Chrome finishing on aluminum is a process that enhances both the appearance and performance of aluminum products. By applying a thin layer of chrome over aluminum, manufacturers create durable, corrosion-resistant surfaces that are highly reflective and aesthetically pleasing. This finishing technique is widely used in industries ranging from automotive to aerospace, thanks to its combination of strength and style. In this article, we’ll explore the intricacies of chrome finishing on aluminum, covering the process, common challenges, applications, and maintenance requirements.

Understanding Chrome Finishing

Chrome finishing, also known as chrome plating, involves coating a metal surface with a layer of chromium. This process improves the metal’s resistance to wear, corrosion, and scratches while giving it a brilliant mirror-like finish. There are two main types of chrome plating: decorative chrome, which focuses on aesthetics, and hard chrome, which enhances durability. Decorative chrome finishes are typically thin layers that provide a sleek appearance, while hard chrome finishes are thicker and used for heavy-duty applications. The process of chrome finishing uses electroplating technology, where electrical currents deposit a thin layer of chrome onto the base material.

Chrome finish on aluminum is a specific type of electroplating where a layer of chromium is deposited on aluminum. Despite its natural resistance to rust, raw aluminum lacks the shiny, polished look many industries desire. Chrome plating solves this by giving aluminum the high-gloss, reflective surface associated with more premium metals. Additionally, chrome-plated aluminum retains the advantages of aluminum’s low density and flexibility, making it a preferred choice in automotive, aerospace, and consumer products that require a balance of strength and aesthetic appeal.

Process of Chrome Finishing on Aluminum

Since aluminum has a natural oxide layer that prevents easy adhesion of chromium, a multi-step process is typically required to achieve the chrome finish.

Surface Preparation:

Aluminum is first cleaned thoroughly to remove any dirt, grease, or impurities that may affect the adhesion of the plating.

The aluminum surface is then etched or polished to remove the natural oxide layer that forms on aluminum, ensuring the surface is ready for coating.

Nickel or Copper Plating:

Before applying the chrome layer, a base layer of nickel or copper is often deposited onto the aluminum. This step is necessary because chrome does not bond well directly to aluminum. The nickel or copper layer provides a smooth, adhesive-friendly surface for the chrome to bind with. Nickel is commonly used in decorative chrome finishes because of its shiny appearance and added corrosion resistance. Copper, on the other hand, is often used in industrial applications where enhanced conductivity or flexibility is required.

Chrome Plating:

Once the aluminum has been prepared and a base layer applied, the chrome plating process begins. Chrome is deposited using an electroplating process, where the aluminum part is submerged in a solution containing chromium ions. An electrical current is passed through the solution, causing the chromium to bond with the surface of the aluminum. The thickness of the chrome layer can be controlled, depending on the desired application. Thin layers are used for decorative purposes, while thicker layers are applied when durability is a priority.

Chrome plating adds the final layer of protection and shine to the aluminum, resulting in a sleek, mirror-like finish that is both visually appealing and functionally robust.

Common Challenges and Solutions in Chrome Finishing on Aluminum

Chrome finishing on aluminum presents several technical challenges due to the material’s specific properties. Aluminum’s high reactivity and natural oxide layer make it difficult to achieve a smooth, durable chrome finish. Below are the most common challenges encountered during chrome finishing on aluminum and the solutions to overcome them.

1. Oxidation Layer on Aluminum

Aluminum naturally forms an oxide layer when exposed to air. This layer is problematic during chrome plating, as it can prevent proper adhesion of the plating material, resulting in poor finish quality and weak durability.

Solution: The aluminum surface must be carefully prepared to remove the oxide layer before chrome plating. This is typically done by using a chemical pretreatment, such as an alkaline etch or acid dip. Once the oxide layer is removed, the aluminum part should be immediately transferred to the plating bath to prevent re-oxidation. Some manufacturers also apply a zincate layer to protect the surface and enhance adhesion during the chrome plating process.

2. Poor Adhesion of Chrome Plating

Achieving strong adhesion between chrome and aluminum can be difficult. The metal’s natural characteristics and its oxide layer can lead to weak bonding, causing the chrome layer to peel or flake off over time.

Solution: Applying an intermediate layer, such as nickel, is a common practice to improve adhesion between aluminum and chrome. After removing the oxide layer, a thin layer of nickel or copper can be electroplated onto the aluminum surface. This acts as a bridge between the aluminum and chrome layers, promoting stronger adhesion and a more uniform finish.

3. Surface Defects and Inconsistent Finish

Due to aluminum’s softness, surface imperfections such as scratches, pits, or roughness can easily affect the quality of the chrome finish. These defects may become more pronounced after the chrome plating process, leading to an uneven appearance.

Solution: Surface preparation is crucial for achieving a flawless chrome finish. Aluminum parts should be polished and buffed to a mirror-like finish before the chrome plating process begins. Any imperfections must be smoothed out to ensure the plating adheres evenly across the surface. Some manufacturers also use filler materials to repair any deeper scratches or imperfections prior to polishing.

4. Corrosion Resistance Issues

Aluminum is prone to corrosion when exposed to certain environmental factors, particularly in areas where the chrome finish may be thin or compromised. The presence of small pores or defects in the chrome layer can lead to oxidation of the underlying aluminum, compromising both the appearance and integrity of the part.

Solution: To improve corrosion resistance, it’s essential to apply a thick, even layer of chrome during the plating process. A multi-layer chrome finish, with additional protective layers like copper or nickel, can help to seal the surface more effectively, preventing moisture or air from reaching the aluminum. Regular inspections and maintenance, such as re-coating areas where the chrome layer has worn thin, are also important for long-term durability.

5. Chromium Plating Thickness Control

Controlling the thickness of the chrome layer on aluminum can be difficult, especially when uniformity across complex shapes or detailed parts is required. An uneven chrome coating can lead to an inconsistent appearance, as well as weaker protection in some areas.

Solution: Precision in the plating process is key to achieving uniform chrome thickness. This can be managed through careful control of the electroplating bath parameters, such as current density, temperature, and plating time. In cases of complex part geometries, specialized techniques like “rack plating” or the use of auxiliary anodes can help ensure even distribution of the chrome layer.

6. Environmental and Health Concerns

Chrome plating involves the use of hazardous chemicals, such as hexavalent chromium, which poses risks to both workers and the environment. Improper disposal or handling of these chemicals can lead to serious health hazards and environmental contamination.

Solution: To mitigate environmental and health concerns, many manufacturers are shifting towards safer, more eco-friendly alternatives, such as trivalent chromium plating. This method offers similar aesthetic and performance benefits while being less toxic and harmful. Additionally, adopting best practices for chemical handling, including proper ventilation, protective equipment, and waste management, can significantly reduce the risks associated with traditional chrome plating methods.

By addressing these challenges with the appropriate solutions, chrome finishing on aluminum can be performed more efficiently, leading to a durable, high-quality finish that meets industry standards.

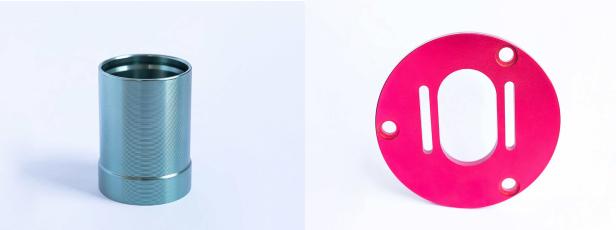

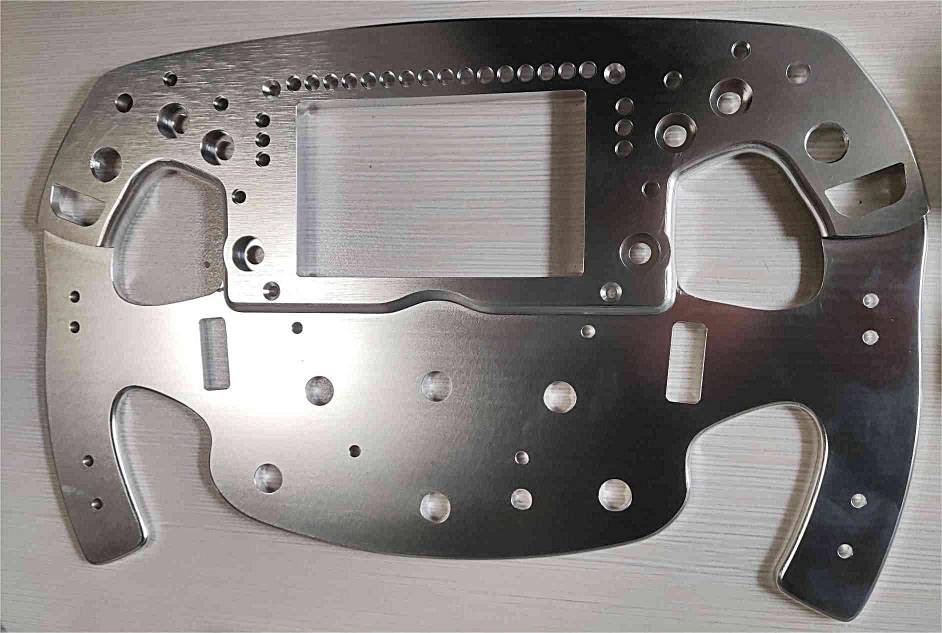

Applications of Chrome Finishing on Aluminum

Chrome finishing on aluminum is used across many industries due to its aesthetic and functional benefits:

| Industry | Representative Parts |

| Automotive | Wheels (rims), Trim pieces (grilles, mirrors, badges), Bumpers, Exhaust tips, Door handles |

| Motorcycle | Exhaust pipes, Frames, Engine covers |

| Bicycles | Frames, Handlebars, Forks |

| Household Fixtures | Faucets, Showerheads, Light fixtures, Furniture accents (table legs, chair arms) |

| Appliances | Oven knobs, Refrigerator handles, Toaster exteriors |

| Industrial Equipment | Hydraulic cylinders, Machine tool components, Valves and pistons, Mold components |

| Consumer Electronics | Phone and laptop bodies (decorative trims), Audio equipment casings, Headphone components |

| Marine | Boat cleats, Rails and fittings, Steering wheels |

| Aerospace | Aircraft interior fittings (handles, latches), Landing gear components |

| Plumbing | Pipe fittings, Valves |

| Furniture | Chrome-plated chair legs, Table frames |

Maintenance and Care for Chrome-Finished Aluminum

Maintaining chrome-finished aluminum is relatively simple, but regular care is important to preserve its shine and protect it from damage:

- Regular Cleaning: Gently clean the surface with a mild detergent and soft cloth to remove dirt and grime. Avoid abrasive cleaners or harsh chemicals that can scratch the chrome finish.

- Waxing: Applying a protective wax coating can help to enhance the shine and provide additional protection against corrosion and scratches.

- Avoid Harsh Chemicals: Avoid exposing chrome-finished aluminum to harsh chemicals, such as chlorine, bleach, or acids, which can damage the finish.

Chrome finishing on aluminum is a multi-step process that transforms aluminum into a durable, visually appealing material suitable for a wide range of industries. From surface preparation to electroplating, each step plays a vital role in ensuring the longevity and quality of the final product. While there are challenges involved, proper techniques can overcome these hurdles, resulting in a premium chrome finish that enhances both the form and function of aluminum parts. If you are looking for a supplier who providing chrome plating aluminum service, please feel free to contact JTR. We can provide you quality CNC machining and surface finishing service. Please rest assured that we will take all your needs seriously.