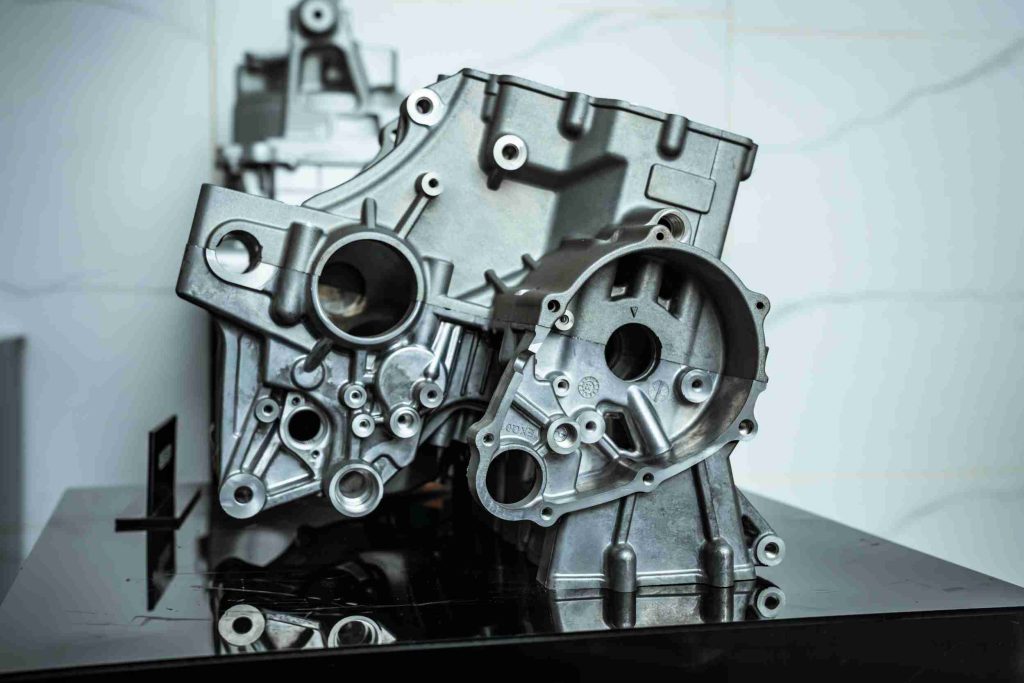

In modern industrial production, high-pressure die-casting technology is widely used in many fields such as automobiles, aerospace, and electronics. High-pressure die-casting relies on injecting liquid or semi-liquid metal into the mold cavity under high pressure to obtain precision castings. The mold is crucial in this process and determines the shape, dimensional accuracy, and surface quality of the casting. The life of the mold is affected by many factors, including processing technology and use environment. However, material selection is a basic and extremely critical factor, which directly determines the performance of the mold under harsh working conditions such as high temperature, high pressure, and high speed. Therefore, in-depth research on how to improve the life of high-pressure die-casting molds through material selection is of great practical significance.

Understanding High-Pressure Die Casting Dies

The working environment of high-pressure die-casting molds is like an extreme battlefield, facing many severe challenges. In this special working scenario, the various conditions that the mold is subjected to are complex and harsh, which puts very high demands on the performance of the mold material.

Working Environment Characteristics

During the high-pressure die-casting process, the mold faces an extreme working environment.

The first is the high temperature environment. When the die-casting metal (such as aluminum alloy, zinc alloy, etc.) is in liquid state, the temperature can often reach several hundred degrees Celsius. Taking aluminum alloy die-casting as an example, the temperature of liquid aluminum alloy is usually around 600-700°C. Such high temperature will cause the mold surface to heat up rapidly.

The second is the high-pressure environment. During die-casting, a very high pressure needs to be applied, generally ranging from tens of megapascals to hundreds of megapascals. This high pressure will produce huge stress on the mold cavity.

The third is high speed. Liquid metal fills the mold cavity at high speed under high pressure, which is like the scouring of the river channel by high-speed water flow, causing strong scouring and wear on the surface of the mold cavity.

The working environment of high-pressure die-casting molds is full of extreme conditions such as high temperature, high pressure and high-speed flushing. These special working conditions clearly define the performance requirements of mold materials such as high temperature resistance, high pressure resistance and wear resistance, which also provides us with basic considerations when choosing suitable mold materials.

Requirements for material properties

- High temperature resistance: The mold material must maintain good strength, hardness and stability at high temperatures. At high temperatures, if the strength and hardness of the material decrease too quickly, the mold is prone to deformation. For example, when the high temperature strength of the mold material is insufficient, the mold cavity may collapse partially under the high pressure during the die casting process, thus affecting the dimensional accuracy of the casting. In addition, the stability of the material at high temperatures is also important, including a small thermal expansion coefficient to prevent mold cracking due to excessive dimensional changes caused by thermal expansion and contraction.

- High pressure resistance: The mold material should have sufficient compressive strength to withstand the high pressure during the die casting process without cracking or breakage. If the compressive strength of the material is not enough, micro cracks will appear inside the mold under high pressure, and these cracks will gradually expand as the number of die castings increases, eventually leading to mold failure.

- Wear resistance: Due to the high-speed scouring of liquid metal, the mold material must have good wear resistance. If the wear resistance is insufficient, the surface of the mold cavity will wear out quickly, which will not only affect the dimensional accuracy of the casting, but also reduce the demoulding performance of the mold, making it difficult to smoothly remove the casting from the mold.

The characteristics of the working environment of high-pressure die-casting molds determine that the materials must have multiple properties. Understanding these requirements is the premise of reasonable material selection. Only materials that meet these performance requirements can increase the life of the mold.

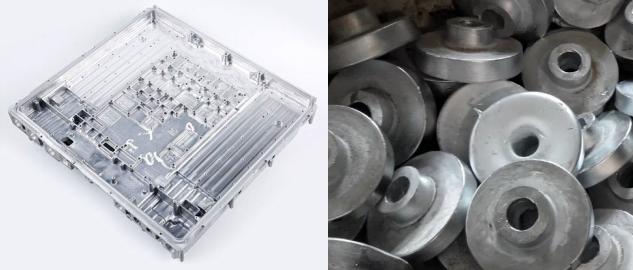

Common High-Pressure Die-Casting Mold Materials and Their Characteristics

| Material | Description | Advantages | Limitations |

| H13 Steel | A hot work tool steel with a composition of C (0.32-0.45%), Si (0.80-1.20%), Mn (0.20-0.50%), Cr (4.75-5.50%), Mo (1.10-1.75%), V (0.80-1.20%). Its microstructure includes martensite, bainite, and residual austenite. | – Good toughness to withstand impact loads during die casting. – Excellent thermal fatigue resistance for repeated heating and cooling cycles. – Moderate wear resistance for medium-complexity dies. | – Performance drops significantly in extreme high-temperature and high-pressure conditions. – Limited dimensional stability for large, complex, and precision molds. |

| Cemented Carbide | Composed of high-hardness carbide phases (e.g., WC, TiC) bonded with metals like Co or Ni. | – Superior wear resistance and hardness. – Excellent deformation resistance under high pressure. – Ideal for wear-prone areas like gates and runners. | – High brittleness, prone to cracking under impact loads. – Difficult to machine and high cost, limiting its use in large molds. |

| Advanced Ceramics | Materials like silicon nitride (Si3N4) with high hardness, thermal stability, and corrosion resistance. | – Exceptional high-temperature performance. – Corrosion resistance makes it suitable for casting reactive alloys like magnesium. – Low friction for improved demolding performance. | – High production costs and brittleness limit widespread adoption. |

Key Considerations in Material Selection

In the manufacturing process of high-pressure die casting molds, material selection is not an isolated decision, but a complex process that requires comprehensive consideration of many factors. Factors such as the type of die casting alloy, the complexity of the mold, and the expected production scale all greatly affect the choice of mold material.

Casting Alloy Type

Different die casting alloys have different requirements for mold materials.

- Aluminum Alloys: These have relatively high melting points (600–700°C) and require mold materials with excellent high-temperature resistance to prevent thermal fatigue and deformation.

- Zinc Alloys: With lower melting points (400–450°C), the demand for high-temperature resistance is less critical. However, the mold material should exhibit good toughness and wear resistance to accommodate frequent use and mechanical stresses.

- Magnesium Alloys: Magnesium is chemically reactive, so mold materials need superior corrosion resistance to avoid chemical degradation during the casting process.

Mold Complexity

The complexity of the mold design influences material selection:

- Simple Molds: Materials with moderate machinability and sufficient toughness can handle straightforward shapes and lower manufacturing demands.

- Complex Molds: For intricate designs with thin walls or detailed internal structures, mold materials must offer superior machinability for precision manufacturing and high toughness to endure concentrated stress in fragile sections.

Expected Production Scale

The scale of production determines the balance between upfront material cost and long-term efficiency:

- High-Volume Production: Requires robust materials with outstanding wear resistance and thermal stability to endure continuous operation. Although initial costs are higher, these materials reduce downtime and replacement expenses, making them cost-effective in the long run.

- Low-Volume Production: For smaller production runs, materials with moderate durability and lower costs may suffice, prioritizing budget efficiency over extended lifespan.

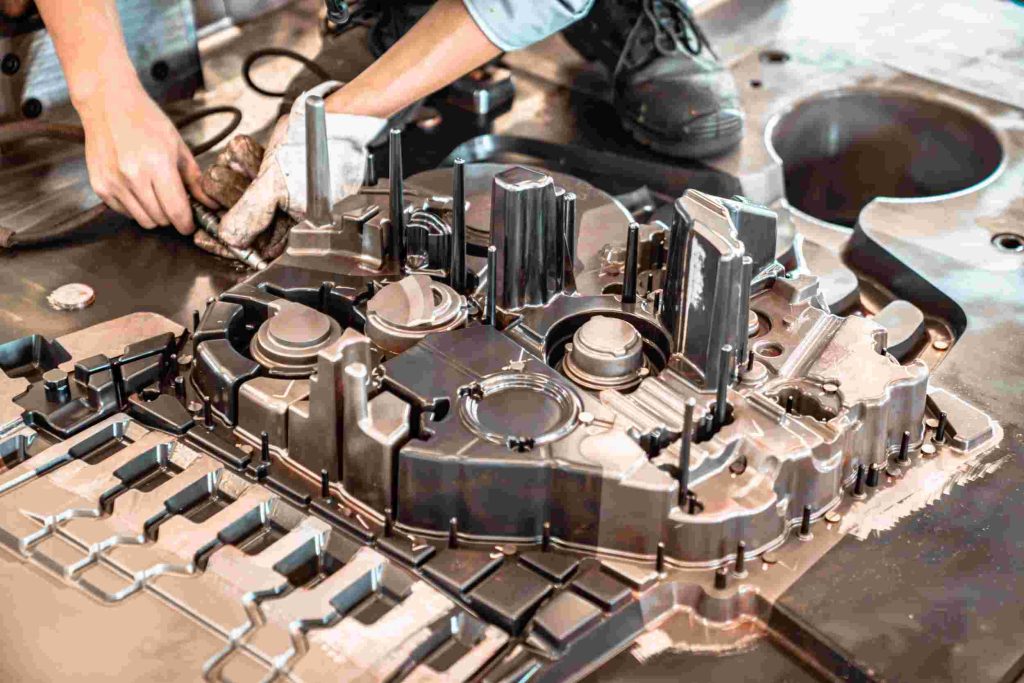

Coordination Between Material Selection and Mold Manufacturing Process

The inherent properties of the material dictate the appropriate manufacturing techniques, while the processes, in turn, influence the material’s performance. This collaborative relationship is a key factor in enhancing mold quality and achieving superior results.

Compatibility of Materials and Processing Technology

Different materials perform best when processed with appropriate manufacturing techniques:

- H13 Steel: Heat treatment parameters like heating temperature, holding time, and cooling rate must be meticulously controlled to ensure an optimal microstructure. Improper heat treatment can degrade its performance.

- Cemented Carbide: Due to its high hardness, specialized tools and methods, such as Electrical Discharge Machining (EDM) or laser machining, are required for shaping. Careful handling is necessary to avoid introducing stress during machining, which could weaken the material.

Enhancement of Material Performance Through Surface Treatments

Surface treatment technologies further enhance material properties, extending the lifespan of molds:

- Nitriding: Forms a hard nitrided layer on the surface of H13 steel, significantly improving wear resistance, corrosion resistance, and demolding performance without affecting the core toughness.

- Coatings (e.g., PVD/CVD): Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) applies wear-resistant and corrosion-resistant coatings, which are highly effective for molds exposed to extreme conditions.

- Shot Peening: Induces compressive stress on the die surface, reducing the likelihood of cracks and enhancing resistance to fatigue.

Incorporating these advanced treatments ensures optimal performance and durability, making molds more resilient to the harsh conditions of die casting.

By correctly selecting high-pressure die-casting mold materials, the performance of the mold can be fundamentally improved, thereby extending the life of the mold. Suitable materials can enable the mold to maintain good strength, hardness, toughness, wear resistance and corrosion resistance in harsh working environments such as high temperature, high pressure and high speed, thereby ensuring the smooth progress of die-casting production, reducing production costs, and improving production efficiency and product quality. JTR as a professinoal casting manufacturer, we have various material for you to choose. Please feel free to contact us for any die-casting or mold making services.