How is 3D Printing Classified?

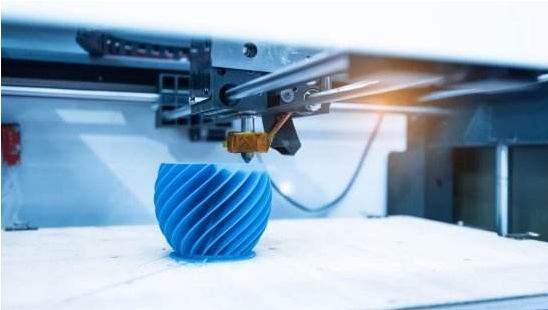

In this technology, standard filamentous materials are fed into the nozzle, heated and melted in the nozzle, extruded from the heated nozzle, and the extruded molten polymer filaments are solidified into filaments of hundreds of microns in an external low-temperature environment. According to the predetermined trajectory of each layer of the part, the melt deposition is carried out at a fixed rate to form a 3D entity. The printing materials used are polylactic acid and ABS plastic.

The application of SLA is very extensive, and the material used is photosensitive resin. The print head is a laser spot. By irradiating the laser spot into the photocurable resin (focusing on the surface of the photocurable material with a specific wavelength and intensity of laser light), through the control of the optical path, the laser spot can quickly move in the resin to print a line, Then solidify in the order from line to surface to complete one layer, and then the lifting platform moves the height of one layer in the vertical direction, and then solidifies another layer so that the layers are superimposed to form a three-dimensional entity.

The materials used are powder materials such as nylon powder and metal powder. The powder is turned into a tightly bound whole by sintering, then covered layer by layer under laser scanning, and finally formed. Then after 12-14 hours of cooling, the remaining powder can be recycled and reused.

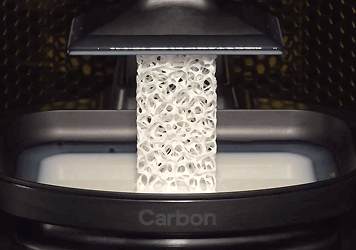

- Digital Light Processing (DLP)

The material used is a photosensitive resin. Using a high-resolution digital light processor (DLP) projector to cure the liquid photopolymer, the DLP chip projects a cross-sectional image of the printed layer onto the resin, which hardens the exposed material. The platform slowly rises vertically from the resin vat and builds each layer, all points in each layer are cured at the same time, and the layers are printed faster.

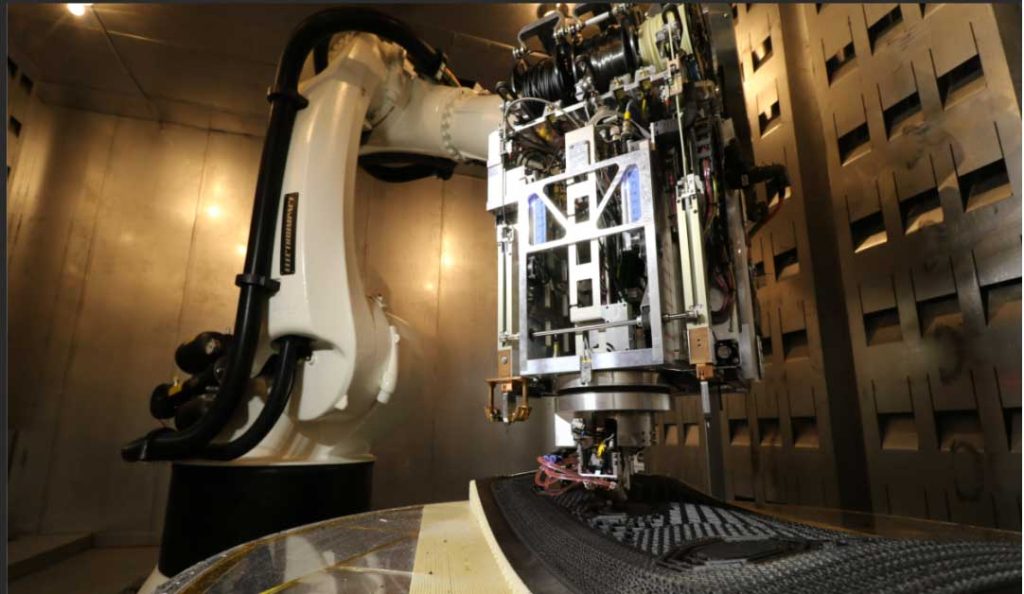

- Selective Laser Melting (SLM)

The materials used are titanium alloy, cobalt-chromium alloy, stainless steel, and aluminum alloy. SLM molding uses a laser to melt and bond materials to form multi-purpose 3D parts.

- Multiple Jet (MJP)

MJP technology is to print a thin layer of liquid plastic that can be cured by UV light on a flat platform. And use a waxy material as a support during the printing process. Cured layer by layer under UV light, with each layer completed, the modeling table descends and makes another layer, repeating until the entire part is printed.

- 3D Printing (3DP)

The software divides the 3D computer-aided design (CAD) file into thin sections, lays powder on the section, coats the connector with inkjet, and then prints layer by layer to form a three-dimensional solid model.

How are 3D Printed Materials Classified?

- Polymer material

Polymer materials are currently the most widely used class of materials in 3D printing. Polymer materials used in FDM equipment have excellent strength, hardness, heat resistance, impact resistance, and aging resistance. Common polymer materials are acrylonitrile-butadiene-styrene copolymer (ABS), polyamide (PA), polycarbonate (PC), polyphenylene sulfone (PPSF), polyether ether ketone (PEEK), etc.

ABS is the most common printing material for FDM printing technology, and PLA plastic filament is a very common printing material.

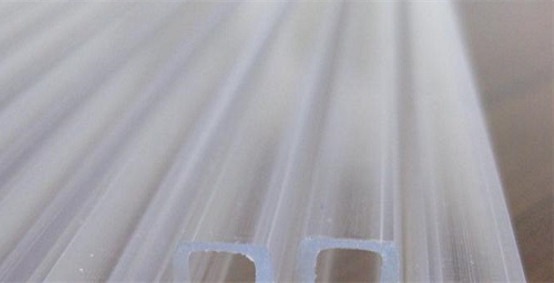

- Photosensitive material

The photosensitive resin has a fast curing speed and excellent surface drying performance. Resin is an important raw material for SLA light-curing molding technology. After molding, the appearance of the product is smooth, with a wide variety of changes, and it can be transparent or translucent frosted state. It can be used for filling and restorative materials commonly used in dentistry.

- Metallic material

At this stage, the market share of 3D printing metal materials is small, but the development speed is fast. These materials exist in the form of metal powder, metal foil, and metal wire, and common metal materials include titanium alloy, stainless steel, cobalt-chromium alloy, and aluminum alloy. Gold, silver, and other precious metal powder materials can also be used to print jewelry or artwork.

- Ceramic Materials and Composites

Ceramic materials have the advantages of low density, high strength, high hardness, high-temperature resistance, good chemical stability, and corrosion resistance. Widely used in aerospace, automotive, biology, home decoration materials, and other industries. The ceramic powder material is sintered using SLS technology. Glazed ceramic products can be used to hold food, and ceramics can also be used to print personalized mugs.

The carbon fiber material is an emerging 3D printing material. Its strength is five times that of steel, but its weight is only 1/3, and it also has the advantages of high-temperature resistance and corrosion resistance.

In addition to the above, the classification of 3D printing materials also includes cement, rock, colored gypsum materials, cellular biological raw materials, and food materials such as sugar. For example: use concrete to print houses, wood panels to print furniture, etc.

JTR has been following the development of the 3D printing industry and can also provide a variety of 3D printing services. Hope that customers in need contact JTR at any time, and we will provide you with the best solution.