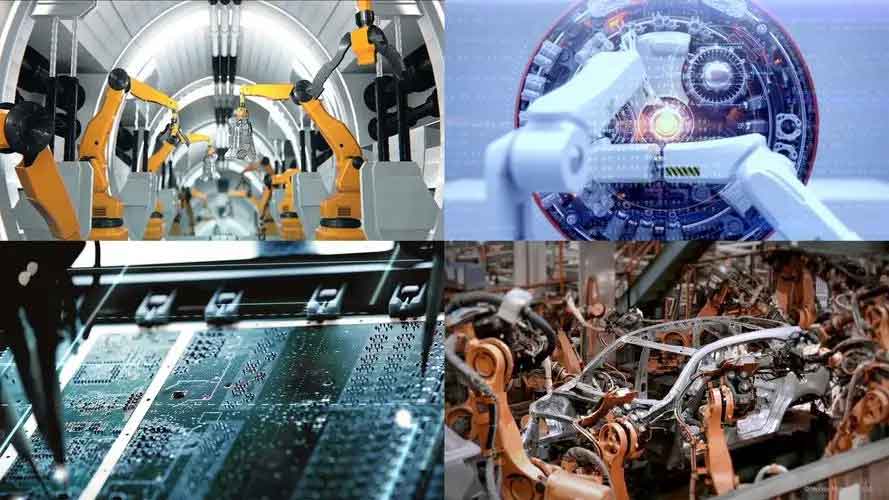

Combination of CNC processing and interconnected manufacturing thinking

Many products around us have begun to enter the network and can access the Internet. “Internet manufacturing” represents the dominant power to control the network. Moreover, from the perspective of network externalities, the enterprises that take the lead in controlling the dominant power will obtain the interests of pioneers for a long time.

With the popularization of information technology, Internet and e-commerce, the new requirements of manufacturing market competition have changed. On the one hand, CNC processing enterprises and machinery manufacturing enterprises are required to continuously obtain information based on the network and make rapid responses to market demand in a timely manner; On the other hand, manufacturing enterprises are required to integrate and share various resources and make rational use of various resources.

Internet manufacturing can quickly respond to market changes, rapidly allocate manufacturing resources through rapid restructuring and dynamic collaboration of manufacturing enterprises, improve product quality, reduce the time required for products to be put on the market and increase market share. At the same time, it can also share infrastructure construction costs, equipment investment costs, etc. to reduce operational risks.

In addition, as a future trend, CNC processing factories will realize the networking of internal and external services through the Internet, develop towards the trend of interconnected factories, collect and analyze various information from production workshops, and give feedback to consumers.

The information collected from the factory can be analyzed as big data, which can open up more and new business opportunities. How to process the massive data collected from the workshop through hardware will also determine the value of services and solutions to a large extent.

CNC machining needs the thinking of data manufacturing

In recent years, with the rapid development of Internet, Internet of things, cloud computing and other information and communication technologies, the soaring volume of data has become a severe challenge and valuable opportunity for many industries. The information society has entered the era of big data. The emergence of big data is changing the way people live and work and the operation mode of enterprises.

With the progress of manufacturing technology and the popularization of modern management concepts, the operation of manufacturing enterprises increasingly relies on information technology, so that the entire value chain and product life cycle of the manufacturing industry involve a lot of data, and the relevant data also shows an explosive growth trend.

With the development of mass customization and network collaboration, manufacturing enterprises also need to receive personalized customization data from many consumers online in real-time, and allocate resources, organize production, and manage more relevant data in subsequent links through network collaboration.

The huge value that big data may bring is being recognized by traditional industries. Through technological innovation and development, as well as the comprehensive perception, collection, analysis and sharing of data, it provides a new way for enterprise managers and participants to view the manufacturing value chain.