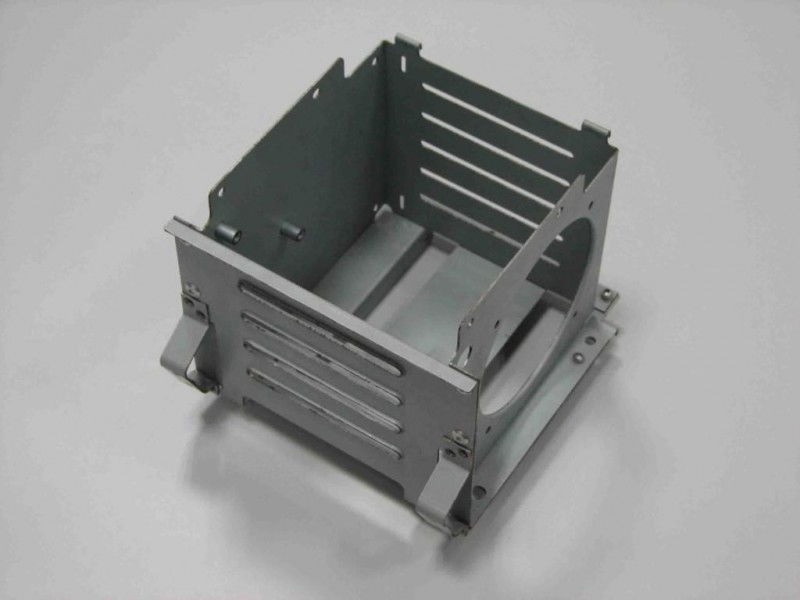

Galvanized sheet metal is a common material used in various construction, manufacturing, and DIY projects due to its durability, corrosion resistance, and versatility. However, cutting galvanized sheet metal requires specific techniques and tools to ensure clean and precise cuts without damaging the material. As a manufacturer that can provide excellent sheet metal fabrication services, JTR will introduce what galvanized sheet metal is, the properties and characteristics it possesses, and provide insights into the best techniques and tips for cutting it effectively.

What is Galvanized Sheet Metal?

Galvanized sheet metal is steel or iron that has been coated with a protective layer of zinc through a process called galvanization. This coating serves as a barrier against corrosion, making galvanized sheet metal highly resistant to rust and other environmental elements. The galvanization process involves immersing the metal in molten zinc or applying a zinc-rich coating through electroplating.

Properties and Characteristics:

- Corrosion Resistance: The zinc coating protects the underlying metal from rust and corrosion, even in harsh environments.

- Durability: Galvanized sheet metal is known for its strength and longevity, making it suitable for outdoor and industrial applications.

- Aesthetic Appeal: The shiny, metallic appearance of galvanized sheet metal adds aesthetic value to structures and projects.

- Weldability: Galvanized sheet metal can be welded, although precautions must be taken to prevent the release of toxic zinc fumes during welding.

How to Cut Galvanized Sheet Metal?

Techniques for Cutting Galvanized Sheet Metal

There are several techniques for cutting galvanized sheet metal, each with its advantages depending on the complexity of the cut, thickness of the metal, and desired finish. Here are some common methods:

- Manual Shearing:

Tin Snips: For straight cuts in thinner gauge galvanized sheet metal (up to about 18 gauge), tin snips are a simple and effective option. They are hand-held shears that work similarly to scissors. They come in straight and offset varieties for different cutting needs.

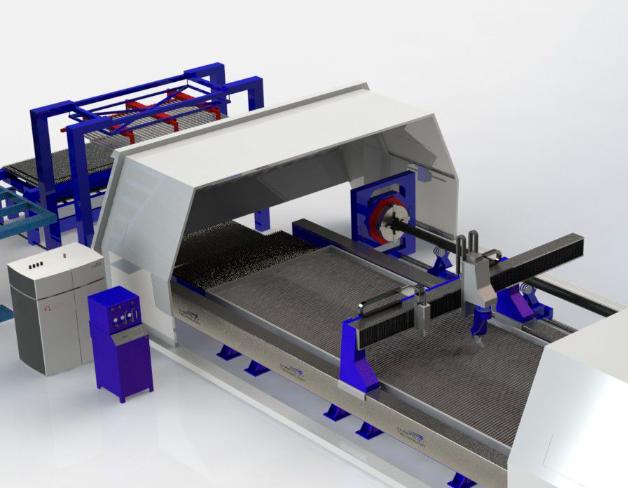

- Power Shearing:

Shear Brakes: For straight cuts in thicker metal sheets (up to about 1/4 inch), shear brakes are powerful machines that use a clamp to hold the sheet and a shearing blade to make clean cuts.

Aviation Snips: These are stronger, motorized versions of tin snips that can handle thicker materials (up to about 16 gauge) and offer more cutting control.

- Machining Techniques:

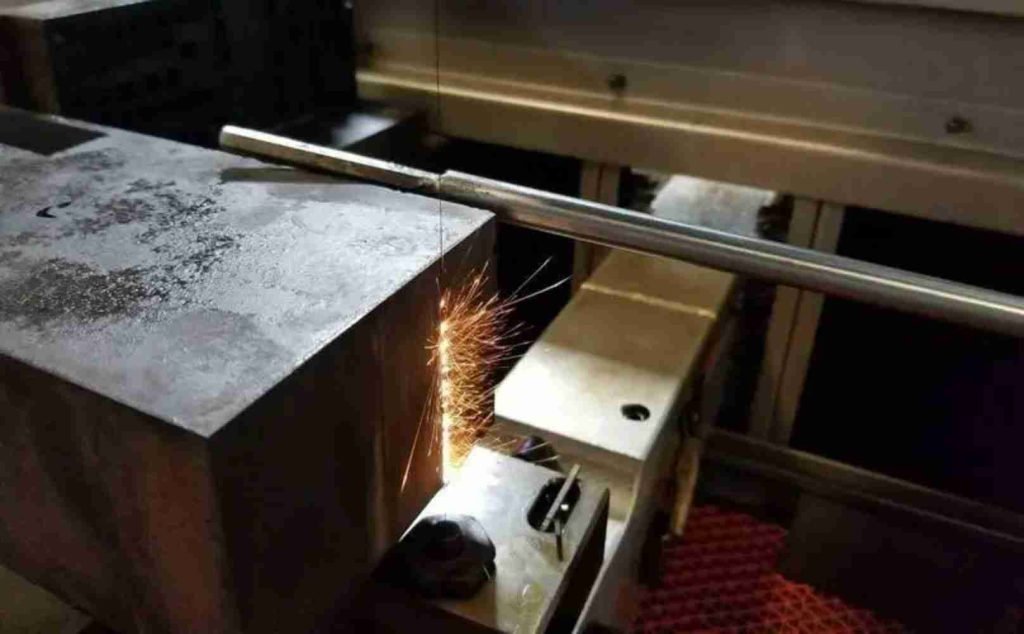

Circular Saw: Can be used with a metal cutting blade to make straight cuts in galvanized sheet metal. However, it can generate sparks and a rougher cut edge compared to other methods.

Jigsaw: With a metal cutting blade, a jigsaw can be used for straight or curved cuts in thinner sheet metal. Similar to a circular saw, it can leave rougher edges.

- Other Techniques:

Nibbler: A nibbler is a power tool that punches out small pieces of metal to create a continuous cut. It’s great for intricate cuts and curves.

Plasma Cutting: This technique uses a superheated plasma torch to melt and blow away metal, allowing for precise cuts on various thicknesses of galvanized sheet.

Laser Cutting: For the most precise and intricate cuts, especially on complex designs, laser cutting utilizes a focused laser beam to vaporize the metal.

Tips for Successful Cutting

- Wear Protective Gear: Always wear safety goggles, gloves, and a dust mask when cutting galvanized sheet metal to protect against sharp edges, flying debris, and metal particles.

- Use Lubrication: Applying a small amount of lubricant or cutting fluid to the cutting tool can help reduce friction and heat buildup, resulting in smoother cuts and prolonging the life of the cutting tool.

- Inspect Cuts Regularly: Periodically inspect the cut edges for burrs or jagged edges and use a file or deburring tool to smooth out any rough spots.

- Dispose of Scraps Properly: Dispose of scrap metal and cuttings responsibly, as galvanized sheet metal may contain hazardous materials such as zinc.

Conclusion

Cutting galvanized sheet metal requires careful planning, the right tools, and proper techniques to achieve accurate and clean cuts while preserving the integrity of the zinc coating. By selecting the appropriate cutting tools and materials, mastering effective cutting techniques, and following essential tips for success, you can confidently tackle projects involving galvanized sheet metal with precision and efficiency. Always prioritize safety and take necessary precautions to ensure a smooth and successful cutting process.