In the production of tires, the tire mold is one of the most important parts. The quality of the tire mold surface directly affects the appearance, production efficiency, and service life of the tire. Doing a good job in the surface treatment of tire molds and improving the surface quality of tire molds can effectively prolong the service life of tire molds and improve the processing quality of tires.

What is a tire mold?

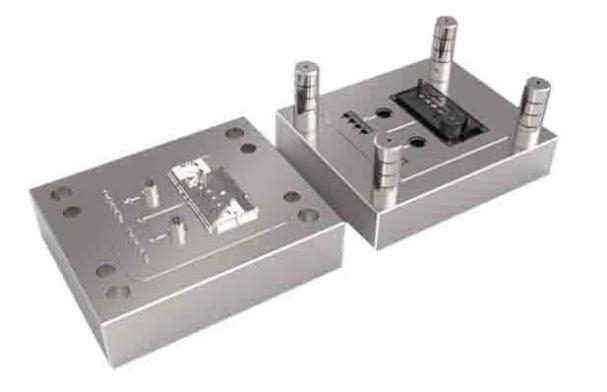

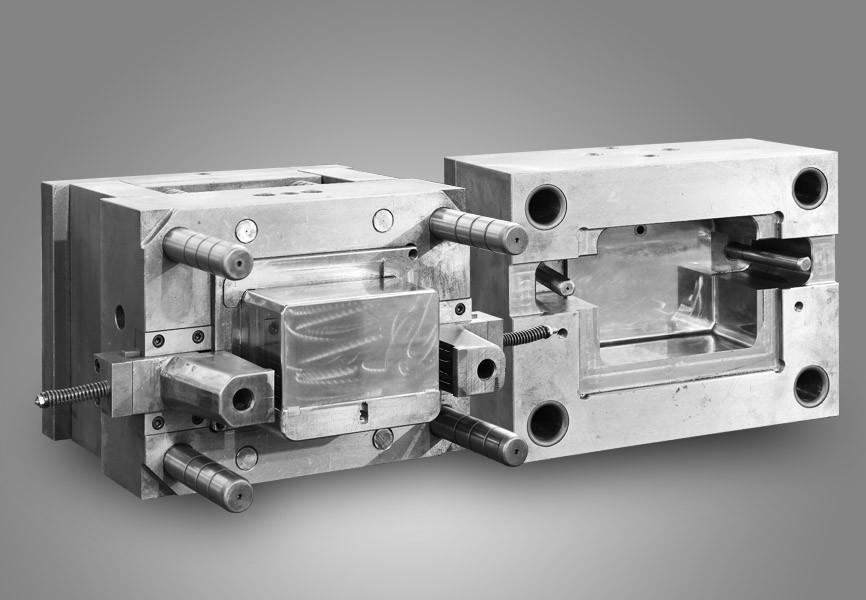

Tire molds are molds used for vulcanization molding various types of tires. Tire molds are divided into 2 types: active molds and two-half molds.

The active mold is composed of the pattern circle, mold sleeve, and upper and lower side plates.

The two-half mold is composed of an upper mold and a lower mold.

What are the reasons that affect the surface quality of tire molds?

Insufficient protection of tire mold surface

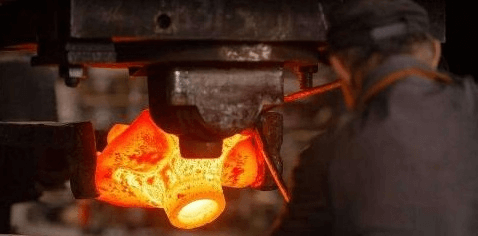

In order to ensure the service life of the tire mold, a thin but relatively dense surface hardening layer is plated on the surface of the tire mold after the tire mold is processed and manufactured. Taking the aluminum alloy material as an example, the hardened layer used on the surface is mainly an oxide film, and the surface of the steel tire mold is mainly a metal hardened layer.

The metal hardened layer on the surface of the tire mold can make the finished tire form a beautiful surface layer on the surface. However, with the long-term use of the tire mold, the sulfide in the tire oozes out and adheres to the surface of the tire mold, which will cause serious erosion to the surface of the tire mold. And it results in the appearance of the tire processed by the tire mold getting worse and worse. Thus affecting the service life of the tire mold.

There are defects in the cleaning method of the tire mold surface

After the tire mold is used for a long time, rubber particles or sulfides will adhere to the surface of the tire mold and affect the processing quality of the tire. At this time, the surface of the tire mold needs to be treated.

Nowadays, the surface treatment of tire molds mainly adopts the mechanical cleaning method, the chemical cleaning method, dry ice or laser, and other methods.

- The mechanical cleaning method adopts manual abrasive cloth or steel wire physical grinding and dries sandblasting. Different combinations can be selected for cleaning according to needs. Mechanical cleaning is a mature technology that is widely used by the tire industry. The advantage is that it is simple and easy to implement, and the requirements for equipment and tools are not high. The disadvantage is that it will cause mechanical damage to the mold and shorten its life of the mold. Sandblasting is easy to block the vent holes of the mold. After sandblasting, it takes a lot of work to clear the vent holes, and the cleaning cycle is long.

- Chemical cleaning methods mainly include the organic solvent method, melting method, acid cleaning method, alkali cleaning method, etc. Although these methods are convenient to use, the cost is low. However, the long-term use of the above method will cause mold corrosion, which directly affects the appearance and quality of the product. At the same time, these raw materials pollute the environment and damage the health of workers.

- For the sulfides attached to the surface of the tire mold, by spraying dry ice carried by compressed air on the hot mold surface at high speed, the sulfides attached to the surface of the tire mold can be rapidly vaporized and volatilized. Treating tire molds with dry ice can be used as an auxiliary measure but not as a primary clean-up measure.

- Laser cleaning technology is to make the mold absorb a specific wavelength of laser light, the energy is very small, and will not cause damage. Dirt on the mold surface (sulfide, inorganic oxide, silicone oil, carbon black, etc.) absorbs a lot of energy, is instantly expanded, vaporized and evaporated, and taken away from the mold surface, so as to achieve the effect of cleaning. Laser cleaning technology is a new technology based on the interaction effect of laser and matter, which is pollution-free, noise-free, and harmless to the human body and environment. Although laser surface treatment has a good effect on the surface treatment of tire molds, the investment is large and the cost is high, so the laser cleaning process is not widely used.

How to improve the surface quality of tire molds?

The surface quality of the tire mold has an extremely important influence on the processing quality, performance, and service life of the tire. The surface quality of tire molds can be improved by the following methods:

1. Nano-permeable layer treatment is performed on the surface of the tire mold.

After the surface protection treatment of the tire mold, there are still many very fine holes on the surface of the tire mold. These holes cannot be seen with the naked eye, but the diameter of these holes is larger than the size of the macromolecules of the rubber compound used in the tire manufacturing process. These holes will result in a portion of the macromolecules of the compound being embedded in the holes on the surface of the tire mold during the vulcanization and manufacture of rubber tires. These molecules will continue to increase with the processing of the tire, and cause the surface of the tire mold to lose its smoothness, which will seriously affect the surface quality of the tire mold and ultimately the surface of the manufactured tire.

This problem can be solved by nano-permeable layer treatment on the surface of tire mold. Through a special treatment process, the nano-metal material is infiltrated into the small holes existing on the surface of the tire mold, thereby filling the holes that cannot be observed by the naked eye on the surface of the tire mold. Therefore, the macromolecules of the rubber compound cannot penetrate into the holes on the surface of the tire mold during the tire vulcanization process, and the use efficiency and service life of the tire mold are improved. At the same time, it can effectively improve the surface finish of tire mold and the ability of anti-corrosion and anti-wear. It is an important application of new tire mold surface treatment technology.

2. Combination-piece pattern circle technology

Aiming at the problem that the exhaust holes of the tire mold are easily blocked and affect the surface quality of the tire, it can be solved by using the combination-piece pattern circle technology. The combination-piece pattern circle technology divides the tire mold into a plurality of small units according to the tire pattern so that the exhaust gas generated during the tire vulcanization process can be discharged through these small gaps. This can prevent the accumulation of exhaust gas from affecting the quality of the tire surface.

As a professional mold maker, JTR has always paid attention to various new manufacturing and processing technologies. We hope that customers who have mold manufacturing needs or mass production needs can contact us at any time, and we will provide professional personnel to provide you with high-quality services.