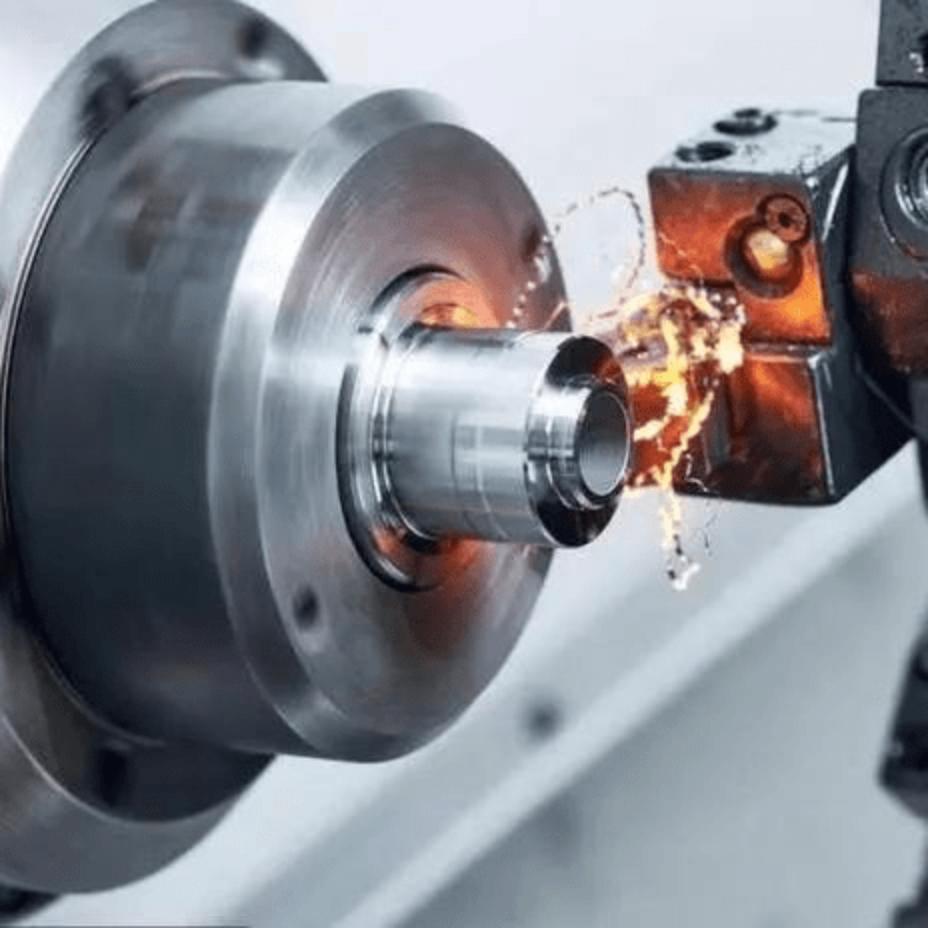

CNC aluminum machining is a precise and efficient process widely used in various industries, from aerospace to automotive and beyond. However, achieving optimal results can be challenging due to the tendency of aluminum to deform during machining. This article explores effective strategies to minimize undesirable deformation and ensure high-quality output.

Characteristics of Aluminum Alloys

Aluminum alloys possess several key characteristics that make them highly desirable for various applications, including CNC machining. Understanding these characteristics is crucial for effectively avoiding undesirable deformation during CNC aluminum machining. Here are some of the key characteristics of aluminum alloys:

- Lightweight: Aluminum is known for its low density, making it lightweight compared to many other metals. This characteristic is advantageous for applications where weight reduction is important, such as aerospace and automotive industries.

- High Strength-to-Weight Ratio: Despite its lightweight nature, aluminum alloys exhibit excellent strength-to-weight ratios. They can withstand significant loads while still being relatively light, making them suitable for structural applications where strength is essential.

- Corrosion Resistance: Aluminum alloys naturally form a thin oxide layer on their surface, providing excellent corrosion resistance against various environmental factors such as moisture, air, and chemicals. This corrosion resistance makes aluminum alloys suitable for outdoor and marine applications.

- Good Thermal Conductivity: Aluminum alloys possess excellent thermal conductivity, allowing them to efficiently dissipate heat generated during machining processes. This characteristic helps in preventing excessive heat buildup and reduces the risk of thermal deformation during CNC machining.

- Ductility and Formability: Aluminum alloys are highly ductile and can be easily formed into various shapes and configurations using different manufacturing processes, including CNC machining, bending, and extrusion. This ductility enables the fabrication of complex components with intricate designs.

- Electrical Conductivity: Many aluminum alloys exhibit good electrical conductivity, making them ideal for applications in electrical and electronic industries where conductivity is crucial, such as in wiring, conductors, and electronic enclosures.

- Non-Magnetic: Aluminum alloys are non-magnetic, which is advantageous for applications where magnetic interference must be minimized or eliminated, such as in electronic devices and equipment.

- Recyclability: Aluminum is highly recyclable and retains its properties even after multiple recycling processes. This characteristic makes aluminum alloys environmentally friendly and sustainable, contributing to the reduction of material waste and energy consumption.

By understanding these characteristics of aluminum alloys, manufacturers and CNC machinists can optimize machining processes to avoid undesirable deformation and achieve high-quality finished aluminum products. Proper selection of machining parameters, tooling, and material handling techniques can help leverage these characteristics to ensure successful CNC aluminum machining operations while minimizing deformation and maximizing efficiency.

Factors Leading to Deformation

Several factors can lead to undesirable deformation during CNC aluminum machining. Understanding these factors is crucial for implementing effective strategies to mitigate deformation and ensure the production of high-quality machined components. Here are the primary factors leading to deformation:

- Thermal Effects:

Thermal expansion: Aluminum alloys have relatively high coefficients of thermal expansion, meaning they expand when exposed to elevated temperatures during machining.

Heat generation: Friction between the cutting tool and the workpiece generates heat, leading to localized temperature increases. Excessive heat can soften the material and cause deformation.

- Mechanical Stresses:

Cutting forces: High cutting forces exerted by the tool during machining can induce mechanical stresses in the workpiece, leading to deformation.

Residual stresses: Residual stresses remaining in the material from previous manufacturing processes or material treatments can contribute to deformation during machining.

- Tooling and Machining Parameters:

Improper tool selection: Inappropriate tool geometry, material, or cutting parameters can result in excessive heat generation, poor chip evacuation, and increased tool wear, leading to deformation.

Incorrect cutting parameters: Inadequate cutting speeds, feed rates, and depths of cut can cause excessive tool pressure on the workpiece, resulting in deformation.

- Material Properties:

Alloy composition: Different aluminum alloys have varying mechanical properties, such as strength, ductility, and hardness, which can influence their susceptibility to deformation during machining.

Microstructure: Variations in the microstructure of aluminum alloys, including grain size and distribution, can affect their machinability and propensity for deformation.

- Workpiece Fixturing and Support:

Inadequate support: Insufficient support or clamping of the workpiece can result in vibration, chatter, and instability during machining, leading to dimensional inaccuracies and deformation.

Inappropriate fixturing: Improper fixturing arrangements may induce distortions in the workpiece due to uneven clamping forces or thermal gradients.

- Environmental Factors:

Ambient temperature fluctuations: Changes in ambient temperature can influence the thermal behavior of the workpiece and machining environment, potentially exacerbating deformation issues.

Humidity and moisture: Exposure to moisture and humidity can affect the material properties of aluminum alloys and contribute to dimensional instability and surface roughness during machining.

By addressing these factors through proper machining techniques, tool selection, material handling, and environmental control measures, CNC machinists can minimize the risk of deformation and achieve precise and consistent results in aluminum machining processes.

How to Minimize Deformation in CNC Aluminum Machining?

Minimizing deformation in CNC aluminum machining requires a comprehensive approach that addresses various factors contributing to deformation. Here are several strategies to minimize deformation during CNC aluminum machining:

- Symmetrical Machining

The key is to avoid the extreme concentration of heat, rather than the loss of manufacturing heat, to reduce the thermal deformation rate.

- Stratified Multiple Machining

If there are several cavities on the aluminum alloy plate, it is easy to twist one cavity wall due to the force distribution. To avoid this, you should treat all cavities at the same time.

- Get an Appropriate Cutting Parameter

The biggest influence on cutting parameters is the depth of cutting back. Maintain efficiency and reduce the number of cuts. CNC milling can solve this problem by increasing the speed of the machine tool and reducing the cutting force.

- Drilling and Milling

When the milling cutter is applied to the cavity and parts, the cutting amount is sufficient. Lead to cutting heat, expansion and deformation. The best way to avoid this problem is to pre-drill with a tool larger than the milling cutter, and then put the milling cutter and the milling cutter together.

- 5 Axis CNC Machining

In five-axis machining, the CNC system moves while cutting five-axis angles at the same time. This machining process is fast and reliable for designing complex parts because the work is close to multiple directions.

The reasons why five-axis machining is widely adopted are as follows:

- The setting is single, which reduces delivery time and improves efficiency

- Because it can avoid collision with the tool holder and tilt the worktable or cutting tool, it has a better geometric shape.

- Shorter and more rigid tools can be used, and some have higher spindle speeds. This is achieved by reducing the load on the tools.

- The workpiece does not pass through different stations, thereby reducing errors, maintaining accuracy and ensuring quality.

Conclusion

Minimizing undesirable deformation in CNC aluminum machining is essential for achieving consistent and high-quality results. By understanding aluminum properties, identifying influencing factors, and implementing effective prevention techniques, manufacturers can mitigate deformation risks and optimize their machining processes. Embracing advanced strategies and technologies further enhances deformation avoidance capabilities, ensuring precision and efficiency in CNC aluminum machining operations.