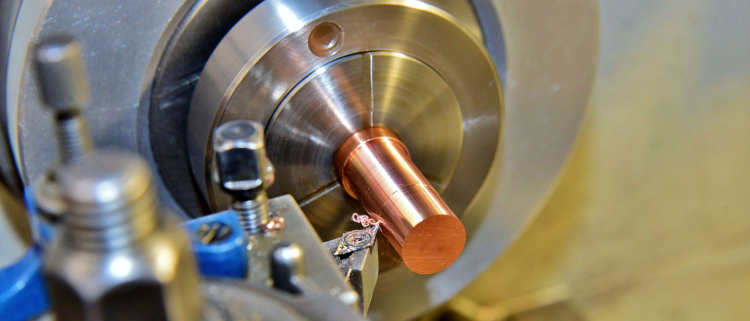

In the realm of CNC milling, the choice of materials is a critical decision that profoundly impacts the quality, durability, and performance of the final product. Among the myriad options available, galvanized steel and stainless steel stand out as popular choices for their distinct properties and applications. Understanding the nuances between these materials is essential for manufacturers and engineers seeking to optimize their CNC machining processes. This article delves into the comparative analysis of galvanized steel and stainless steel, aiming to shed light on which material might be the superior choice for CNC milling applications.

Why Choosing Galvanized Steel and Stainless Steel for CNC Milling?

Choosing between galvanized steel and stainless steel for CNC milling shares several similarities due to their inherent properties and advantages:

- Durability: Both galvanized steel and stainless steel are renowned for their durability, making them suitable for CNC milling applications where robustness is essential. They can withstand various machining processes, including cutting, drilling, and milling, without compromising structural integrity.

- Corrosion Resistance: One of the primary reasons for selecting either galvanized steel or stainless steel is their exceptional resistance to corrosion. Galvanized steel is coated with a layer of zinc, providing a protective barrier against rust and corrosion, while stainless steel contains chromium, which forms a passive oxide layer, preventing corrosion and oxidation.

- Strength: Both materials exhibit high strength-to-weight ratios, making them ideal for CNC milling projects that require components with superior mechanical properties. Whether it’s structural components or intricate parts, galvanized steel and stainless steel offer ample strength and resilience.

- Versatility: Galvanized steel and stainless steel find applications across diverse industries due to their versatility. From automotive components and machinery parts to architectural elements and kitchen appliances, both materials cater to a broad spectrum of CNC milling requirements.

- Aesthetic Appeal: While functionality is paramount, the aesthetic appeal also plays a significant role in material selection. Stainless steel, in particular, is prized for its sleek, modern appearance, making it a preferred choice for applications where aesthetics matter. Galvanized steel, with its characteristic zinc coating, also offers a distinct visual appeal that can enhance the overall look of machined components.

- Cost-effectiveness: While stainless steel typically commands a higher price compared to galvanized steel, both materials offer cost-effective solutions in the long run due to their durability and longevity. The initial investment in quality materials like galvanized steel or stainless steel often translates into reduced maintenance costs and extended service life, making them economically viable choices for CNC milling projects.

In summary, the similarities in choosing galvanized steel and stainless steel for CNC milling lie in their durability, corrosion resistance, strength, versatility, aesthetic appeal, and cost-effectiveness, making them indispensable materials for a wide range of machining applications.

Difference Between Galvanized Steel and Stainless Steel for CNC Milling

Galvanized steel and stainless steel are two distinct materials commonly used in CNC milling, each with its own set of properties, cost considerations, and machinability factors. Here’s a comparison between the two based on these aspects:

1. Material Properties:

Galvanized Steel:

Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion. It is less corrosion-resistant compared to stainless steel and is primarily chosen for its economical cost and moderate durability. Galvanized steel can have varying levels of strength depending on its composition and treatment. It tends to be relatively strong and rigid, making it suitable for various structural applications.

Stainless Steel:

Stainless steel is an alloy of steel with a minimum of 10.5% chromium content, which forms a passive layer of chromium oxide, providing excellent corrosion resistance. It is highly resistant to corrosion, rust, and staining, making it ideal for applications where exposure to moisture or harsh environments is a concern. It comes in various grades, each offering different levels of corrosion resistance, strength, and other properties.

2. Cost Considerations:

Galvanized Steel:

Galvanized steel is generally more cost-effective compared to stainless steel. It is often chosen for applications where corrosion resistance is not the primary concern, but strength and affordability are important factors.

Stainless Steel:

Stainless steel tends to be more expensive due to its higher production costs and superior corrosion resistance. While the initial cost of stainless steel may be higher, its long-term durability and resistance to corrosion can make it cost-effective in certain applications where maintenance and replacement costs are taken into account.

3. Machinability:

Galvanized Steel:

Galvanized steel is generally machinable using standard CNC milling processes. However, the presence of the zinc coating may cause increased tool wear and may require adjustments to cutting parameters. Proper cooling and lubrication techniques should be employed to ensure efficient machining and to mitigate the risk of overheating and tool damage.

Stainless Steel:

Stainless steel can be more challenging to machine compared to galvanized steel due to its hardness and toughness. Certain grades of stainless steel, such as austenitic stainless steels (e.g., 304, 316), can work harden during machining, requiring appropriate tooling and cutting strategies. Carbide tooling and coolant/lubricant are often used to improve the machinability of stainless steel and to extend tool life.

Here’s a conclusion comparison between galvanized steel and stainless steel for CNC milling:

| Aspect | Galvanized Steel | Stainless Steel |

| Material Properties | Coated with zinc for corrosion protection | Contains chromium for corrosion resistance |

| Moderate corrosion resistance | Excellent corrosion resistance | |

| Varies in strength depending on treatment | Various grades available with different properties | |

| Cost Considerations | Generally more affordable | Typically more expensive due to corrosion resistance |

| Machinability | Machinable with standard CNC milling processes | Can be more challenging to machine due to hardness and toughness |

| May require adjustments due to zinc coating | Tooling and cutting strategies needed to prevent work hardening |

In summary, while both galvanized steel and stainless steel have their respective advantages and disadvantages, the choice between them for CNC milling depends on the specific requirements of the application, including considerations of cost, corrosion resistance, and machinability.

Conclusion

In the dynamic landscape of CNC milling, the selection of materials such as galvanized steel and stainless steel holds paramount importance. While both materials possess unique attributes and advantages, the choice ultimately hinges on the specific requirements of the application, budget considerations, and desired performance characteristics. Galvanized steel offers commendable corrosion resistance and cost-effectiveness, making it suitable for a wide array of applications. On the other hand, stainless steel’s exceptional durability, hygiene, and aesthetic appeal render it indispensable in industries demanding uncompromising quality standards. By carefully weighing the inherent properties and trade-offs associated with each material, engineers can make informed decisions to enhance manufacturers’ efficiency and efficacy of their CNC milling processes.