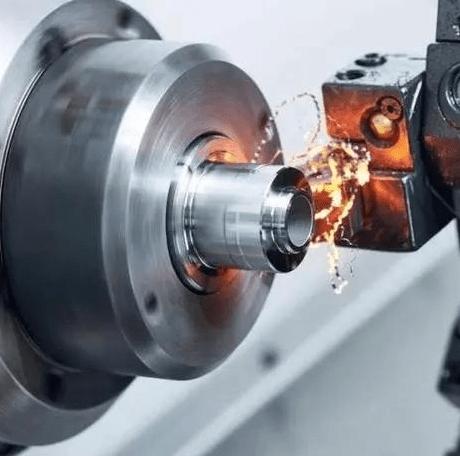

In today’s competitive manufacturing landscape, efficiency and waste reduction are critical drivers for success. CNC Turning, an advanced machining process driven by computerized automation, has emerged as a powerful solution for achieving these goals. By combining precision, speed, and optimization, CNC Turning offers significant improvements in efficiency while minimizing waste in the manufacturing process. This article explores how CNC Turning revolutionizes production, enhancing efficiency, and reducing waste.

Efficiency Through Automation in CNC Turning

One of the primary ways CNC Turning improves efficiency is through its automation capabilities. Unlike traditional manual turning methods, CNC Turning relies on computer-controlled machines that execute precise instructions with minimal human intervention. This automation translates into several key advantages:

- Continuous Operation: CNC Turning machines can run unattended for extended periods, allowing for continuous production. Once programmed, the machines execute the machining process consistently, reducing downtime between operations and optimizing production output.

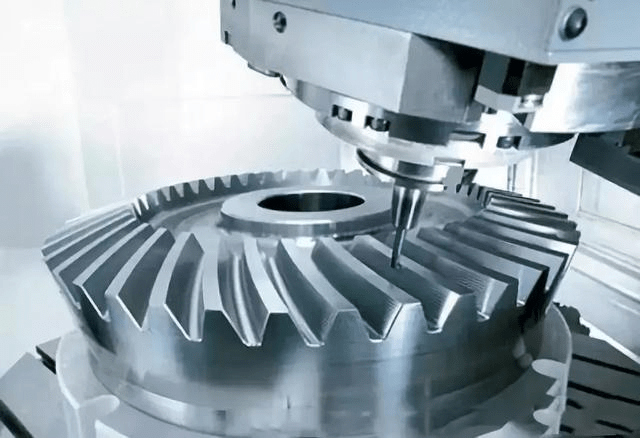

- Speed and Rapid Cycles: CNC Turning machines are capable of operating at higher speeds compared to manual turning, leading to faster production cycles. These machines can execute multiple operations simultaneously, such as cutting, facing, drilling, and threading, significantly reducing the time required to produce a finished part.

- Quick Tool Changes: CNC Turning machines enable swift and precise tool changes during the machining process. Automatic tool changers eliminate the need for manual adjustments, reducing downtime associated with tool swapping and optimizing production efficiency.

Waste Reduction Strategies in CNC Turning

CNC Turning also brings about notable waste reduction strategies, minimizing material waste and optimizing resource utilization throughout the manufacturing process:

- Accurate Programming: CNC Turning relies on computer programming to execute precise tool paths. By eliminating human errors associated with manual operation, CNC machines minimize material wastage caused by mistakes in cutting, shaping, or dimensional inaccuracies.

- Optimal Material Utilization: CNC Turning software allows for the optimization of tool paths, ensuring maximum material utilization. By strategically positioning the part and optimizing cutting paths, manufacturers can reduce scrap and material costs, making efficient use of the raw materials.

- Nesting and Multi-Part Machining: CNC Turning machines excel in nesting multiple parts within a single workpiece, a technique that minimizes material waste. Simultaneous machining of various parts from a single stock material optimizes material usage, reducing waste and maximizing productivity.

- Quality Assurance: CNC Turning ensures consistent and high-quality results, significantly reducing the need for rework or scrapping of defective parts. The precise execution of programmed instructions eliminates variations caused by human factors, ensuring that each part meets the required specifications and quality standards.

- Real-Time Monitoring and Feedback: Many CNC Turning machines are equipped with advanced sensors and monitoring systems that provide real-time data on cutting conditions, tool wear, and process performance. This data empowers operators to make informed decisions and adjustments, optimize machining parameters, and reduce waste caused by suboptimal conditions or tool failures.

By leveraging automation, accurate programming, optimal material utilization, quality assurance, and real-time monitoring, CNC Turning Service improves efficiency and reduces waste in the manufacturing process. These advantages make CNC Turning an indispensable solution for manufacturers seeking to enhance productivity, reduce costs, and deliver high-quality products in a competitive market.