Epoxy sheets, renowned for their durability, rigidity, and resistance to various environmental factors, have found increasing applications in numerous industries. From automotive components to industrial machinery, the demand for precision-cut epoxy parts is on the rise. CNC machining, with its unparalleled accuracy and efficiency, has emerged as the preferred method for processing these materials. This article delves into the specifics of CNC machining epoxy sheets, covering the essential tools, techniques, and safety tips to ensure successful and safe projects.

What are the Epoxy Sheets?

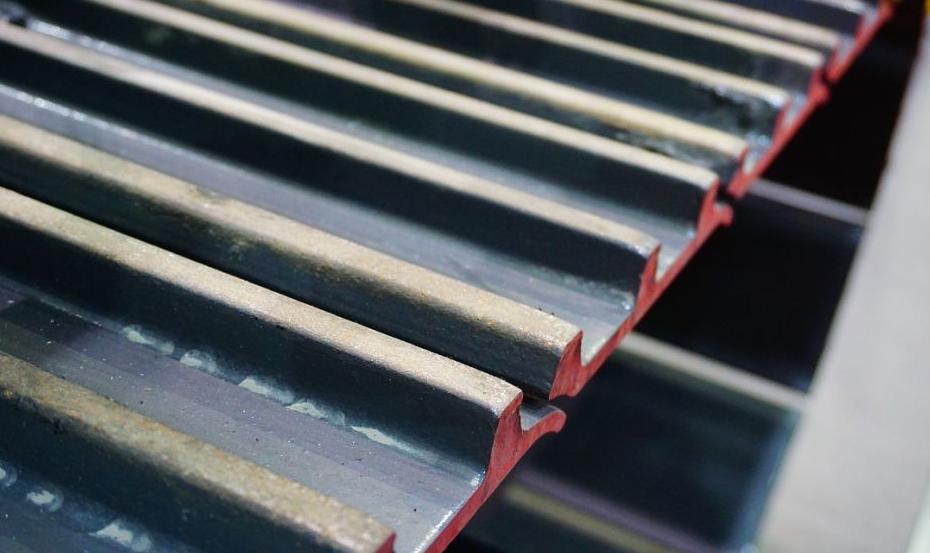

Epoxy sheets are made from epoxy resin, a type of polymer that hardens when mixed with a hardener or curing agent. The resin is typically reinforced with materials like fiberglass, carbon fiber, or other synthetic fibers to enhance its mechanical properties.

Properties of Epoxy Sheets

Epoxy sheets exhibit a range of desirable properties that make them suitable for various applications:

- High Strength-to-Weight Ratio: Epoxy sheets are strong yet lightweight, making them ideal for structural applications where weight is a concern.

- Electrical Insulation: Excellent dielectric properties make epoxy sheets suitable for electrical and electronic applications.

- Chemical Resistance: Epoxy sheets resist many chemicals, including solvents and acids, making them ideal for harsh environments.

- Thermal Stability: They maintain their properties over a wide range of temperatures, providing stability in both hot and cold conditions.

- Moisture Resistance: Epoxy sheets are resistant to moisture, preventing degradation and maintaining performance in humid conditions.

Common Applications of Epoxy Sheets

The unique properties of epoxy sheets make them versatile and suitable for a variety of industries:

- Aerospace: Used in aircraft components due to their high strength-to-weight ratio and thermal stability.

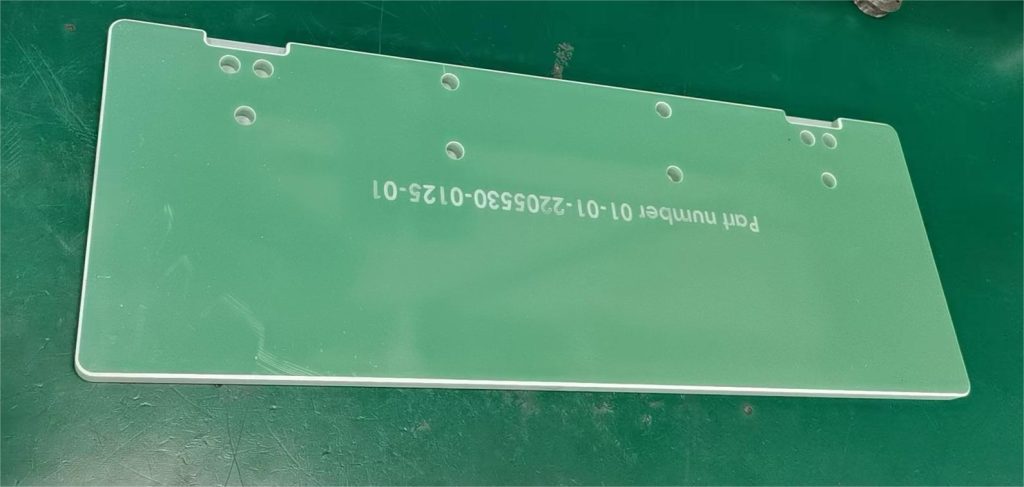

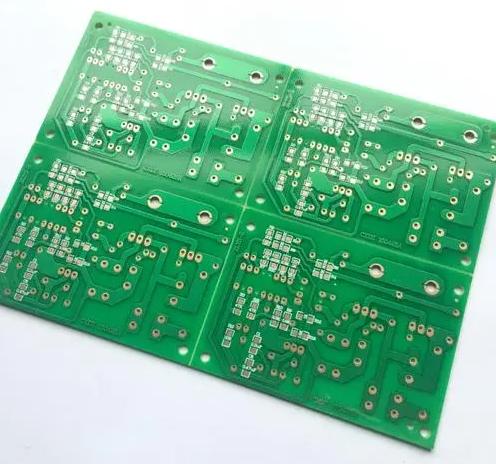

- Electronics: Utilized as insulating materials in circuit boards, transformers, and other electronic components.

- Automotive: Employed in manufacturing lightweight, durable parts such as panels, brackets, and supports.

- Marine: Used in boat hulls and other marine structures due to their resistance to moisture and corrosion.

- Construction: Applied in creating high-strength, lightweight structural components and reinforcing materials.

Epoxy sheets are indispensable in many industries due to their superior properties, including strength, electrical insulation, chemical resistance, thermal stability, and moisture resistance. Understanding their composition, properties, and applications helps in selecting the right material for specific projects and ensuring optimal performance.

Essential Tools for CNC Machining Epoxy Sheets

When it comes to CNC machining epoxy sheets, the right tools are critical for achieving precision, efficiency, and high-quality results. This section covers the various CNC machines, tools, and maintenance practices necessary for effective machining of epoxy sheets.

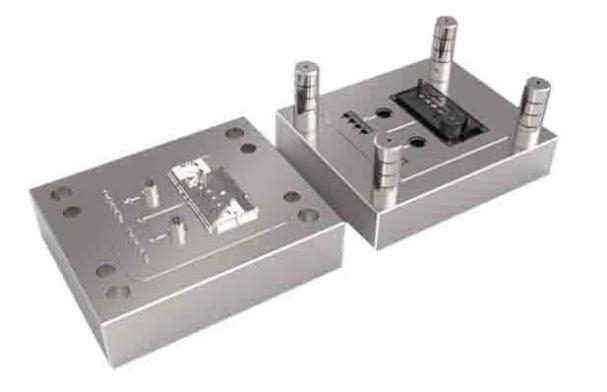

CNC Machines

- CNC Routers: CNC routers are ideal for cutting and shaping epoxy sheets. They offer high speed and precision, making them suitable for intricate designs and detailed work.

- CNC Mills: CNC mills are more robust and can handle heavier cutting operations. They are suitable for thicker epoxy sheets and more demanding machining tasks.

CNC Tools

| Tools | Features |

| End Mills | Used for cutting and shaping; Available in various sizes and geometries; Carbide-tipped or diamond-coated for durability and sharpness |

| Drill Bits | Used for creating holes; Made from high-quality materials to withstand abrasive nature of epoxy |

| Router Bits | Used for edge finishing and detailed cutting; Carbide-tipped or diamond-coated for precision and durability |

Selecting the Right Tools

- Material: Tools should be made from durable materials like carbide or diamond coatings to handle the abrasive nature of epoxy sheets.

- Geometry: The geometry of the tool (such as the flute design) should be suitable for cutting epoxy without causing excessive wear or heat buildup.

- Size: Select the appropriate size based on the thickness and complexity of the epoxy sheet project.

Techniques for CNC Machining Epoxy Sheets

Successful CNC machining of epoxy sheets involves a combination of factors, including feed rate, spindle speed, toolpath, and cutting depth. Key techniques include:

- Tool Path Programming: Accurate toolpath programming is crucial for achieving the desired shape and dimensions. CAM software can be used to generate efficient toolpaths.

- Feed Rate and Spindle Speed: Optimal feed rate and spindle speed are essential for preventing tool breakage and achieving a good surface finish. Experimentation may be required to find the ideal settings.

- Coolant Application: Applying coolant during machining helps to dissipate heat, reduce friction, and improve tool life.

- Post-Machining Finishing: Depending on the application, post-machining processes like sanding or polishing may be necessary to achieve the desired surface finish.

Safety Tips for CNC Machining Epoxy Sheets

CNC machining of epoxy sheets can pose certain hazards, including the generation of dust and the risk of injury from moving machine parts. Adhering to safety guidelines is paramount:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, hearing protection, and a dust mask.

- Machine Guards: Ensure all machine guards are in place to prevent accidental contact with moving parts.

- Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button.

- Fire Safety: Have a fire extinguisher readily available and know how to use it.

- Regular Maintenance: Keep the CNC machine in good working condition through regular maintenance and inspections.

Adhering to safety guidelines and using proper protective measures ensures a safe and efficient CNC machining environment. Prioritizing safety minimizes risks and enhances productivity.

Troubleshooting Common Issues

Even with the best preparation and techniques, issues can arise during CNC machining of epoxy sheets. Knowing how to troubleshoot common problems ensures smooth operations.

| Common Issue | Description | Troubleshooting |

| Poor Surface Finish | Rough or uneven surface after machining | Check tool sharpness and replace if worn; Adjust feed rate and spindle speed; Ensure proper cooling |

| Tool Wear and Breakage | Tools wearing out quickly or breaking during machining | Use carbide-tipped or diamond-coated tools; Ensure proper tool speeds and feeds; Regularly inspect and replace tools |

| Dimensional Inaccuracies | Parts not meeting specified dimensions or tolerances | Calibrate CNC machine regularly; Check and adjust tool offsets; Ensure proper machine setup |

| Material Warping | Epoxy sheets bending or warping during or after machining | Secure the sheet properly on the machine bed; Use appropriate cutting strategies to minimize stress |

| Overheating | Excessive heat generation during machining leading to tool wear or material damage | Ensure proper cooling and lubrication; Adjust feed rates and spindle speeds to reduce heat generation |

| Tool Marks | Visible marks left by the tool on the machined surface | Use proper finishing tools and techniques; Ensure tools are sharp and properly set up |

| Dust and Fume Management | Excessive dust and fumes affecting visibility and safety | Use dust extraction and ventilation systems; Wear appropriate PPE such as masks and goggles |

| Machine Vibration | Excessive vibration during machining affecting precision and surface finish | Check machine setup and ensure it is stable; Use balanced tools and proper cutting parameters |

| Brittle Material Handling | Epoxy sheets cracking or breaking during handling and machining | Handle sheets carefully to avoid stress; Use appropriate feed rates and cutting strategies |

| Inconsistent Cutting | Inconsistent or uneven cuts, leading to variations in part quality | Ensure proper tool setup and alignment; Regularly check and maintain machine calibration |

Effective troubleshooting requires a proactive approach to identifying and resolving issues. Regular maintenance, proper handling, and timely interventions keep the machining process smooth and efficient.

Find a Professional CNC Machining Service Provider

For complex or high-volume epoxy sheet machining projects, outsourcing to a professional CNC machining service provider can be beneficial. The companies such as JTR Machinery possess the necessary expertise, equipment, and quality control measures to deliver precision parts efficiently.

Selecting a professional CNC machining service provider requires careful evaluation of their capabilities, reputation, and pricing. A good provider ensures your project is completed to the highest standards, on time, and within budget. Feel free to contact JTR, believe they will satified your needs.