The strong manufacturing capabilities in modern industry are attributed to the continuous improvement of our industrial manufacturing technologies. We started producing crafts by melting and cooling metal almost two hundred years ago. Now we got CNC machining and 3D printing, no one ever has to worry about his/her extremely sophisticated design not being able to be made through technologies of this age. What we should pay attention to is money, money and money. So, how could you reduce the cost if you choose CNC machining for your project? In this article, I’ve listed some factors that might affect the cost of CNC machining, and some tips to help you reduce them.

A Brief Introduction – What Is CNC Machining And How It Works

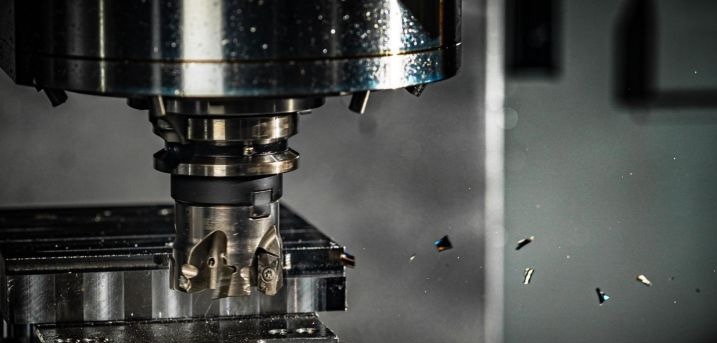

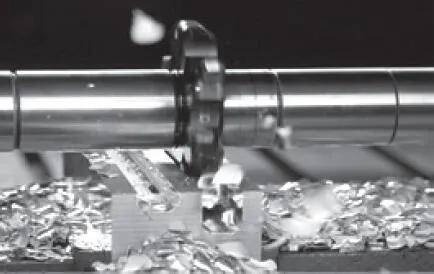

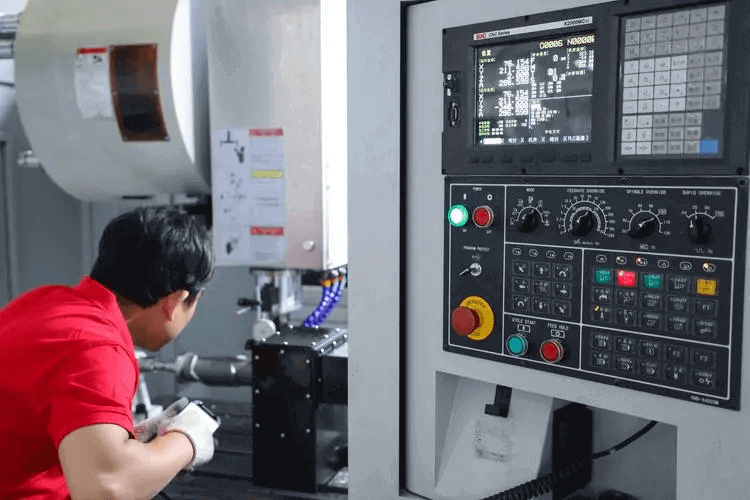

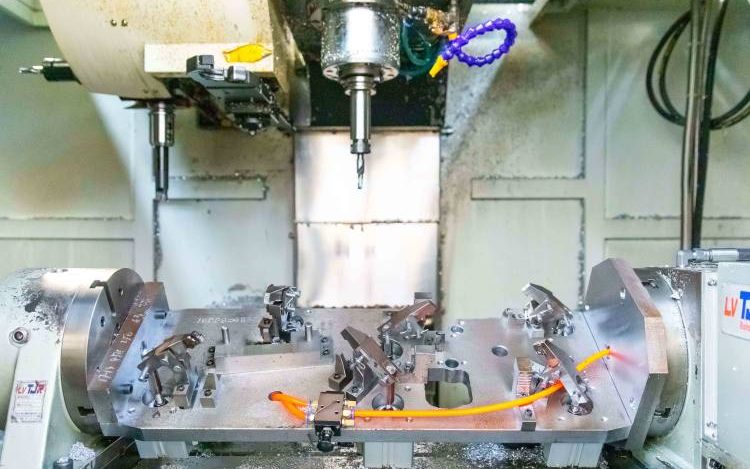

Everything begins with what it is. CNC machining is one of the most commonly used manufacturing methods in modern industries. It uses computer software to control different machining tools (cutting tool, driller, router, etc.) and processes the parts into designed shapes. The key feature of the CNC machining process is automation. It speeds up the production and creates great accuracy.

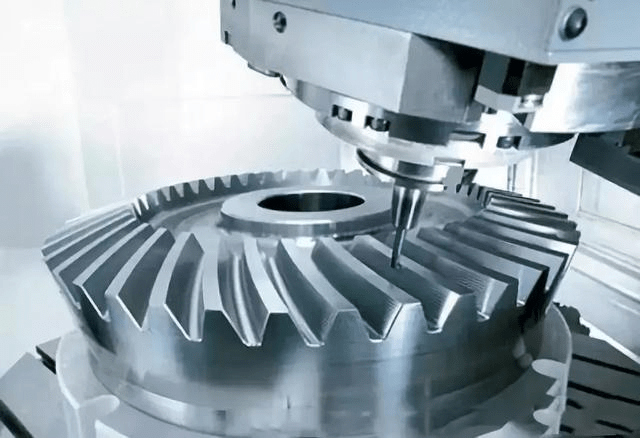

Nearly all materials we use to make parts can be processed by CNC machining. Consequently, this manufacturing process has been applied in almost every industry related to our daily lives – automotive, construction, aerospace, medical, military, etc. Not to exaggerate, but part of our industry is built on it. Mostly, CNC machines are divided into 5 types based on the tools it uses – CNC milling machine, CNC lathes, CNC laser machine, CNC plasma cutting machine and EDM. The characteristics and structures of a part shall decide which machine to use.

Back to topic, the cost of CNC machining cannot be just determined as high or low. It’s affected by multiple factors. Before we delve into those factors, let’s consider how the cost of CNC looks like compared to other manufacturing processes.

Is CNC Machining Expensive Compared to Other Manufacturing Methods?

By other manufacturing methods, I selected 3D printing and metal casting. Metal casting is thought to be an ancient manufacturing process for our time, while 3D printing is considered to be cutting edge. CNC machining happens to be invented in the 1940s – in the middle of the other two births. So I deem it very interesting to make a comparison of them.

After some research and query with our engineers, I found this question to be complex. Again, the cost of a certain manufacturing process varies for many factors like production volume, parts complexity, material, etc. I’ve created a table below whether a certain process is cost-efficient or not, under different conditions.

| Cost-efficient or not | CNC Machining | Metal Casting | 3D Printing |

| Large-volume Production | Yes | Yes | No |

| Low-volume Production | No | No | Yes |

| High Degree of Product Complexity | No | Yes | Yes |

| Low Degree of Product Complexity | Yes | Yes | No |

| Raw Materials | No | No | No |

| Big Size Parts | No | Yes | No |

| High Tolerance | No | No | Yes |

| Low Tolerance | Yes | Yes | No |

To be noticed, There are many materials that 3D printing or metal casting cannot process yet. And there are other factors like surface finishing options affecting the cost, which are not showing above, but you will roughly have your idea by now.

If you look closely at this table, you’d probably find out that 3D printing is suitable for highly complex parts production at a low volume. On the other hand, metal casting is good for mass production. CNC machining, interestingly, comes in at the middle again.

What Might Cause The Price of Machining to Go High?

I believe you’ve made up your mind on which manufacturing process to choose. If you decide to process your parts by CNC machining, you’d like to know how to reduce your cost and keep your project on budget. Here I’ve listed what might cause the price of CNC machining to go high. Stay tuned.

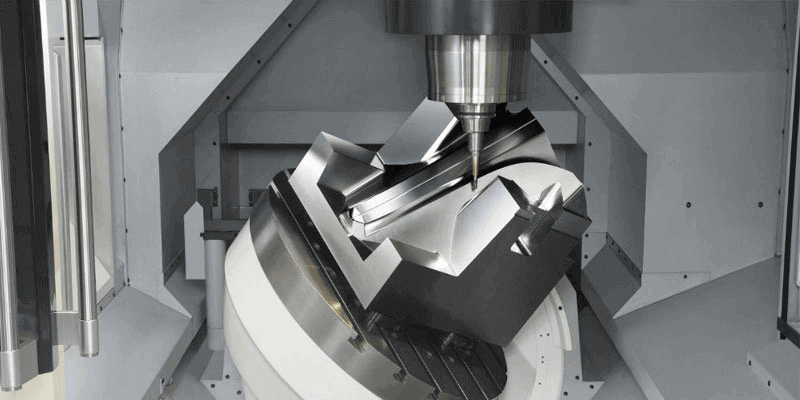

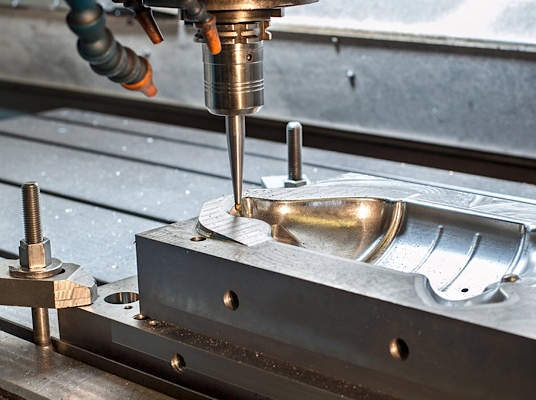

1. The degree of parts complexity

This is probably the most significant factor that affects the cost of CNC machining. A higher degree of complexity will force the machining service provider to choose a machine with more axis, which means higher capital costs. Producing a complex part also significantly increases processing time. A CNC machining company considers time as an important factor when quoting the price.

2. Material

This is a factor that I won’t be paying much attention to cause I can’t just change the whole project merely to reduce some production cost. If the material of my parts happens to be expensive when processed by CNC machining, I might just accept the inevitable fact.

3. The volume of production

We know that the volume of production will affect the cost of this manufacturing process, but how? You might hear the words “start-up cost” and “marginal cost” before. The former means the initiation cost of a process while the lattter stands for the subsequent individual processing cost for each part. For instance, metal casting is a process that’s very high in start-up cost but low in marginal cost, meaning it’s a good solution for large volume production but not a good one for prototyping. This also applies to CNC machining. CNC Machining is got quite a start-up fee as well. If you want to average out this cost in subsequent production, you better have more than just a few parts to produce.

4. Post-processing Options

If you choose a one-stop service to produce the parts, you should consider how to post-process your products. The cost of surface finishing is often lower for simpler processes.

Optimize Your Design

We’re done with the Influencing factors of CNC machining cost. Now let’s focus on how to reduce them. The first thing you need to consider is optimizing your design. The complexity of a part may be unavoidable, but you can adjust some design details to make it more suitable for CNC machining, thus reducing production time. The tips include avoiding internal vertical edges (by adding undercuts or other methods), avoiding over-thin wall, designing the holes in a standard size, avoiding too-deep cavity and avoiding high aspect ratios. There are actually more details to pay attention to. If you are interested in optimizing your design and getting your parts CNC machined, you can talk with a professional designer by getting a quote.

Choose The Right Material And Surface Finishing Method

There are certain materials that are not very easy to be CNC machined. The best choices for CNC machining are alloy Aluminum, Brass, stainless steel, Titanium and Magnesium. Choosing the right material can save you some money but you should distinguish the priority. Surface finishing cost also varies from one to another. Talk with your designer and choose the best finishing option for your project.

Now you’d probably have a rough idea about how to choose the right processing method and reduce the cost. If you are looking for a CNC machining service provider, you’re welcome to contact us. Other services like metal casting and 3D printing are also available. Feel free to get a quote!