G41 and G42 are critical cutter compensation codes used in CNC machining, designed to automatically adjust the toolpath to account for the tool’s radius. Although these codes are more commonly associated with CNC milling, they also play a significant role in CNC turning, especially in profiling or contour turning operations.

- G41: Tool Nose Radius Compensation – Left

- G42: Tool Nose Radius Compensation – Right

These G-codes ensure accurate machining by adjusting the toolpath to account for the tool nose radius, which is essential for achieving precise cuts and finishes. This guide will explain the functions of G41 and G42 and provide a step-by-step workflow for their implementation in CNC turning operations.

What Are G41 and G42?

- G41: Cutter compensation left – the tool moves to the left of the programmed path, based on the direction of movement.

- G42: Cutter compensation right – the tool moves to the right of the path.

These codes allow for precise control of the final workpiece dimension, especially when using different insert radii or resharpened tools.

When to Use G41 and G42 in Turning

In CNC turning, G41 and G42 are typically used when:

- Machining external or internal contours where precise dimensions are critical.

- Compensating for the tool nose radius during finishing passes.

- Avoiding manual adjustment for tool size changes.

| Compensation | Direction Relative to Tool Path | Common Use Case |

| G41 (Left) | Compensation to the left (outer diameter) | External turning (OD), facing (left side) |

| G42 (Right) | Compensation to the right (inner diameter) | Internal turning (ID), boring (right side) |

How to Use G41 and G42 in CNC Turning

Here’s a step-by-step breakdown of how to apply G41/G42 in your CNC turning program:

Step 1: Define the Tool Nose Radius

- Before using G41/G42, you must enter the tool nose radius into the tool offset table on your CNC machine.

- Example:Tool 1 → Nose Radius = 0.4 mm

Step 2: Choose the Compensation Direction

- External turning (right-to-left) → Use G42

- Internal turning (right-to-left) → Use G41

Always consider the tool approach and direction of travel.

Step 3: Insert G41/G42 into the Program

- Insert G41 or G42 before the start of contouring. Activate it on a linear move (G01).

Step 4: Cancel Compensation with G40

- After finishing the contouring, cancel the compensation to return to normal programming.

Common Mistakes to Avoid

- ❌ Forgetting to input tool nose radius in the offset table.

- ❌ Activating G41/G42 on a rapid move (G00) instead of G01.

- ❌ Not canceling with G40, which can lead to unintended tool paths.

- ❌ Using the wrong direction code (G41 vs G42) for internal vs. external turning.

Conclusion

If you’re using the SC-CNC series training lathes, you’re in luck—these machines support G41/G42 logic and come with preset tool compensation parameters in their CNC controllers, making them perfect for beginner to intermediate training programs.

Mastering G41 and G42 in CNC turning is crucial for ensuring precision, consistency, and tool adaptability. Whether you’re programming for prototyping or mass production, understanding and properly applying cutter compensation is an essential skill every CNC turner should develop.

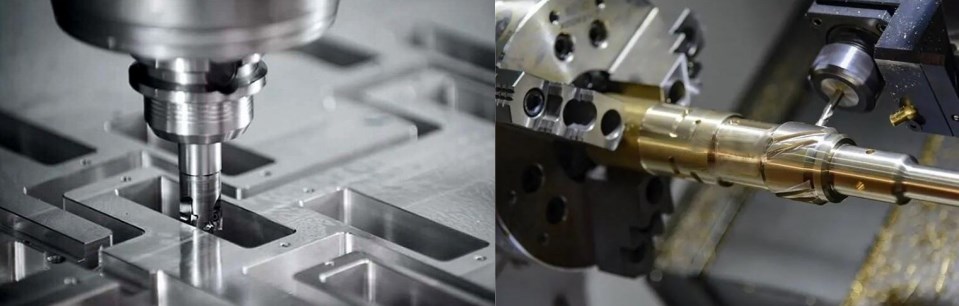

Our CNC Machining Capabilities

Application Industry

Motorcycle manufacturing

Motor manufacturing

Car manufacturer

Internal combustion engine production

Oil pump manufacturing

Instrument