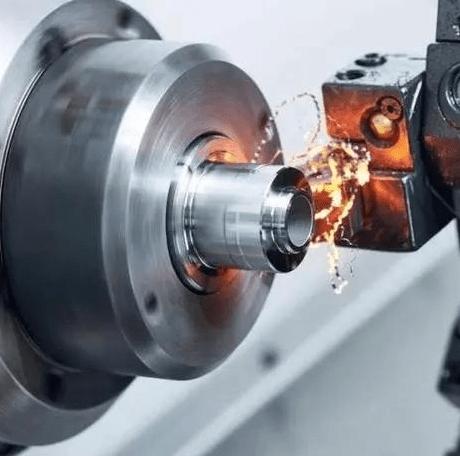

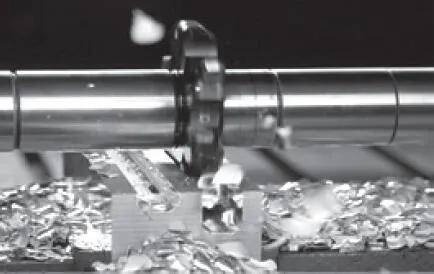

CNC turning has long been a reliable method of producing precise and functional brass parts. However, for many applications, adding a sense of permanence and detail is essential. This is where laser markings come in. Laser marking, which uses a focused beam of light, provides a non-contact and highly accurate method for etching information and designs onto brass cnc parts. But why would you choose laser marking over other methods? What factors influence the final outcome? Today we will talk about laser marking for CNC-turned brass parts, discussing its benefits, key considerations, and practical applications.

Why Use Laser Marking on CNC-Turned Brass Parts?

Laser marking provides significant benefits for CNC-turned brass components. Let’s go over each benefit in more detail:

1. Permanence: Markings that Last a Lifetime

Unlike traditional methods such as ink printing or etching, laser marking permanently changes the surface of the brass. The laser beam interacts with the material, either vaporizing it for deep engraving or producing a controlled color change. This results in a mark that is extremely resistant to:

- Abrasion: Scratches, wear, and tear will not affect the marking.

- Chemicals: Harsh cleaning solutions or accidental exposure will not harm the data.

- Heat: The marking can withstand extreme temperatures without fading or peeling.

Laser marking is ideal for applications that require traceability and identification, such as electrical components or medical devices, due to its permanence.

2. Precision: Razor-Sharp Details for Any Design

Laser marking uses a highly focused beam, allowing for extremely precise markings. This translates into:

- Sharp lines and text: Even small fonts and intricate logos are reproduced flawlessly.

- Consistent quality: Ensures a professional and uniform appearance by providing equal attention to detail across all parts.

- Complex designs: You can accurately incorporate intricate patterns, barcodes, and QR codes.

This precision is especially useful for parts with limited space for markings or that require a high level of detail for functionality, such as instrument dials and control panels.

3. Versatility: Marking Anything You Need

Laser marking is not restricted to simple text. It provides a variety of marking options for your CNC-turned brass parts:

- Text: Part numbers, logos, company names, and instructions can all be used to convey information.

- Logos and Graphics: Precisely reproduce your brand logo or other desired graphics.

- Serial Numbers and Barcodes: Unique identifiers allow for inventory tracking, part management, and traceability.

- QR Codes: Encode valuable information in a compact format for easy scanning.

This versatility enables you to include any information required for your application, thereby improving functionality, traceability, and aesthetics.

4. Cleanliness: A Touchless Approach

Laser marking is a contactless process. The laser beam interacts with the brass surface but does not physically touch it. This provides several advantages:

- No contamination: There is no risk of introducing foreign materials or lubricants into the part, which could affect its performance.

- Minimal material removal: Shallow marking removes only a small amount of material while preserving the part’s integrity.

- Safe for delicate parts: The non-contact nature makes it ideal for delicate brass components.

This clean marking process is critical for applications requiring hygiene or part integrity, such as medical devices or electronic components.

What Factors Affect the Laser Marking Process?

The laser marking process for your CNC-turned brass parts can be fine-tuned to produce the desired results. Here’s a closer look at the factors that affect the process:

1. Laser Type: Choosing the Right Tool for the Job

Different lasers have varying wavelengths and power outputs. The following factors have a significant impact on the marking results of your brass parts:

- CO2 Lasers: These lasers have a longer wavelength (about 10.6 micrometers) and are ideal for deep engraving on brass. They remove material efficiently, leaving a clear and defined mark. However, due to the larger beam size, they may not be suitable for achieving very fine details.

- Fiber Lasers: These lasers use a shorter wavelength (around 1.06 micrometers) and produce a more focused beam. This enables precise markings with high detail and fewer heat-affected zones. They are ideal for shallow marking, annealing (controlled heat treatment to change color) and intricate designs.

- Yttrium Aluminum Garnet (YAG) Lasers: In terms of wavelength, these lasers are somewhere between CO2 and fiber lasers, and they provide an excellent balance of power and detail. They are suitable for both deep engraving and shallow markings on brass.

2. Desired Marking Depth: Tailoring the Process to Your Needs

The depth of the marking has a significant impact on the visual appearance and functionality of the mark on your brass part. Here’s how it impacts the process:

- Deep Engraving: This requires removing a large amount of material from the surface. Higher laser power settings, often with CO2 lasers, are used to achieve this. Deep engraving produces a clear, defined mark that is extremely durable and resistant to wear. It’s ideal for applications that need high visibility or part identification, such as serial numbers.

- Shallow Marking: This produces a more subtle effect by changing the surface properties of the brass without removing much material. It is accomplished with lower power settings, frequently employing fiber lasers. Shallow markings can discolor the surface, create a matte finish, or cause a minor textural change. It is appropriate for applications where aesthetics or data encoding (such as QR codes) are important.

3. Surface Finish of the Brass: A Smoother Canvas for Clear Markings

The initial surface finish of your CNC-turned brass parts can affect the laser marking process and outcome.

- Smooth Surfaces: A smooth and polished surface allows the laser beam to interact uniformly, producing clean, crisp markings with high definition. This is ideal for achieving fine details and sharp text.

- Rough Surfaces: Rougher surfaces may scatter the laser beam slightly, potentially resulting in less defined or uneven markings. However, in some cases, a rough surface can be used to achieve a specific visual effect, such as a more rustic look.

Understanding the impact of these factors enables you to work with your laser marking service provider to achieve the best settings and results for your specific application.

What Are Some Common Applications for CNC-Turned Brass Parts with Laser Marking?

CNC turning’s ability to create precise shapes, combined with laser marking’s permanent, detailed capabilities, enables a wide range of applications for CNC-turned brass parts. Let’s take a closer look at some common applications:

1. Electronic Components (Connectors, Terminals)

- Functionality: Laser marking can identify connectors and terminals using part numbers, logos, or pin configurations, ensuring proper assembly and making maintenance easier.

- Traceability: Laser-etching serial numbers or barcodes help track inventory, manage parts lists, and maintain quality control.

- Durability: Markings withstand wear and tear from repeated use and exposure to harsh environments.

2. Plumbing Hardware (Valves, Fittings)

- Identification: Laser marking clearly labels valves and fittings with their size, pressure rating, and material type, assisting with proper installation and maintenance.

- Branding: Logos and company names can be etched to increase brand recognition and add a sense of quality.

- Durability: Markings can withstand harsh chemicals, water, and cleaning solutions used in plumbing.

3. Instruments and Meters (Dials, Knobs)

- Clarity: Laser marking produces clear and precise markings on dials and knobs, allowing for accurate readings and easy operation of instruments and meters.

- Calibration Marks: Markings can indicate calibration points or measurement scales, which improves instrument accuracy.

- Aesthetics: Laser-etching of logos or decorative patterns produces a professional and visually appealing finish.

4. Architectural Hardware (Door Handles, Hinges)

- Function and Style: Laser marking can identify door handles with room numbers or building codes while maintaining a clean appearance.

- Branding: Logos or architectural firm names can be subtly etched on hinges to add a sense of brand identity.

- Durability: Markings withstand wear and tear from repeated use and retain their appearance over time.

5. Decorative Items (Plaques, Awards)

- Personalization: Custom text, logos, or images can be added to plaques and awards using laser marking, resulting in a one-of-a-kind and meaningful piece.

- Intricate Details: Laser-etching allows for a high-quality, professional finish on fine lines, patterns, and even photographs.

- Permanence: Markings remain vibrant and detailed for many years, preserving the decorative item’s value.

These are just a few examples; the possibilities for CNC-turned brass parts with laser marking are endless. This technology, with its functionality, durability, and aesthetics, is a valuable tool for a variety of industries.

Conclusion

The combination of CNC turning’s precision machining and laser marking’s permanence and detail results in a powerful tool for a variety of industries. Laser marking takes CNC-turned brass parts to a whole new level of functionality and visual appeal, from ensuring traceability on electronic components to improving the aesthetics of architectural hardware. Manufacturers can realize the full potential of this technology and produce truly exceptional brass components by understanding the factors that influence the process and the wide range of applications. And choose a reliable CNC machining supplier that will give you continued support.