How does CNC machining improve auto parts or even auto vehicles manufacturing? Let’s have general learning here. With the continuous popularization of 5G technology to vigorously promote the rapid development of information technology, in this context, the active use of CNC Machining Service to promote the rapid development of China’s traditional machinery manufacturing industry is a positive role in promoting. But on the one hand, must-see though industrial development speed is extremely fast, as the change of market demand, the niche in the small-batch diversified trend, and also improve the quality of the product requirements, also need to have good competition in price, at the same time also need to have more sensitive market sensitivity to respond to market changes.

The emergence of numerical control technology for improving the competitiveness of manufacturing enterprises and the output of high-quality mechanical parts have played an important role, which can be seen in the automatic vehicle manufacturing industry. Using this technology has obvious positive significance and economic benefits.

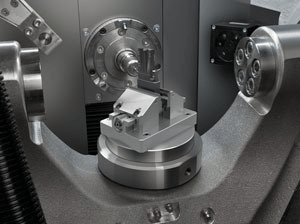

Application of CNC Machining Technology in Auto Parts Production

The traditional machinery manufacturing industry is mainly scale and efficient because only improving the production scale can achieve certain economic benefits. However, under the current market economy conditions, this model appears to be a little inadaptable, or there are more disadvantages. First of all, the main body of the market has changed significantly, people are more personalized, so in this case, the need to use numerical control technology to make the automobile machinery manufacturing can have a small batch of many varieties and respond to the market changes at any time the production goal. Making full use of this technology to make the mechanical manufacturing process can achieve virtual control technology and other related new technologies, and these have provided a technical basis for the further improvement of manufacturing technology.

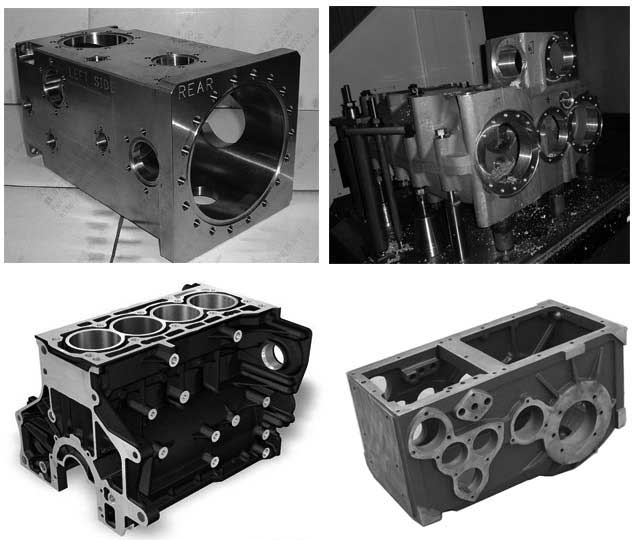

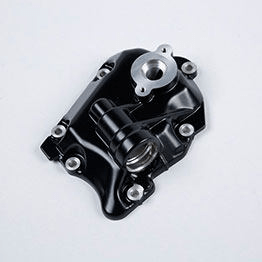

At present, compared with many years ago, China’s automobile engine technology has made significant progress, the reason is that its various internal parts are not only high precision requirements but also extremely complex if it is manufactured in accordance with the traditional process is unable to meet the current market demand will not make such great progress, For example, after the engine cylinder is combined with numerical control technology, the crankshaft has a high degree of balance, especially for many enterprises feel extremely tricky CAM profile accuracy has also reached the relevant requirements. In addition, the cylinder head can also be processed with the help of this technology, whether sealing or its accuracy can meet the actual demand.

In fact, people’s demand for auto CNC is becoming larger than just parts production.

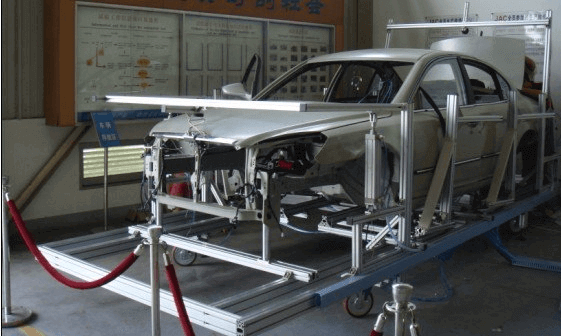

Application of CNC Machining Technology in Vehicle Production

Now in the era of new energy automobile industry in our country can implement corner overtaking, but it is also the priority of basic components to build quite a number of domestic enterprises at present, such as Geely and Changan in achieving large-scale production and have successively opened a number of a different production line, but all without exception are commonly used automatic numerical control technology, For large parts can be directly stamping a molding, in improving the strength at the same time also improve its service life.

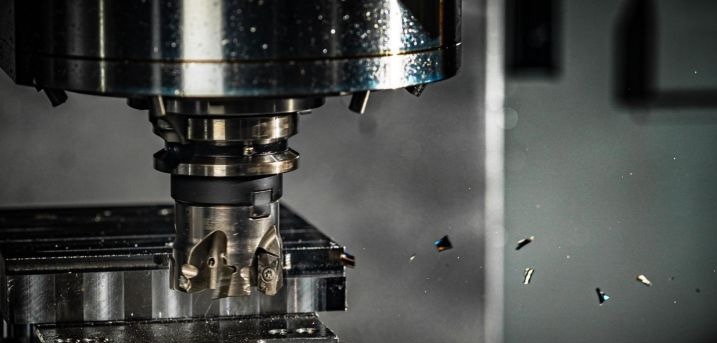

For example, in the current field of new energy vehicle manufacturing, many important components of Tesla can be realized through this technology. In the process of welding and painting, automatic welding and painting can be realized through this equipment, which can reduce manpower expenditure and improve the overall work efficiency and quality. It can be seen that the full application of the technology in vehicle production can realize the automatic operation of the whole process, only need to set up the relevant parameters in advance, not only greatly improve the production efficiency reduce the production cost, but also in quality and quality can be greatly improved. For example, an automobile sales co., LTD in China in recent years, constantly into the advanced technology and equipment, especially the numerical control equipment is used in automobiles and welding automation equipment, in the process of actual use also achieved a good effect, especially welding not only have good performance characteristics of efficiency at the same time also can be used to work in a more extreme environment.

What Does CNC Machining Brings Auto Industry?

- Lower Price but Higher Quality

Current, with the rapid development of the economy in our country and people’s aesthetic temperament and interest, the market needs not only more cars and also want to reflect on the modeling of different personality, so it also puts forward higher requirements on automotive industry not only need to have higher productivity at the same time also need to make timely adjustment according to the changes of the market.

So in the process of production need for wholesale CNC machining car parts for processing and assembling, but the face of fierce market competition also need to make full use of the equipment to improve CNC time and product quality, in providing enterprises with a large amount of income at the same time, also need to further the study of the technology, improve the quality of parts and craft level, To keep abreast of changes in the market and adjust accordingly according to consumer preferences, only by adopting various measures can we achieve higher profits. Therefore, this technology not only has high income and relatively less CNC machining cost but also has more scale compared with the traditional manufacturing process. At the same time, the efficiency and product quality in the production process can be greatly improved, which is also conducive to the multi-level and diversified development of enterprises.

- Safer Production Process

On the one hand, it is necessary to recognize that the use of this technology can greatly reduce labor costs, while automation technology can effectively protect the safety of staff because in the process of production can achieve the separation of staff and mechanical equipment to achieve an ideal production effect. At the same time, in the manufacturing field, if the full use of this technology, so in the case of a safety accident, the control unit can be received according to the information screening, and then issued an alarm message. This plays an extremely important role for the staff to take measures in time and also effectively protects the personal safety of the on-site workers to a certain extent.

Choose a Reliable CNC Machining Company

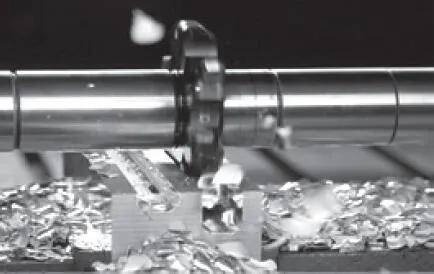

JTR, as one of the most professional CNC machining manufacturers, can serve our customers with the most various machining services, CNC milling service, CNC turning service, Metal casing service, etc. No matter CNC machining is for the auto industry or technology industry. You can put your 100% faith in us. Do not hesitate to contact us.