In the process of CNC machining, changing the size, size, position, and shape of the parts according to technical standards and correct parameters is what we often call the machining process. This article will start with our actual work case and introduce how CNC machining can make better parts or products.

The Importance of CNC Machining Processes

The CNC machining process is an important part of the production process, and it also directly affects the entire production process and even the quality of the product. Therefore, the machining process is very important.

The machining process must follow the manufacturing technology, and the production process needs to be determined according to the actual situation. The processing technology specification mainly introduces new products and changes technology and equipment. In many cases, the process specification for processing also includes each program and routing.

Most of the mechanical equipment is mainly large-scale equipment, and the actual production needs to be considered when assembling the mechanical equipment. In the process of machining, every link needs to ensure its scientific rationality and avoid safety production problems caused by improper use of equipment. The use of mechanical processing technology can effectively monitor the operation of mechanical equipment in an all-around way and can detect mechanical faults in time, and have the ideal management and technical personnel to find and repair them in time.

If the formulation of the machining process is reasonable, it can effectively improve the efficiency of mechanical production. The combination of improving the machining process and the actual situation of its manufacture will help to realize the modernization of the machine and effectively improve the accuracy and tightness of the machine manufacturing.

How to Optimize The CNC Machining Process?

Reduce machining error rate: In the process of machining, the error rate of machining will have a serious impact on the quality of the product. Therefore, it is necessary to reduce the machining error rate when performing machining optimization.

In general, the machining error rate occurs in the primary stage of product processing, which is also the design stage. Therefore, as a designer, we should analyze the problems existing in the design through scientific algorithms and reasonable planning to minimize the generation of error rates.

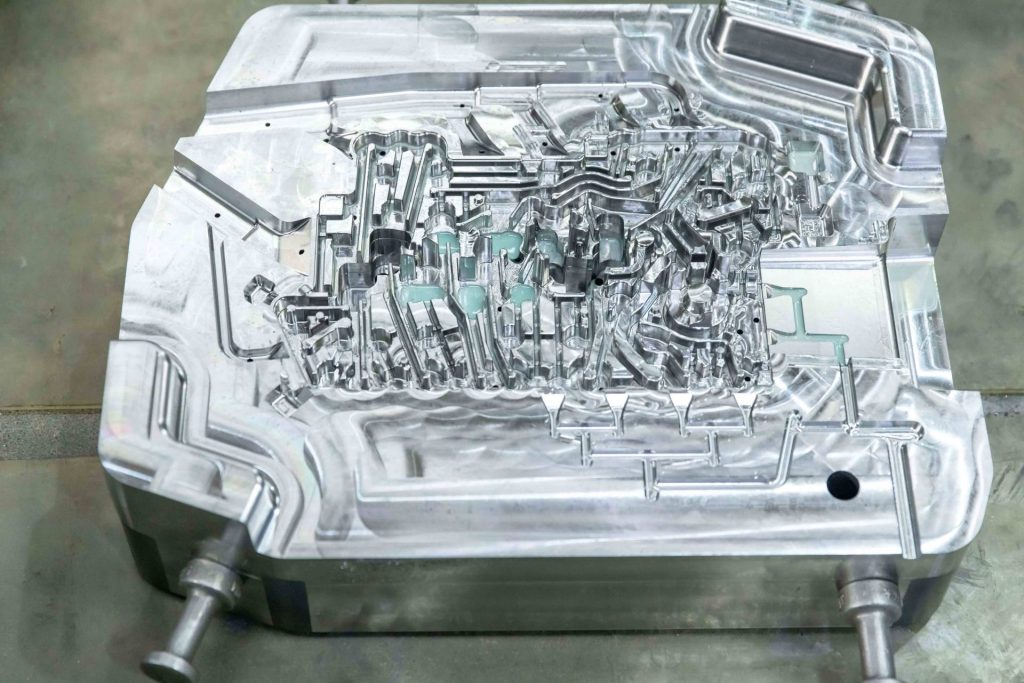

Select the optimal machining process route: The machining process route is a very important part of the machining process. To reduce the impact on the environment in the production process. We have to formulate the machining process route according to the actual situation.

In the process of formulation, factors of production efficiency and finished lamps should be considered, and the surrounding environment and resources should also be considered. To improve the efficiency of mechanical processing in an all-around way and protect the environment, to achieve sustainable development.

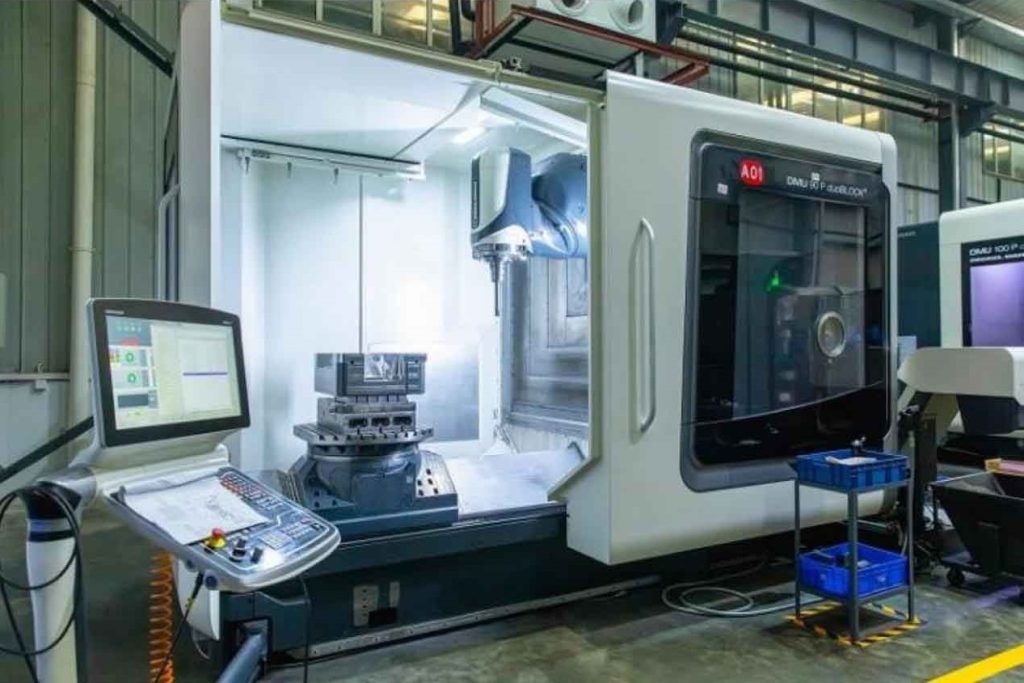

Improve the production efficiency of mechanical processing equipment: The realization of mechanical processing technology mainly depends on processing equipment. At the same time, machining equipment is also an important process in the production of mechanical products.

For the rationalization of mechanical processing equipment, equipment should be selected according to the actual situation, and advanced equipment at home and abroad should be introduced to provide a basis for the realization of high-level processing technology.

Why does JTR Always Optimize Our Machining Solutions?

Machining technology is mainly the mechanical operation behavior in the process of machinery manufacturing. With the continuous improvement of the technical level of mechanical processing technology, the processing technology of JTR is also developing rapidly. The progress of CNC processing technology leads us to improve our competitiveness.

Therefore, we can not only meet customers’ needs for parts customization and product correction through traditional CNC machining technology but also strive to create a variety of machining solutions to solve more problems in customer product customization.