Titanium can be CNC machined like stainless steel; as we all know, it has desirable material properties, and it is also relatively easy to work with. In the early stage of the application of titanium alloy precision casting technology, this process was mainly used to produce medium-sized ordinary precision castings with relatively simple shapes. Most of the castings of this type are within 500mm in size, and most of the shapes are rod-shaped, disc-shaped, plane-shaped, annular, etc. Most of the wall thicknesses are within the range of 6-10mm, such as implanted into the human body. Among them are the prostheses, the blades of the engine, the struts, and other structures. Because there are no complex process structures such as deep grooves, grooves, and ribs, the structural stress during pouring is relatively small, the feeding is relatively sufficient, and the forming process of this type of casting is relatively simple, so the forming quality can always be maintained at higher quality condition. While for Large size titanium CNC machining, perfect machining is not that simple, this article will show you the detailed methods to make perfect large titanium castings.

Before knowing the methods of Precision CNC machining of titanium, first, let’s know the types of large size. As titanium became more popular for its good traits, people began to put it into larger thin-walled complex castings. There are two types of them.

Medium-large Size Titanium Parts

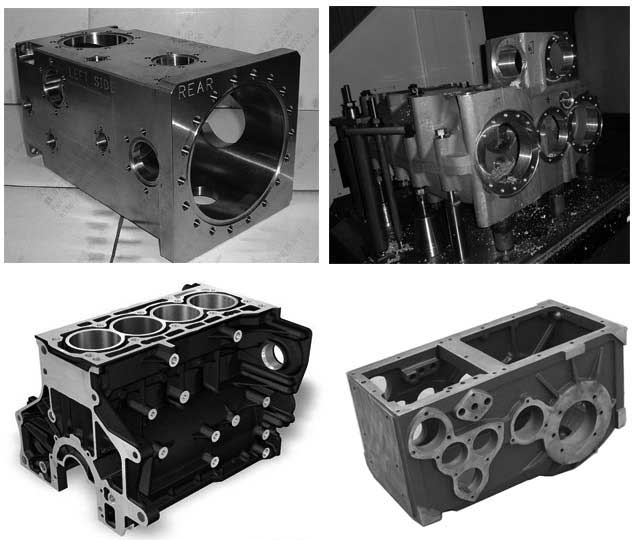

This casting is a type of casting that has been continuously developed to meet the practical application needs of the aerospace industry. With the gradual development of the aerospace field, the application of this type of casting forming technology has become the key research object of various large research institutions. Most of the large-scale thin-walled complex castings are strictly controlled at 500-1000mm in size, with a wall thickness of 1-3mm, and their structure is relatively complex, making it very difficult to form.

Large Size Titanium Parts

Such castings cannot be compared with other castings in every aspect of quality and performance. The size of this type of casting is mostly above 1500mm, the minimum wall thickness is around 1mm, and the mass is mostly around 50-1000kg. This type of casting is often used to replace the structure formed by many fasteners and parts assembly, thereby comprehensively improving the stability and accuracy of the casting structure and significantly reducing costs, and speeding up production.

What’s the Conventional Method to Machine Large Titanium?

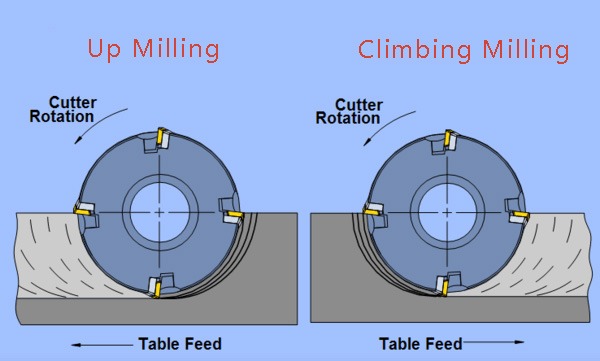

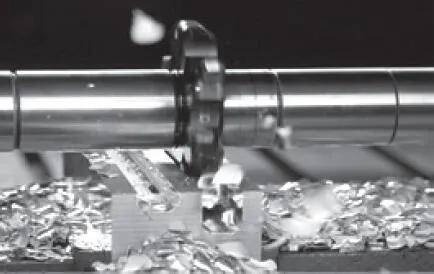

Processes of machining titanium alloys involve conventional machining operations (turning, face milling, high-speed cutting (HSC), milling, drilling), forming operations (cold and hot forming; hydroforming, forging), and alternative machining operations (laser cutting, water-jet cutting, direct metal laser sintering). Machining operations of titanium alloys are considered to be difficult due to their relatively high tensile strength, low ductile yield, 50% lower modulus of elasticity (104 GPa), and approximately 80% lower thermal conductivity than that of steel. The lower modulus of elasticity may cause a greater ‘spring back’ and deflection effect of the workpiece. Therefore, more rigid set-ups and greater clearances for tools are required.

Why is it Difficult to Machine Large Titanium?

The first aspect is the characteristics of large-scale titanium alloy precision castings in terms of part structure. Large-scale titanium alloy precision castings are generally integral frame-type parts. The Z-direction clear height is usually above 650mm, and the area that can be effectively supported inside the component is small. The local rigidity of the part is relatively poor; the surface of the casting has relatively many thin-walled structures, most of the rib thickness is 2-3mm, and the machinability is relatively poor; titanium alloy precision castings generally have four diameter steps. The focal holes and deep groove lugs are very difficult to CNC process, and the construction accuracy requirements such as groove width, coaxiality, and aperture are also very high.

The second aspect is the characteristics of the blank of the casting. Although the blank size of the titanium alloy precision casting has been basically fixed at this stage, it is difficult to control the accuracy error during the forging process of the titanium alloy casting, so it is easy to appear in the subsequent CNC machining process. The following two problems: on the one hand, it is difficult to achieve effective coordination between the non-machined surface and the machined surface, and it is easy to cause processing steps in the processing process, which greatly increases the actual workload of the fitter’s grinding work; on the other hand, it will increase the casting processing. The uneven allowance problem leads to serious castings deformation during CNC machining operations.

The third aspect is the analysis of the deformation characteristics of the parts. If the stress distribution of the large-scale titanium alloy castings is not uniform, it will easily lead to serious deformation problems of the titanium alloy castings. Since most of the large titanium alloy precision castings are semi-closed frame structures, and there are few strong internal supports, the rear end of the precision castings will also show an open structure, the rigidity of the part structure is poor, and there is no reinforcement for the process ribs. Therefore, deformation problems such as open-end tension, height direction dislocation, and profile bending are prone to occur during processing. The main deformation factors include excessive removal of local materials and insufficient release of internal stress; after blank casting, The microstructure distribution of precision castings is not uniform enough, which leads to the problem of unbalanced thermal stress release.

Despite these setbacks, there are techniques that make machining titanium easier.

What’s the Perfect Method to Machine Titanium?

On the basis of the structural characteristics of large titanium alloy castings and the actual processing difficulties, a specific numerical control processing technology plan is formulated, including clamping, rapid positioning, deformation control, and dimensional accuracy control.

Detailed Introduction of Titanium Machining

The first is the application scheme of clamping technology. Since the upper part of the structure of large titanium alloy castings is mostly in a free state, the openings at both ends of the casting and the large holes in the middle have relatively weak rigidity. Usually, vibration problems are prone to occur during machining, which negatively affects the quality of CNC machining. Faced with this problem, you can choose to add three additional sets of adjustable support tooling on the CNC machining platform to effectively enhance the actual rigidity of the CNC machining part of the titanium alloy precision casting to ensure the surface quality and performance of the precision casting during CNC machining. Base.

The second is the fast positioning method. The quick positioning work is to set a fixed positioning pin device on the tooling part of the processing platform and set a position hole structure at the corresponding position of the technical boss of the casting processing to ensure that the hole and shaft clearance can be echoed, so as to achieve fast and accurate positioning during the CNC machining process. . At the same time, the positioning pin at the origin end of the tooling needs to be designed to be cylindrical, and the distal positioning pin needs to be designed to be hexagonal, so as to leave extra allowance for the machining deformation of the casting on the basis of better fixing the precision casting. Lay the foundation for subsequent clamping operations.

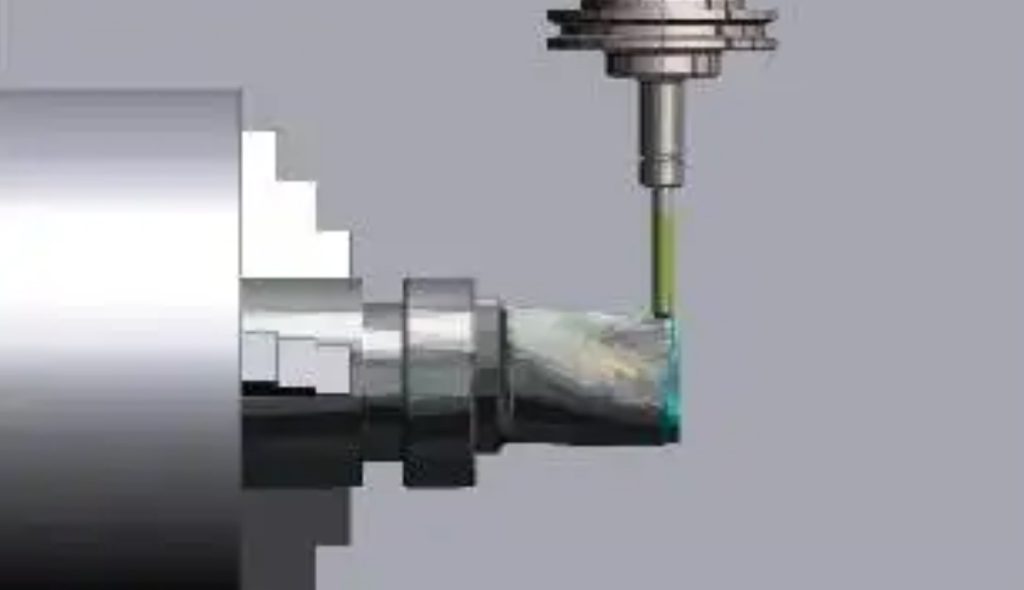

The third is deformation control processing. The optimization of cutting tools and related parameters come first. When cutting precision castings, cutting force is one of the factors that have the greatest impact on the quality of precision castings. The cutting force largely determines the cutting heat and processing deformation of titanium alloy castings and even affects the actual efficiency of cutting. Therefore, in the process of cutting work, a sharp tool with a sharp edge or a relatively large rake angle is usually selected, and a small depth of cut layered processing method is used to reduce the deformation problem of titanium alloy precision castings during the CNC machining process. Probability. The second is the realization of stress-free shaving. Under the influence of various processing stresses, titanium alloy precision castings will have certain deformation problems. In this case, it is necessary to use stress-free clamping and stress-free shaving, and other methods. Reduce the deformation of castings. When the large titanium alloy precision casting is in a free state, the bottom surface of the positioning boss is cushioned by components such as copper gaskets to ensure that the parts are clamped without stress during the pressing operation, and the positioning boss will not be deformed, so as to eliminate the machining process. Clamping stress and casting deformation problems occur in the process.

The fourth is the control scheme of dimensional accuracy. Before the CNC machining work starts, it is necessary to measure the machined surface and the non-machined surface comprehensively so as to facilitate the inspection of the subsequent deformation and machining allowance and determine the machining allowance of the CNC program through the inspection results. In the actual CNC machining process, due to the obvious problem of knife yielding in the thin-walled structure of large-scale titanium alloy precision castings, the CNC machining accuracy of precision castings is easily affected, which eventually leads to local unevenness and size of precision castings. Differences, etc.

Features of CNC titanium parts

- High strength

- Corrosion resistance

- Good strength-to-weight ratio

- Ductility

- Good machinability

- Surface treatment options

- Recyclable

For these reasons, titanium is regularly used in industries like aerospace, automotive, and medical.

The Professional Titanium CNC Machining Manufacturer – JTR

JTR is an experienced provider of CNC machining services and is highly professional in the production of titanium parts and prototypes. Get a free quote now.