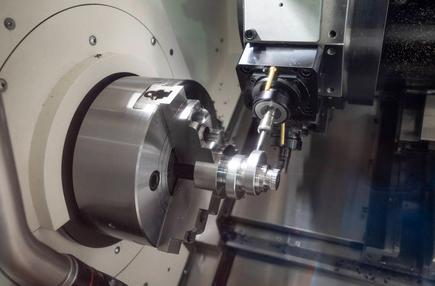

CNC (Computer Numerical Control) machining is a crucial manufacturing method known for its precision and versatility across various industries. From creating small intricate components for electronics to machining large aerospace parts, CNC machining handles a wide range of part sizes. However, the size of the part being machined plays a significant role in determining the overall machining process. This article explores how size impacts every step of CNC machining, from machine selection to costs, helping manufacturers make informed decisions based on part dimensions.

How Size Affects CNC Machine Selection?

The size of the part directly affects the choice of CNC machine required for the job. Smaller components, such as medical implants or precision electronic parts, are typically machined on compact, high-precision tabletop CNC machines. These machines provide the accuracy needed for small parts and are often more efficient for intricate details.

On the other hand, larger parts, like structural components for vehicles or wind turbines, require full-size industrial CNC machines with large work envelopes. These larger machines are designed to handle the weight, bulk, and complexity of machining large components, but they also require more floor space, power, and sometimes even reinforced foundations to support the machining process. Choosing the right machine size based on part dimensions ensures stability, precision, and efficiency.

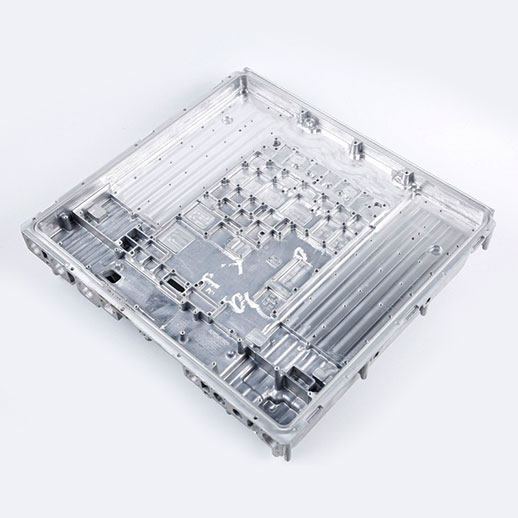

Impact of Size on Precision and Accuracy

Precision and accuracy are vital in CNC machining, but achieving high accuracy levels can become more challenging as part size increases. Smaller parts typically allow for tighter tolerances, meaning that even minor deviations from the specified measurements are minimized. Larger parts, however, are more prone to issues like thermal expansion and slight distortions, which can affect precision over extended surfaces.

Maintaining consistency across larger surfaces requires careful monitoring and control, as even a small discrepancy can lead to noticeable errors on a larger scale. CNC machines designed for large parts often incorporate compensatory mechanisms to maintain precision across expansive areas, but manufacturers need to account for the fact that tolerances may vary depending on the part size.

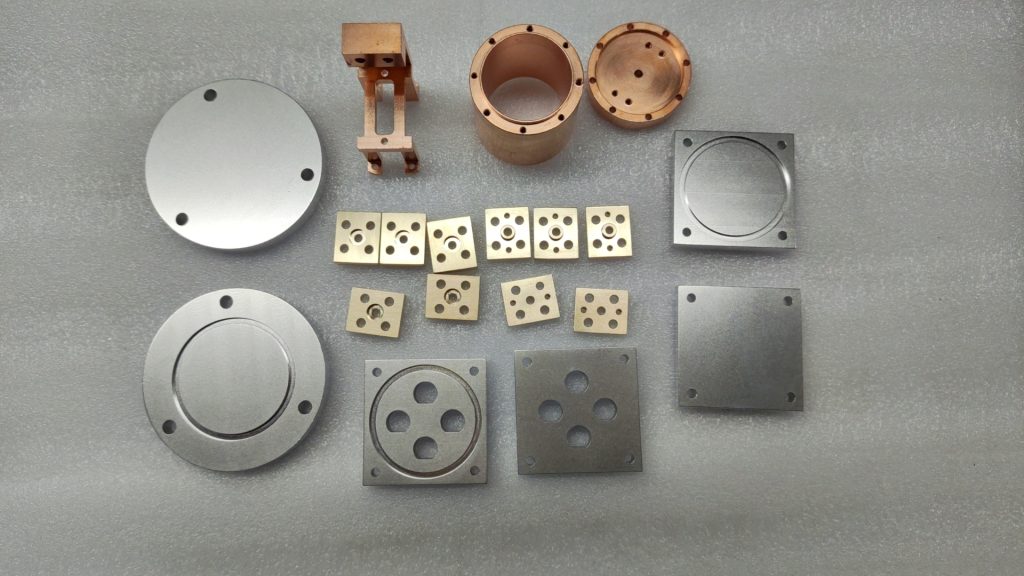

Material Considerations Based on Part Size

The size of the part being machined also influences material choice, as different materials behave differently when machined at various scales. For example, softer materials like aluminum or plastics are often preferred for larger parts because they are lighter and more manageable, reducing the strain on the CNC machine. On the other hand, materials like stainless steel or titanium, which are denser and more challenging to machine, are typically reserved for smaller parts where the strength-to-weight ratio is crucial.

Additionally, the thickness and stability of the material play a role in the machining process. Large parts made from certain metals can undergo stress and warping due to the weight of the material itself or from thermal effects during machining. By selecting suitable materials for the size and application, manufacturers can prevent defects and ensure a stable machining process.

Tooling and Fixture Adjustments for Different Sizes

Proper tooling and fixture design are essential for securely holding the part during machining, and adjustments are often needed depending on the size of the component. Smaller parts may require specialized micro-cutting tools and miniature fixtures to prevent movement or vibration, ensuring precision cuts. Tool size and fixture stability must be scaled to avoid damaging the component or affecting quality.

For larger parts, fixtures must be strong and robust to handle the added weight and to prevent any shifting during machining. Additionally, these larger fixtures may need custom designs tailored to the part’s unique shape and size. Choosing the right tooling and fixtures not only aids in achieving desired accuracy but also prevents potential safety issues that could arise from poorly secured parts.

Machining Time and Cost Factors

Size also influences the time and cost involved in CNC machining. Smaller parts, while requiring precision, typically involve shorter machining cycles, allowing for faster turnaround and reduced material waste. Conversely, machining larger parts often takes longer due to the need for multiple passes, tool changes, and potentially more complex fixturing. Larger parts also demand more raw material, which can increase costs.

Furthermore, larger CNC machines and their maintenance generally have higher operational costs, affecting the total expense of the project. By factoring in the size of the part and the corresponding costs, manufacturers can make informed choices about project feasibility and resource allocation.

Tips for Optimizing CNC Machining for Different Sizes

Here are some tips to enhance CNC machining efficiency based on part size:

- Choose the Right Machine: Match the machine size to the part dimensions, ensuring adequate work area and precision capabilities.

- Tooling Adjustments: Use appropriate-sized tools and select the best material coatings for longer tool life, especially for large parts requiring multiple cuts.

- Optimize Fixtures: For smaller parts, use micro-sized fixtures to secure delicate pieces. For larger parts, ensure fixtures can withstand high pressures and loads.

- Manage Thermal Effects: For larger parts, consider coolant or thermal compensation strategies to avoid warping.

- Preventive Maintenance: Regularly maintain CNC machines to handle varying loads, which is particularly crucial for machines that frequently switch between small and large parts.

The size of a part significantly impacts every aspect of CNC machining, from machine selection to the costs involved. By understanding the unique challenges and requirements associated with different sizes, manufacturers can optimize their CNC machining processes, achieving high-quality results regardless of part dimensions. Considering factors like precision, material selection, tooling, and cost, size serves as a guiding metric that ultimately shapes the CNC machining approach and ensures successful project outcomes. If you have any needs of CNC machining, please feel free to contact us.