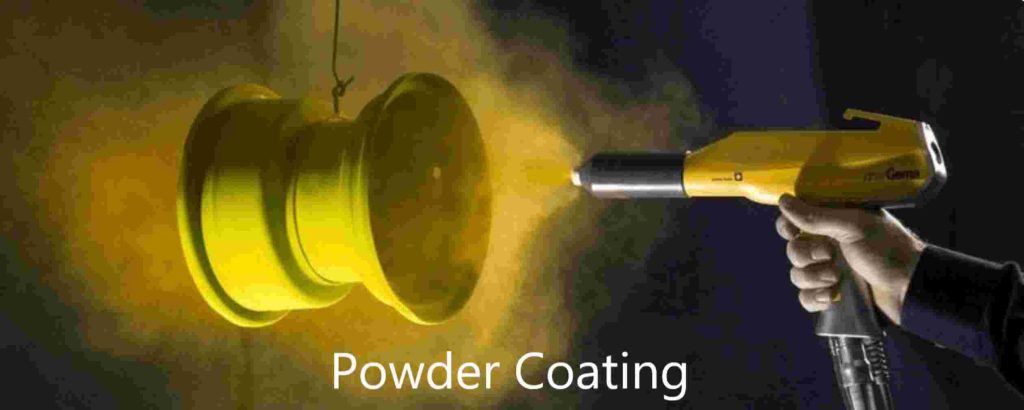

Powder coating is a type of dry finishing that uses a fine, dry powder instead of traditional liquid paint. This powder is electrostatically charged and sprayed onto the object’s surface before being baked in the oven to melt and bond, resulting in a tough, durable, and visually appealing finish. Traditional paint is less resistant to chipping, scratching, and fading than powder coating. It is resistant to harsh weather conditions, making it ideal for outdoor furniture, appliances, and automotive parts. Powder coating is available in a wide variety of colors, textures, and finishes, ranging from glossy to matte, metallic to textured. This opens up endless possibilities for customization. Understanding basic maintenance and addressing specific concerns will ensure that your powder-coated surfaces continue to function for many years.

Basic Maintenance for Powder Coated Surfaces

Proper care prevents fading, scratches, and other damage, ensuring that your powder-coated surfaces remain vibrant and attractive for years. Preventing premature damage and extending its lifespan saves you from having to pay for costly repairs or repainting later. Consider extending the warranty on your powder-coated surfaces.

Regular Cleaning

Regular cleaning is one of the most important aspects of powder-coated surface maintenance. While powder coating is a highly durable and chip-resistant finish, it, like any other surface, can accumulate dirt, grime, and environmental pollutants with time. Neglecting regular cleaning can result in several issues that jeopardize the beauty and longevity of your powder-coated investment. Surfaces exposed to harsh weather or high traffic will require more frequent cleaning than those in sheltered areas. Surfaces that are frequently touched or used require more frequent cleaning than those that are rarely used. Some powder coatings are self-cleaning or stain-resistant, requiring less frequent cleaning. Follow these simple tips to keep your powder-coated surfaces looking great for years to come:

- Clean with a soft microfiber cloth or sponge, mild soap, and warm water.

- Avoid using harsh chemicals, abrasive cleaners, or scouring pads.

- Rinse thoroughly with clean water and let dry completely.

- To remove stubborn stains, use a gentle stain remover designed for powder-coated surfaces.

Avoiding Harsh Chemicals

Avoiding harsh chemicals is an important part of basic maintenance for powder-coated surfaces because they can damage the protective and aesthetically pleasing finish. The main purpose of powder coating is to protect the underlying metal from corrosion, rust, and other environmental elements. Harsh chemicals can degrade the coating’s integrity, allowing harmful agents to enter through tiny gaps. This can result in premature rusting, pitting, or structural weakening of the metal, significantly reducing the object’s lifespan and functionality.

Here are some gentle alternatives:

- Mild Soap and Water: For routine cleaning, a simple solution of mild dish soap and lukewarm water is usually sufficient. Use a soft sponge or microfiber cloth to remove dirt and grime, then rinse thoroughly and dry with a clean towel. Consider giving your powder-coated surface a gentle spa treatment.

- Specialized Cleaners: Choose cleaning products designed specifically for powder-coated surfaces. These formulations are gentle but effective, removing dirt and grime without damaging the coating. It’s like using the right tool for the job: a gentle touch yields a delicate finish.

Addressing Specific Concerns of Powder-Coated Surfaces

Stubborn Stains

Conquering stubborn stains on powder-coated surfaces necessitates a strategic approach that balances effectiveness and gentle care. Here’s how to get rid of those pesky marks while maintaining the beauty and integrity of your powder-coated treasures:

Different stains require different tactics:

- Food and Drink Spills: These are typically the easiest to handle. Blot up any excess with a clean, absorbent cloth right away. Then, gently wipe the area with a damp cloth and a mild dish soap solution. Rinse thoroughly, then dry with a microfiber cloth.

- Grease and Oil: These require more muscle. Dampen a cloth with a degreaser, such as diluted dish soap or vinegar solution. Apply gently in a circular motion, then rinse and dry completely.

- Ink and Markers: These can be tricky. Avoid using harsh solvents such as acetone, as they can damage the powder coating. Use a gentle rubbing alcohol solution on a cotton swab and test it on an inconspicuous area first. If that does not work, consider hiring a professional cleaner.

Equip yourself with the right tools:

- Soft cloths and sponges: Avoid using abrasive materials such as scouring pads or rough towels that can scratch the powder coating. Choose microfiber cloths or soft sponges for gentle cleaning.

- Mild cleaning solutions: Use gentle dish soap, diluted vinegar, or baking soda paste.

Scratches and Abrasions

Scratches and abrasions on powder-coated surfaces can be unsightly and damage the protective layer. There are ways to deal with them, depending on the severity of the damage:

Minor Scratches

- Buffing: Simply buffing with a soft, clean cloth can often remove minor surface scratches. Use a gentle circular motion with minimal pressure.

Moderate Scratches

- Scratch-Filling Compounds: Use scratch-filling compounds designed specifically for powder coatings for deeper scratches. These compounds fill in the scratches and create a smooth surface. Apply a small amount to a soft cloth and buff gently.

Touch-Up Paint

- Matching Paint: If the scratch exposes the underlying metal, you will require touch-up paint. Look for a paint that closely matches the original powder coating color. Many powder coating manufacturers provide touch-up kits with the necessary paint and application tools.

- Applying Touch-Up Paint: Clean the area surrounding the scratch thoroughly. Apply a thin layer of paint with a small brush or the applicator included with the touch-up kit. Allow it to completely dry before adding more coats if necessary.

Professional Repair

- Severe Scratches or Large Areas: For deep scratches or extensive damage, professional repair is advised. A powder coating specialist can refinish the entire area, resulting in a smooth and durable finish.

Sun Fading

Sunlight’s ultraviolet (UV) rays are the primary causes of powder coating fading. These high-energy rays break down the pigments and resin binders in the coating, causing the color to fade over time.

Prevention is Key

- Strategic Placement: When possible, place powder-coated items in areas with less direct sunlight exposure. This could entail relocating furniture indoors during peak sunlight hours or selecting shady locations for outdoor items.

- Selective Color Choices: For surfaces that will be exposed to a lot of sunlight, choose inherently UV-resistant colors such as dark greys, browns, or beiges. These colors fade less noticeably than brighter hues.

- Protective Coatings: Consider using a UV-protective clear coat or wax on your powder-coated surfaces. These additional layers act as a protective barrier, absorbing and deflecting UV rays before they reach the underlying coating.

Remedial Measures

- Regular Cleaning: Dirt and grime can worsen the effects of sun fading. Regularly cleaning your powder-coated surfaces with mild soap and water removes these layers and keeps the coating looking brighter.

- Touch-Ups: For minor fading, touch-up paint designed for powder coatings can be used. Apply it carefully to the affected areas to restore the original color.

- Repainting: If fading is severe and touch-ups are not possible, the entire surface may need to be repainted. Consult a professional powder coating service for this, as they have the knowledge and equipment to ensure a flawless finish.

Conclusion

Remember to practice gentle cleaning, avoid harsh chemicals, and limit sun exposure. It’s not just about maintaining pristine aesthetics; it’s also about protecting the investment, functionality, and even environmental value of these stunning and long-lasting finishes. If you have any additional questions about powder coating, please get in touch with us.